Foldable ovenware container and method of production

a technology of ovenware containers and ovenware, applied in the field of ovenware containers, can solve the problems of occupying a significant amount of space in the kitchen, supporting a rigid pan or similar object for stability, and conventional ovenware containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

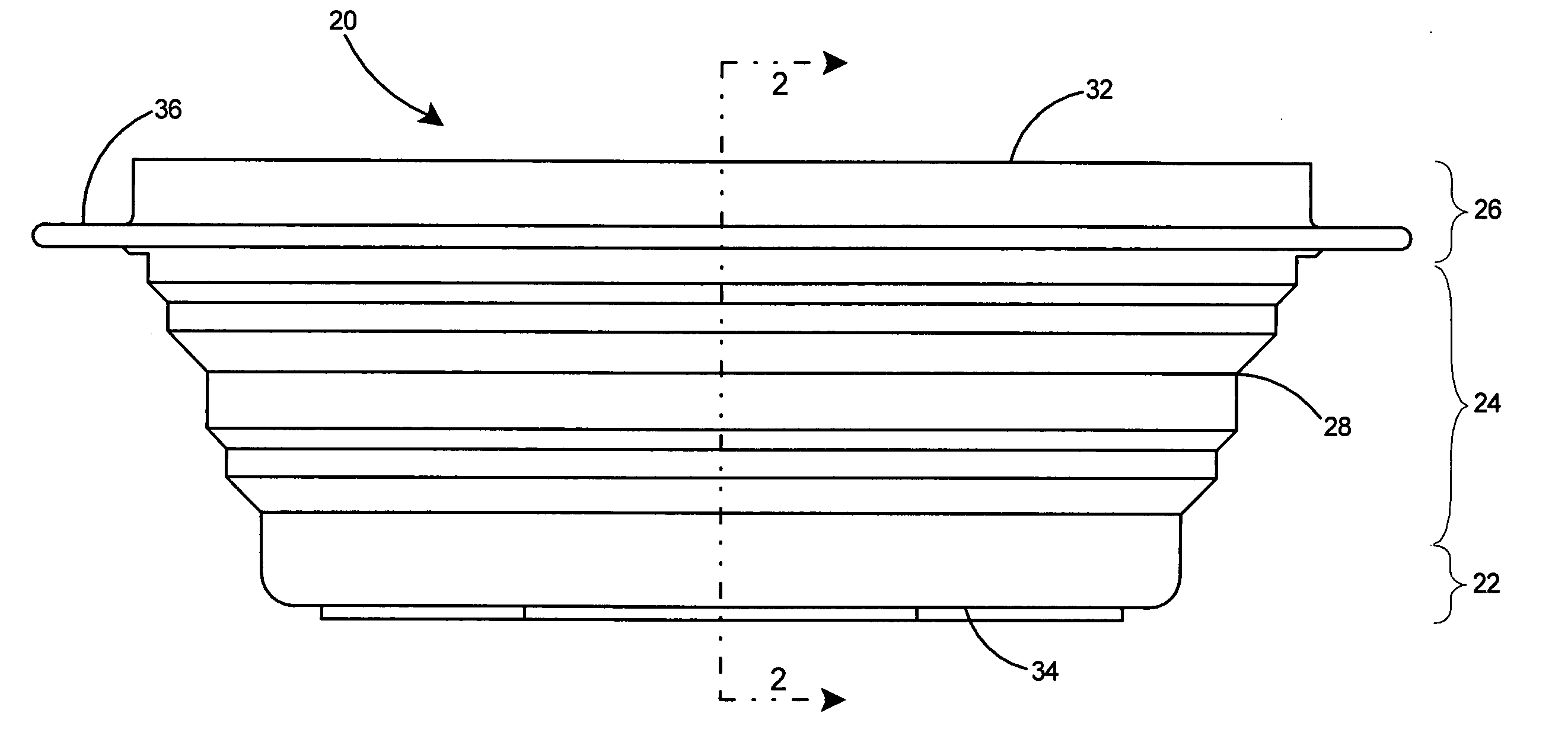

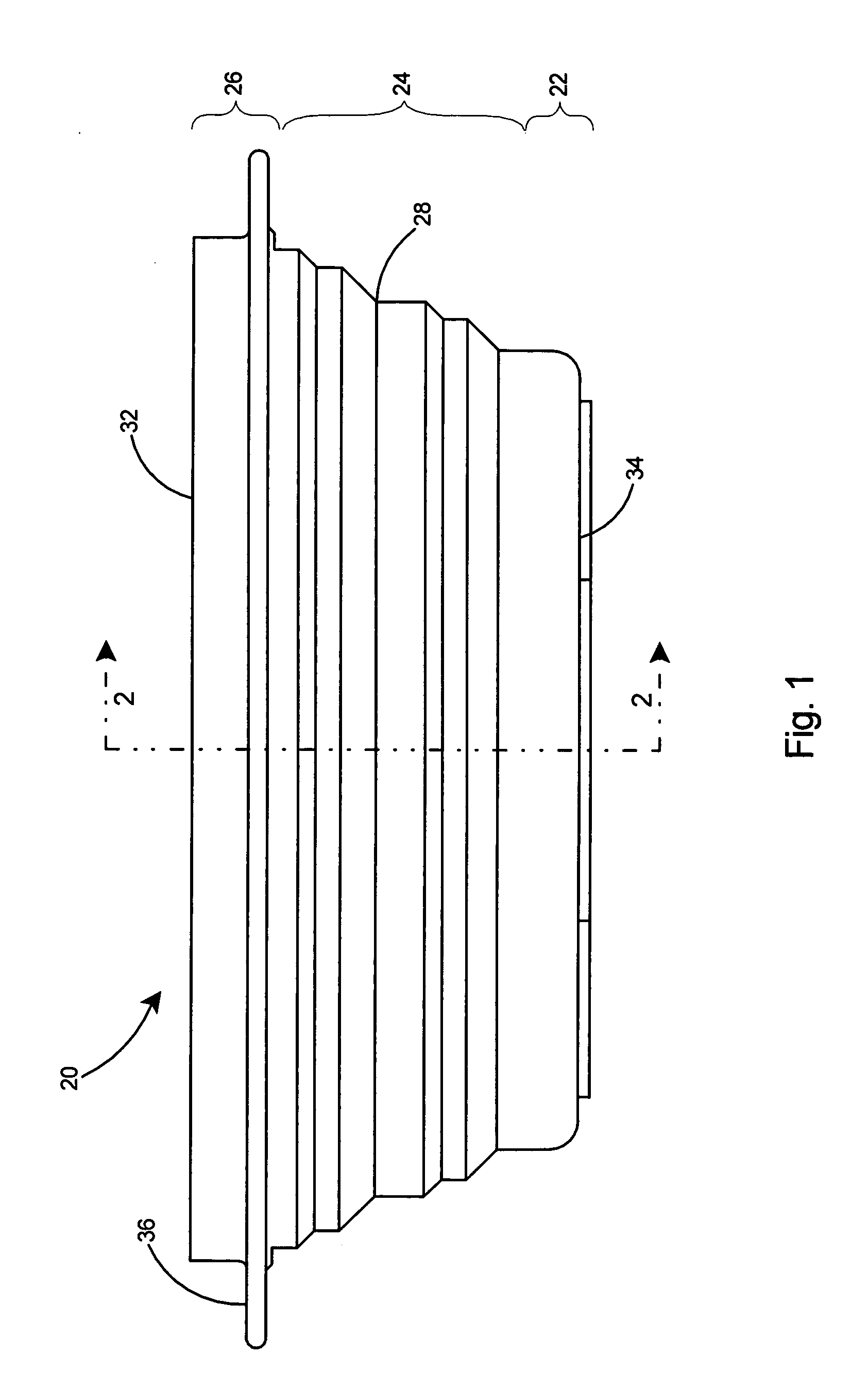

[0024]With reference to a first and preferred embodiment in FIG. 1, the present invention is an ovenware container 20 and a method of producing the ovenware container. The ovenware container includes a bottom portion 22, a middle portion 24 extending from the bottom portion 22, and a top portion 26 extending from the middle portion 24.

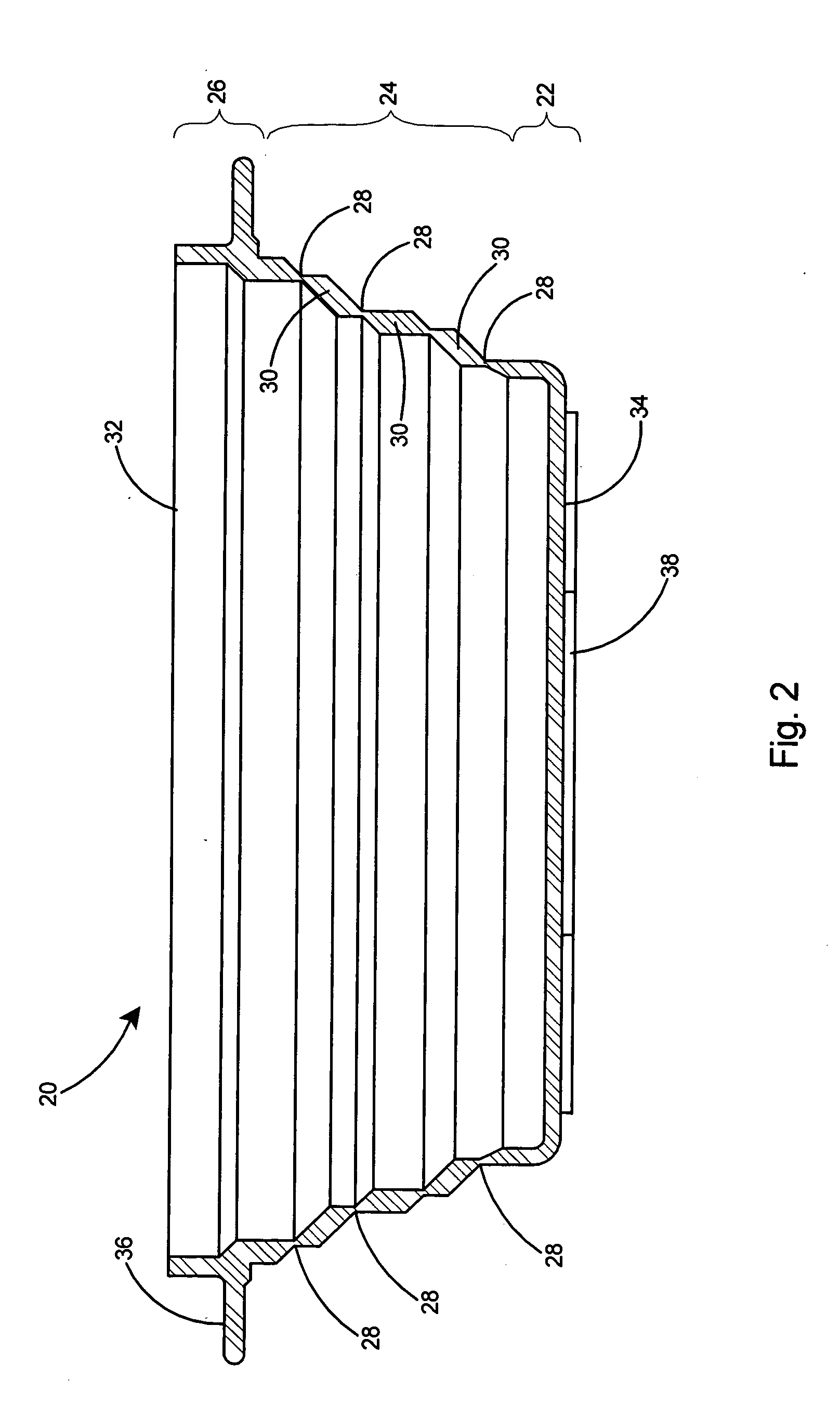

[0025]Referring to the cross-sectional view in FIG. 2, the middle portion 24 of the ovenware container 20 includes one or more thin wall sections 28 separated by thick wall sections 30. The thin wall sections 28 are planar and arranged parallel with the bottom edge 34 of the container 20. The thin wall sections 28 render the container foldable, with the container 20 capable of folding at each of the thin wall sections 28. The container 20 further includes a top edge 32, a bottom edge 34, and a handle 36 extending from the top portion 26. The container 20 can further include extensions 38 extending from the bottom edge 34. As shown in FIG. 8, the extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com