Electrical submersible pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

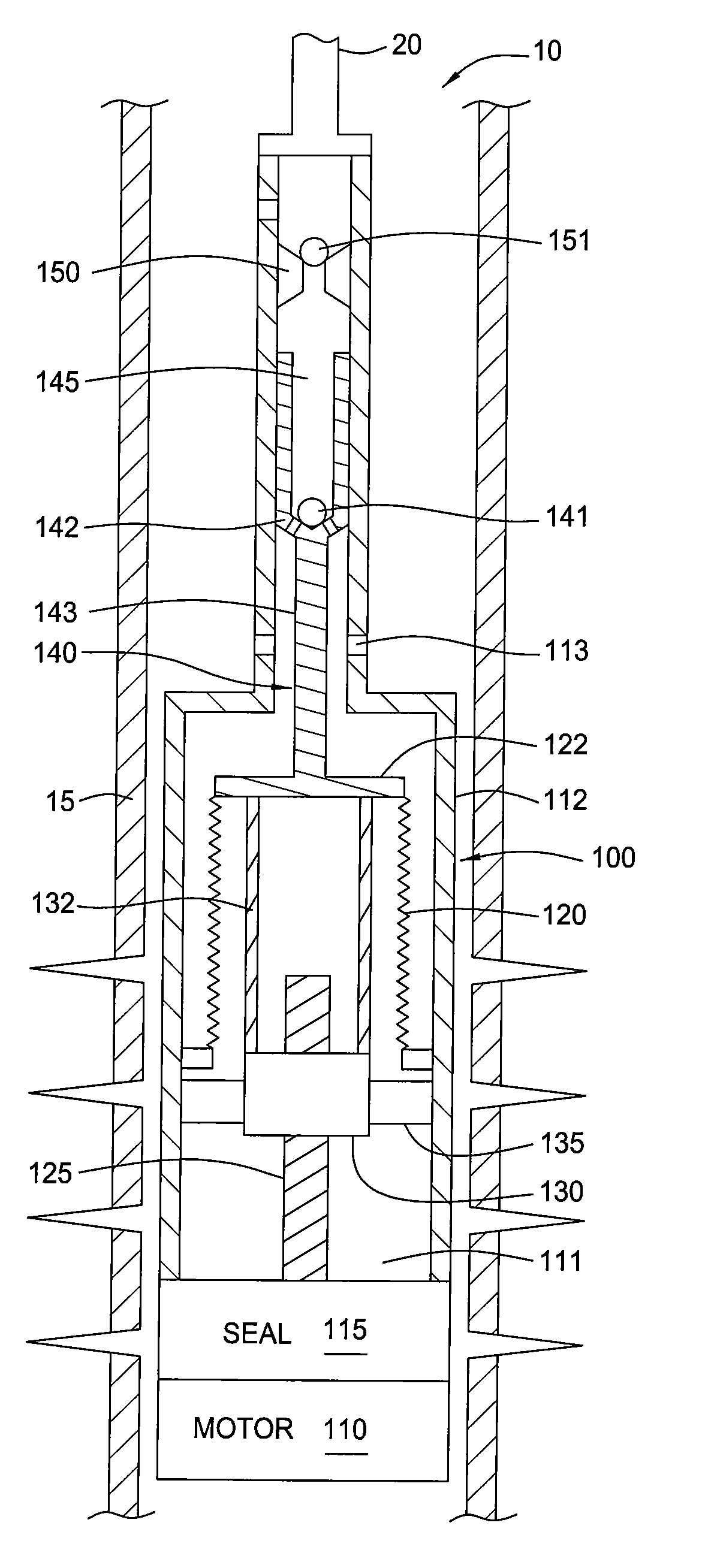

[0029]A method and apparatus for lifting fluids from a well is provided. In one embodiment, a pump assembly comprises a rotary motor adapted to actuate a reciprocating pump. The motor shaft of the rotary motor is coupled to a drive member of the reciprocating pump. In operation, rotation of the rotary motor causes reciprocation of the reciprocating pump.

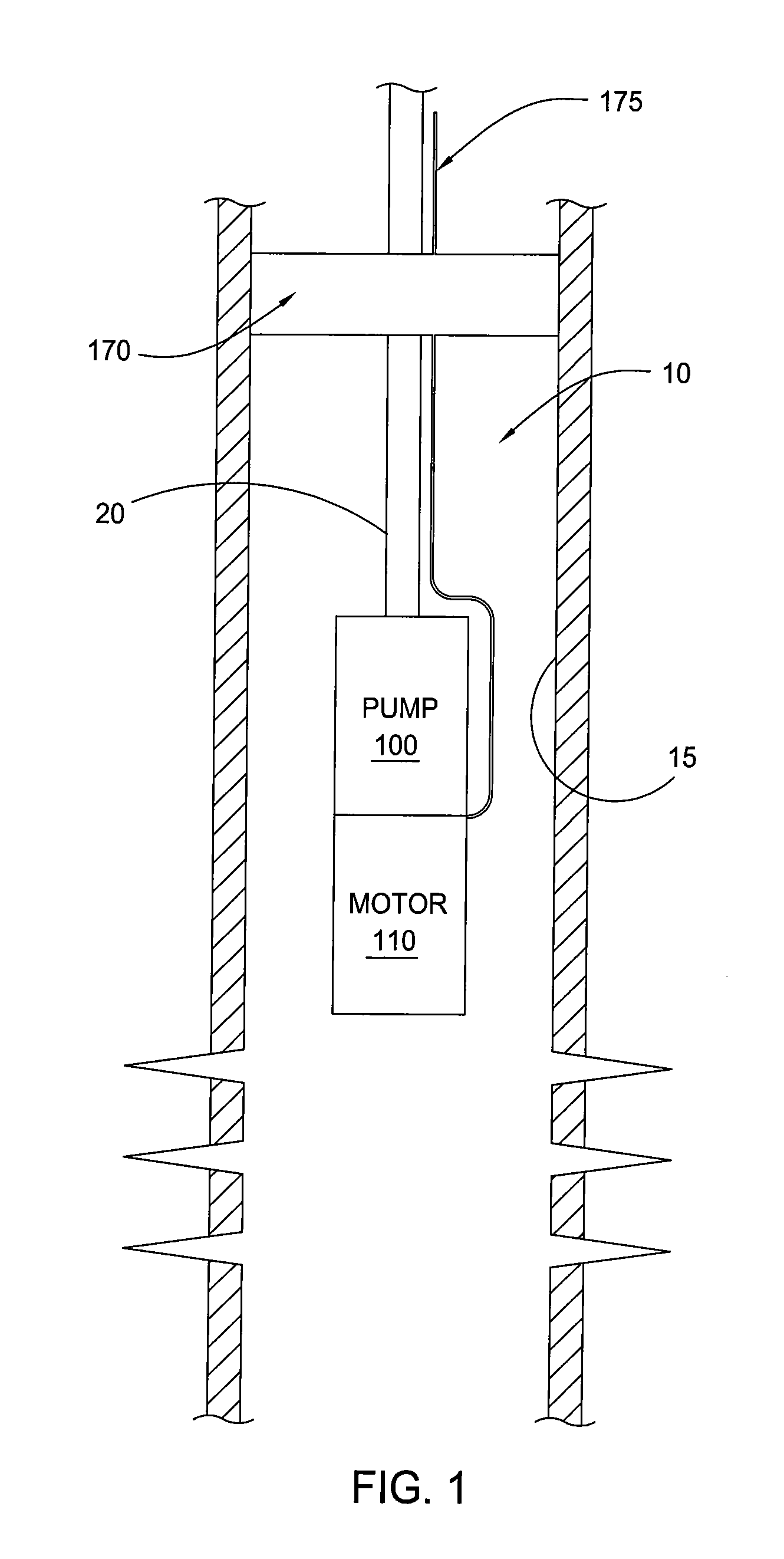

[0030]FIG. 1 is a partial cross-section view of a wellbore 10. A casing 15 is fixed in the wellbore 10 by cured cement. The casing 10 is perforated to allow the inflow of formation fluids. A string of production tubing 20 extends from the surface to a subsurface safety valve 170. The production tubing 20 then extends below the subsurface safety valve 170 to the production zone. The production tubing 20 includes an electrical submersible pump 100 disposed at its lower end. The pump 100 is being reciprocated by a submersible, rotary electrical motor 110. Preferably, the motor 110 is disposed below the pump 100 so that formation fluids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com