Optical fibers for high power applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

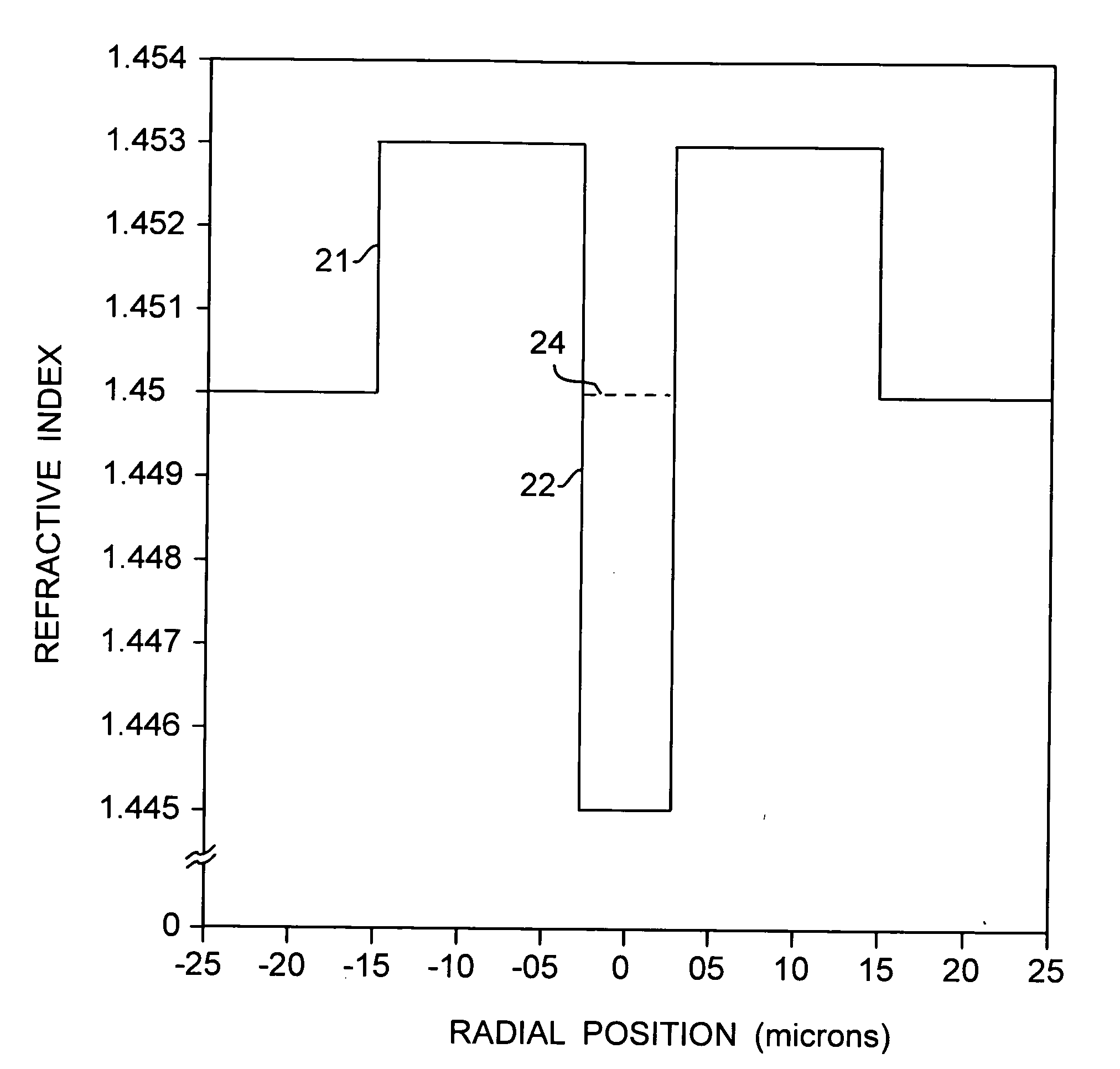

[0012]FIG. 1 shows a refractive index profile 11 for a conventional large mode area step index fiber. The plot is refractive index vs. radial position, and is idealized for the purpose of the description and analysis presented here. The core is typically Ge doped to an index value of approximately 1.452. The cladding shown here is pure silica with a nominal index of 1.45. The focus of these figures and this discussion is the core of the optical fiber. A wide variety of cladding structures, having un-doped layers, down-doped trench layers, up-doped layers for microbending control etc. may be used with the core structures described here.

[0013]FIG. 1 shows a large core, approximately 40 microns in diameter (with a fundamental LP01 modal effective area of approximately 750 μm2 around 1 μm wavelength). The large core serves to spread the modefield of the optical pulse and maintain the intensity below the threshold for damage.

[0014]However, as discussed above, even large core fibers like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com