Portable articulating tool support

a technology of articulating tools and supports, which is applied in the direction of machine supports, manufacturing tools, portable drilling machines, etc., can solve the problems of operator hands and arms, difficult to precisely manipulate tools, and large torque, and achieve the effect of improving the ease of use of hand-operated power tools and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

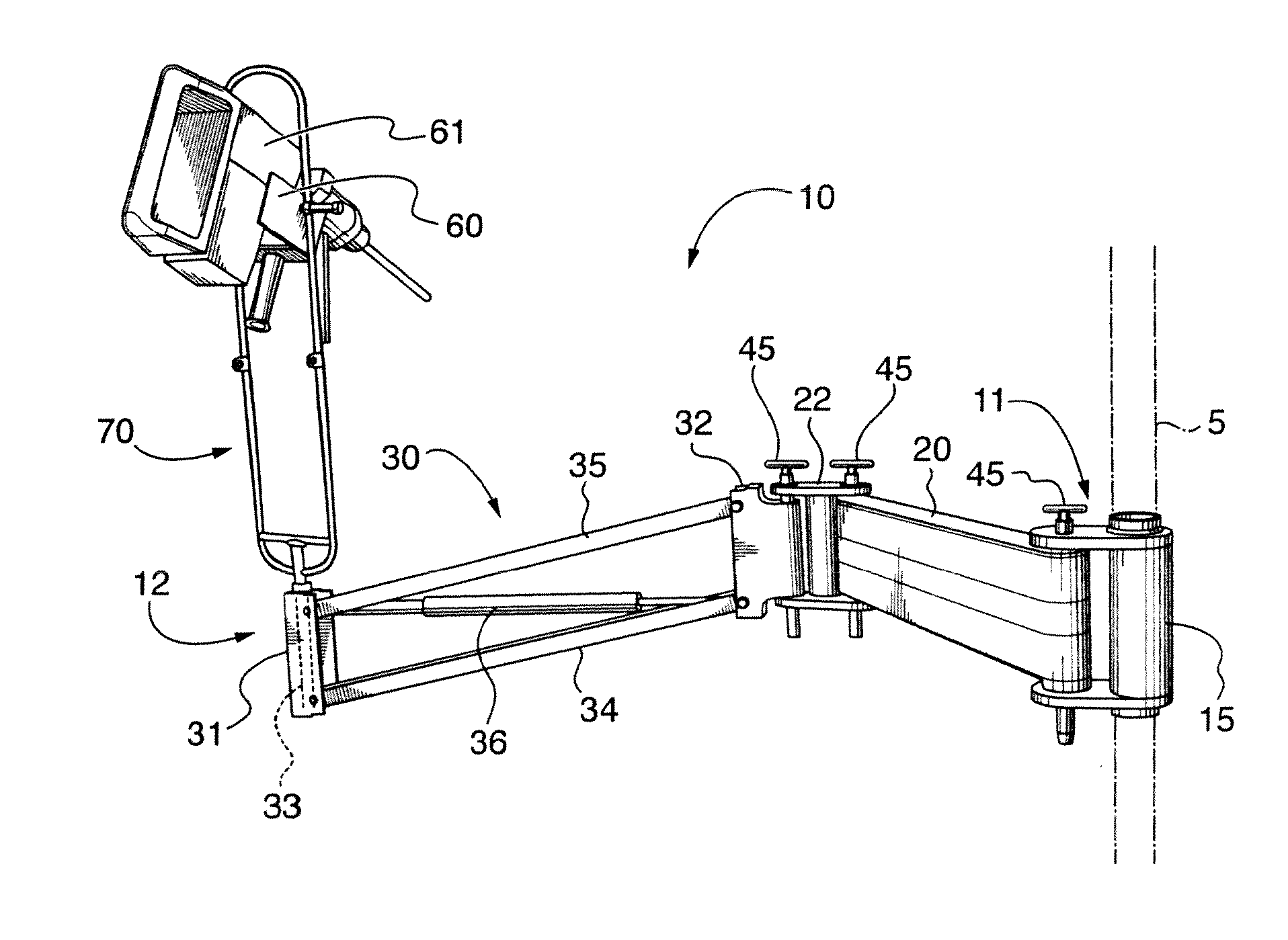

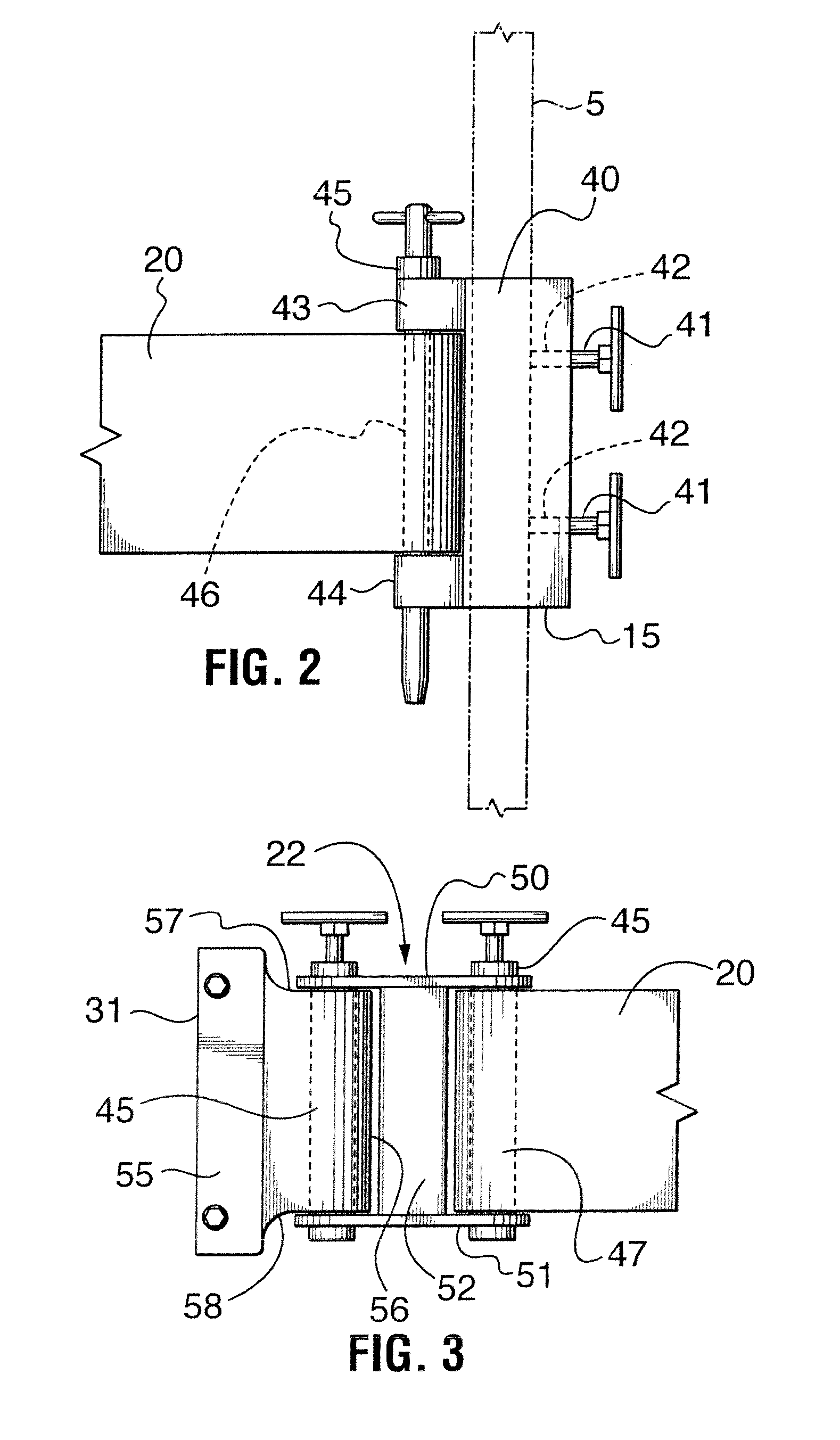

[0030] As shown in FIG. 1 of the accompanying drawings, a preferred embodiment of the present invention comprises a portable, multi-component articulating support apparatus 10 for a hand-manipulated power tool 61, e.g. a rock drill as shown. The support 10 has a proximal end 11 and a distal end 12, and is equipped with a mounting device 15 for detachable engagement with a support element 5 at proximal end 11. Mounting device 15 is detachably coupled to the proximal end of an elongated spacer element 20 by means of a hinge pin 45, while the distal end of spacer element 20 is detachably coupled to one side of double-axis hinge element 22 by means of another hinge pin 45. The distal end 12 of support apparatus 10 includes an articulating elongated counterbalance element 30 detachably coupled to the other side of double-axis hinge element 22 by means of another hinge pin 45. Articulating counterbalance element 30 has a distal bracket 31 and a proximal bracket 32, both pivotably connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weights | aaaaa | aaaaa |

| weights | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com