Locking coupler for floor maintenance pad

a technology for locking couplers and floor maintenance, which is applied in the direction of carpet cleaners, instruments, photosensible materials, etc., can solve the problems of inability to provide reliable coupling and difficulty in releasing the retainer from the base, so as to achieve easy separation, easy removal, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

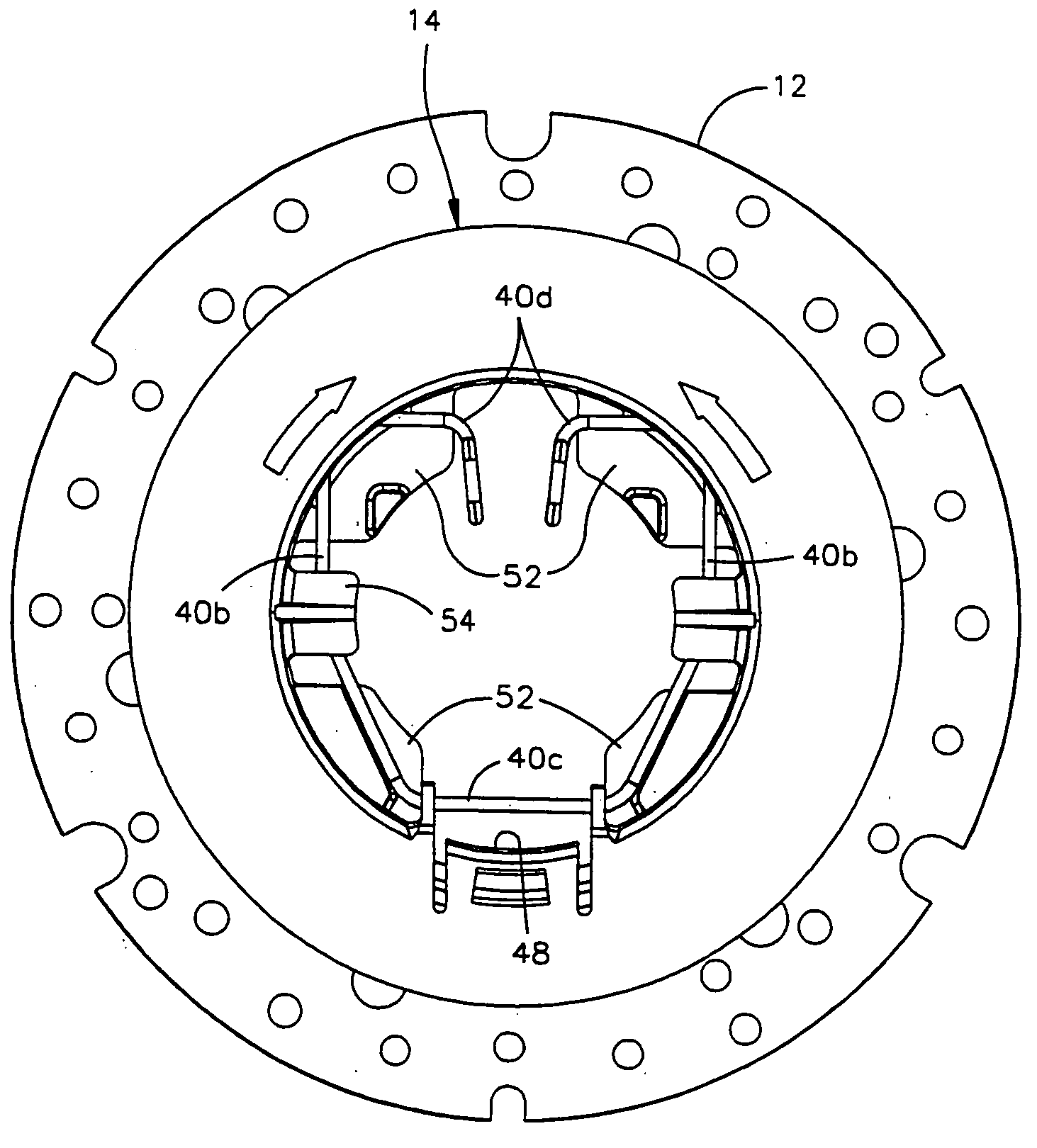

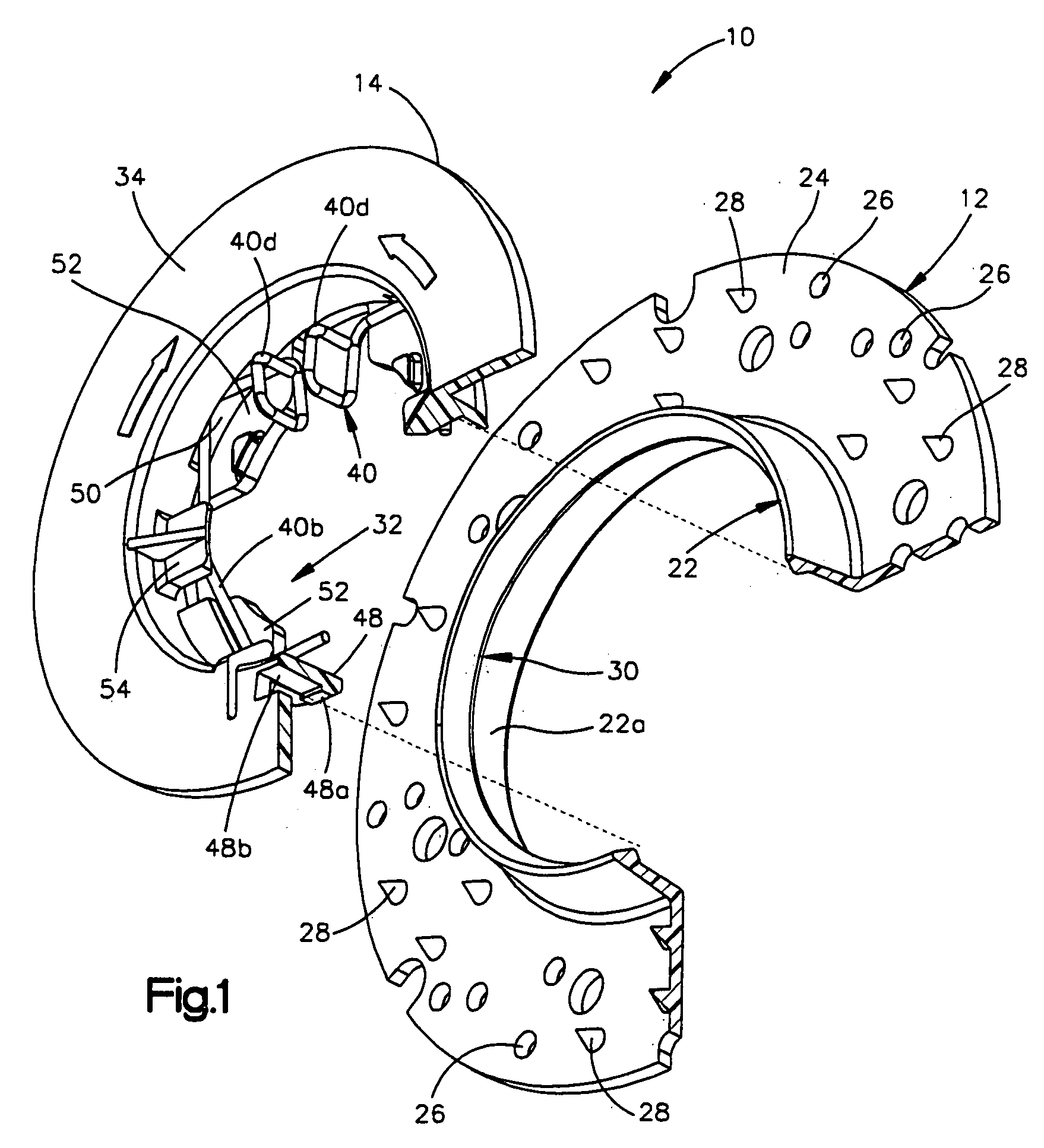

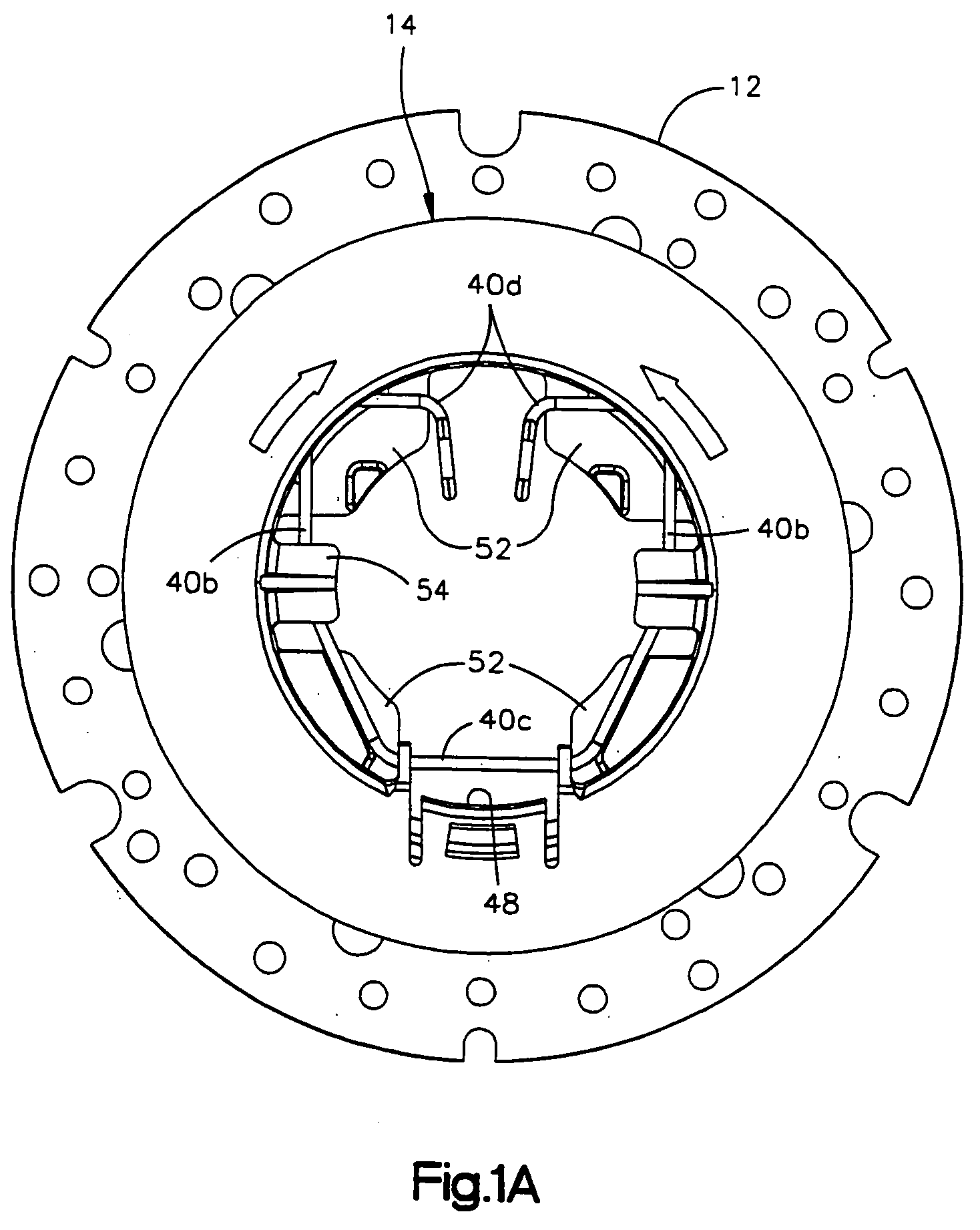

[0026]Referring to FIG. 1, a pad coupler 10 for a floor maintenance machine is shown which has a base 12 and a retainer 14. As seen in FIG. 2, the base 12 is coaxially attached to a pad driver disc 16. A portion of the retainer 14 extends through a circular mounting hole 18 of a floor maintenance pad 20 and, as will be de-scribed, “snaps” onto the base 12. The coupler 10 centers and holds the pad 20 to the disc 16 when in its coupled state.

[0027]In the machine illustrated in FIG. 2, the pad driver 16 engages the upper surface of the pad 20 with a plurality of bristles which operate to drivingly engage the pad for a variety of floor maintenance operations such as polishing, burnishing, scrubbing and stripping. Each separate task requires a pad 20 with particular abrasive characteristics. Due to the “snap together” feature of the disclosed pad coupler, the retainer 14 is readily uncoupled from the base 12 to permit an operator to replace the pad 20.

[0028]The base 12 is preferably mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com