Ink-jet printer and maintenance method for ink-jet printer

a technology of inkjet printer and maintenance method, which is applied in the direction of printing, other printing apparatus, etc., can solve the problems of large amount of ink to be discharged, waste of ink, and large amount of ink consumed by printing, and achieves large memory capacity and favorable ink sta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]An embodiment of the present invention will be described below by referring to the accompanying diagrams. This embodiment is an embodiment in which the present invention is applied to an ink-jet printer which is used for recording on a paper in a facsimile.

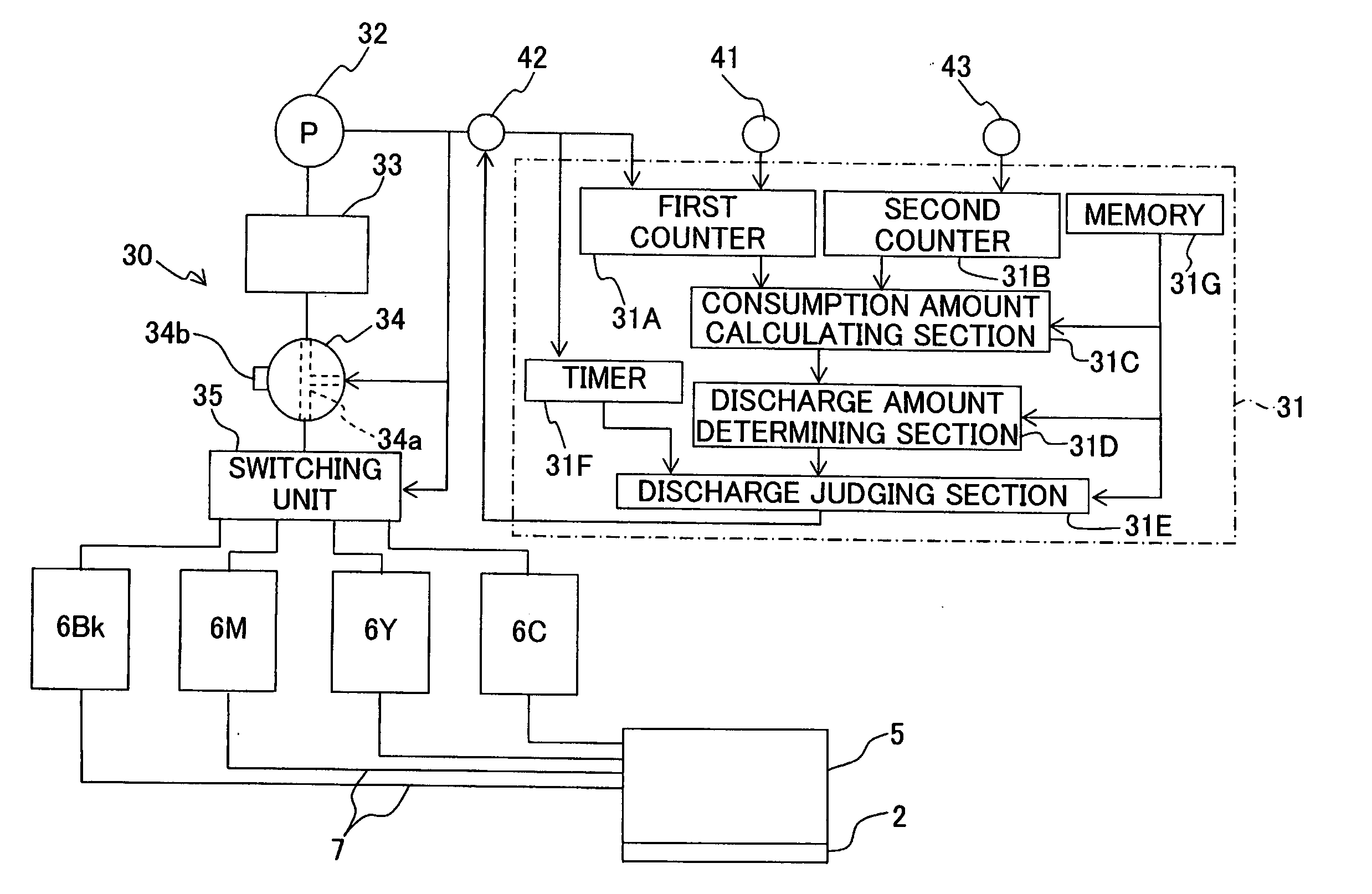

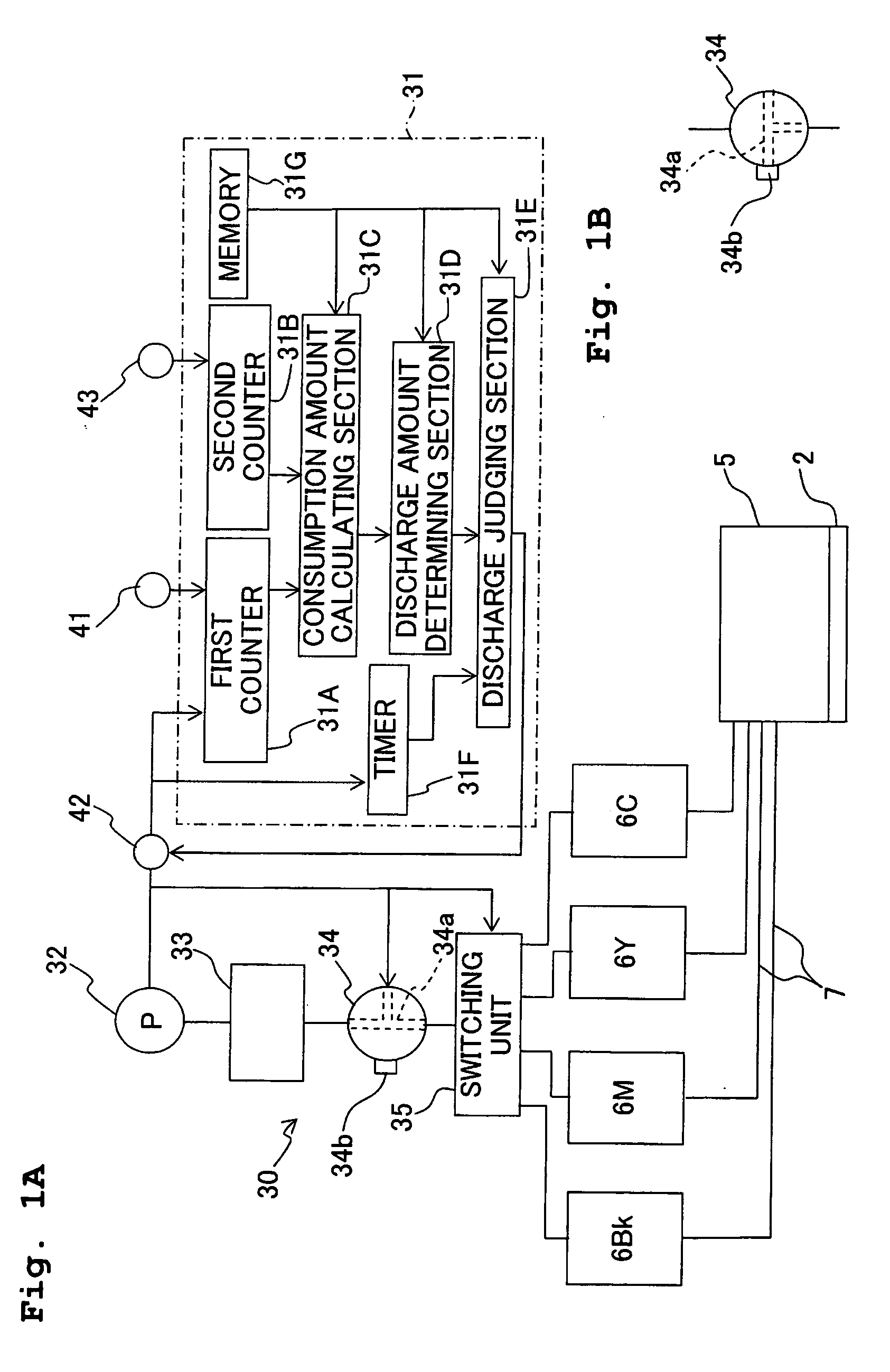

[0042]FIG. 1A is a diagram showing a schematic structure of a purge unit 30 which discharges an ink inside an ink supply system, and FIG. 1B is a diagram showing an atmosphere-opening position of an atmosphere opening valve 34.

[0043]In the ink-jet printer, the purge unit 30 (discharge mechanism) which discharges the ink inside the ink supply system includes a pressurizing pump 32 which supplies pressurized air. The pressurizing pump 32 is connected to a switching unit 35 via a surge tank 33 and an atmosphere opening valve 34 as shown in FIG. 1A. The switching unit 35 connects the pressurizing pump 32 to any one or all of ink cartridges 6Bk, 6M, 6Y, and 6C for inks of black, magenta, yellow, and cyan colors respectively. Ink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com