Showerhead attachment assembly

a technology for showerheads and attachments, which is applied in the direction of water installations, mechanical equipment, spray nozzles, etc., can solve the problems of affecting the vertical position of showerheads, shower arm assemblies that fail to maintain the vertical position of relatively large or heavy showerheads, and showerheads constructed of denser materials, etc., and can be difficult to adjust the position of showerheads under water pressure. , the problem of shower arm assembly not being able to meet the needs o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

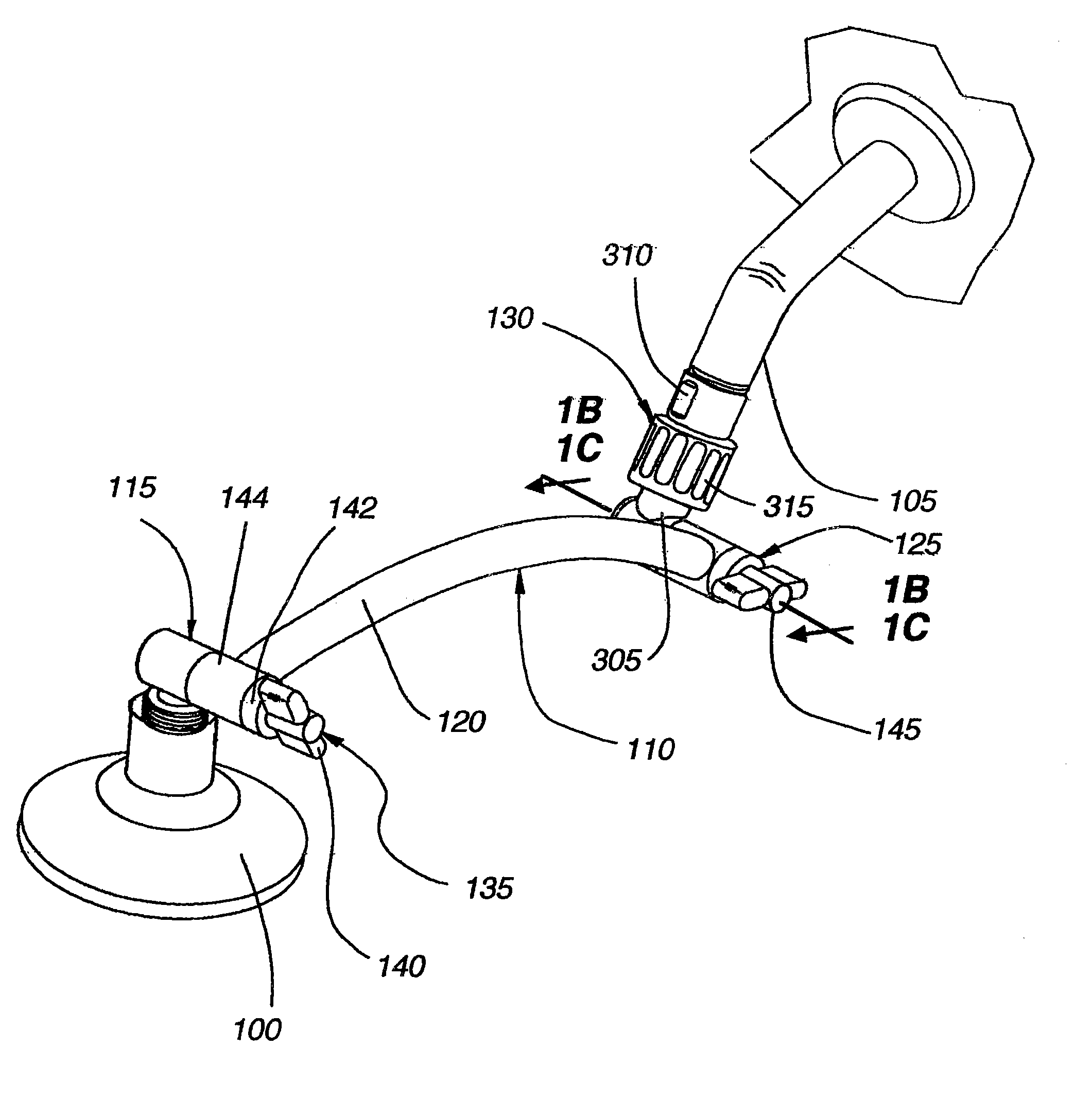

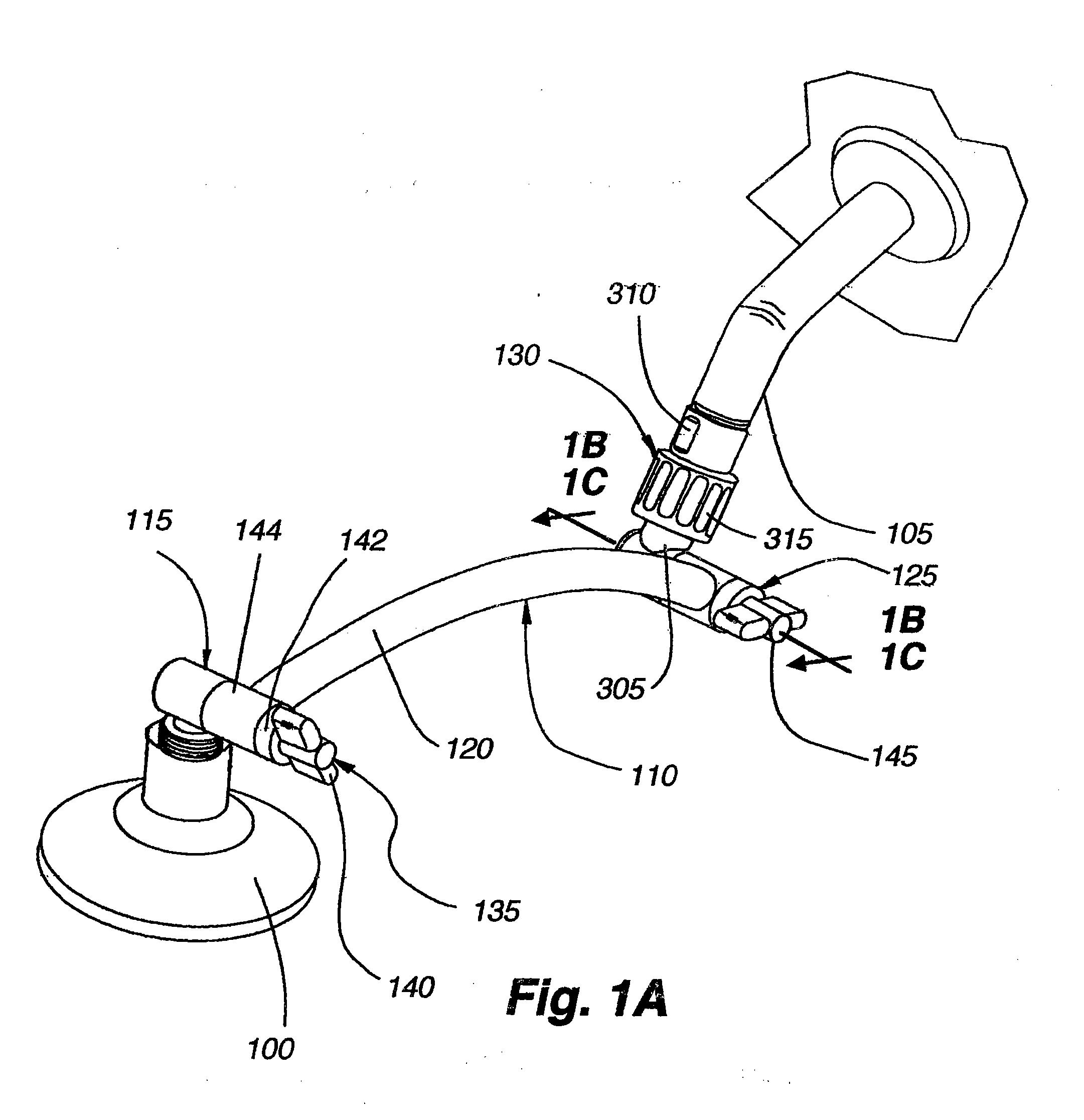

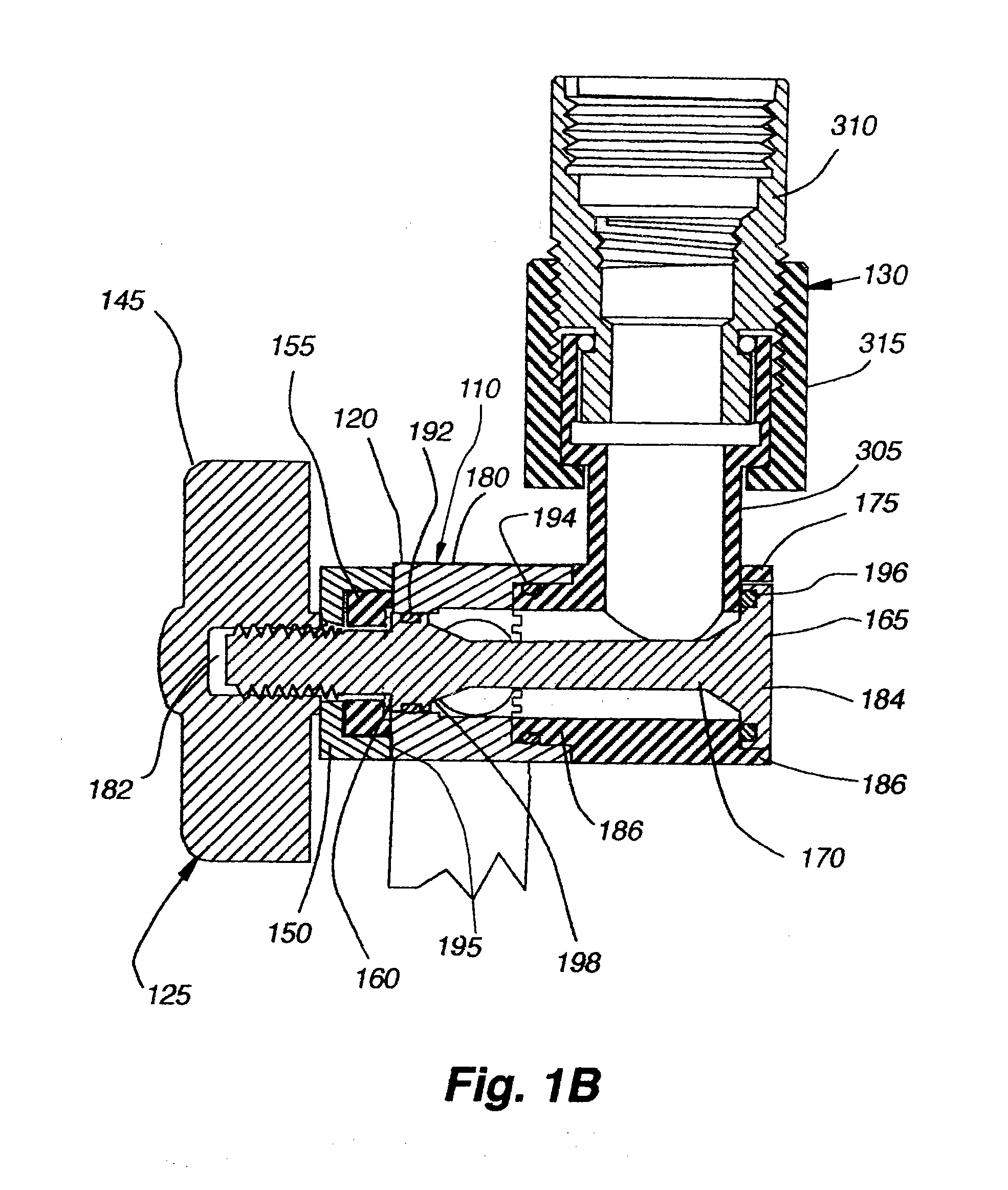

[0060]a shower arm attachment assembly 200 is depicted in FIGS. 2A-2G. This shower arm attachment assembly 200 may be used with the arm assembly 110 shown in FIG. 1A. With reference to FIGS. 2A and 2B, the shower arm attachment assembly 200 may include an arm coupling member 205 joined to a shower pipe coupling member 210. The shower pipe coupling member 210, in turn, may be joined to a shower pipe 105. The shower pipe 105 delivers water to the shower arm coupling assembly 200, and ultimately to an attached showerhead 100 (see FIG. 1), from a water heater, a water reservoir, or other suitable water source (not shown).

[0061]The arm coupling member 205 may include a shower pipe connection portion 215 for joining the arm coupling member 205 to the shower pipe coupling member 210. When joined, the arm coupling member 205 may be rotated relative to the shower pipe coupling member 210 as described in more detail below. The arm coupling member 205 may also have an arm connection portion 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com