Roller Assembly

a technology of rollers and assemblies, which is applied in the direction of multi-purpose tools, door/window fittings, construction, etc., can solve the problems of frequent replacement of parts, significant wear and tear of rollers of doors, and the need for frequent maintenance of doors, so as to achieve cost-effective production, operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

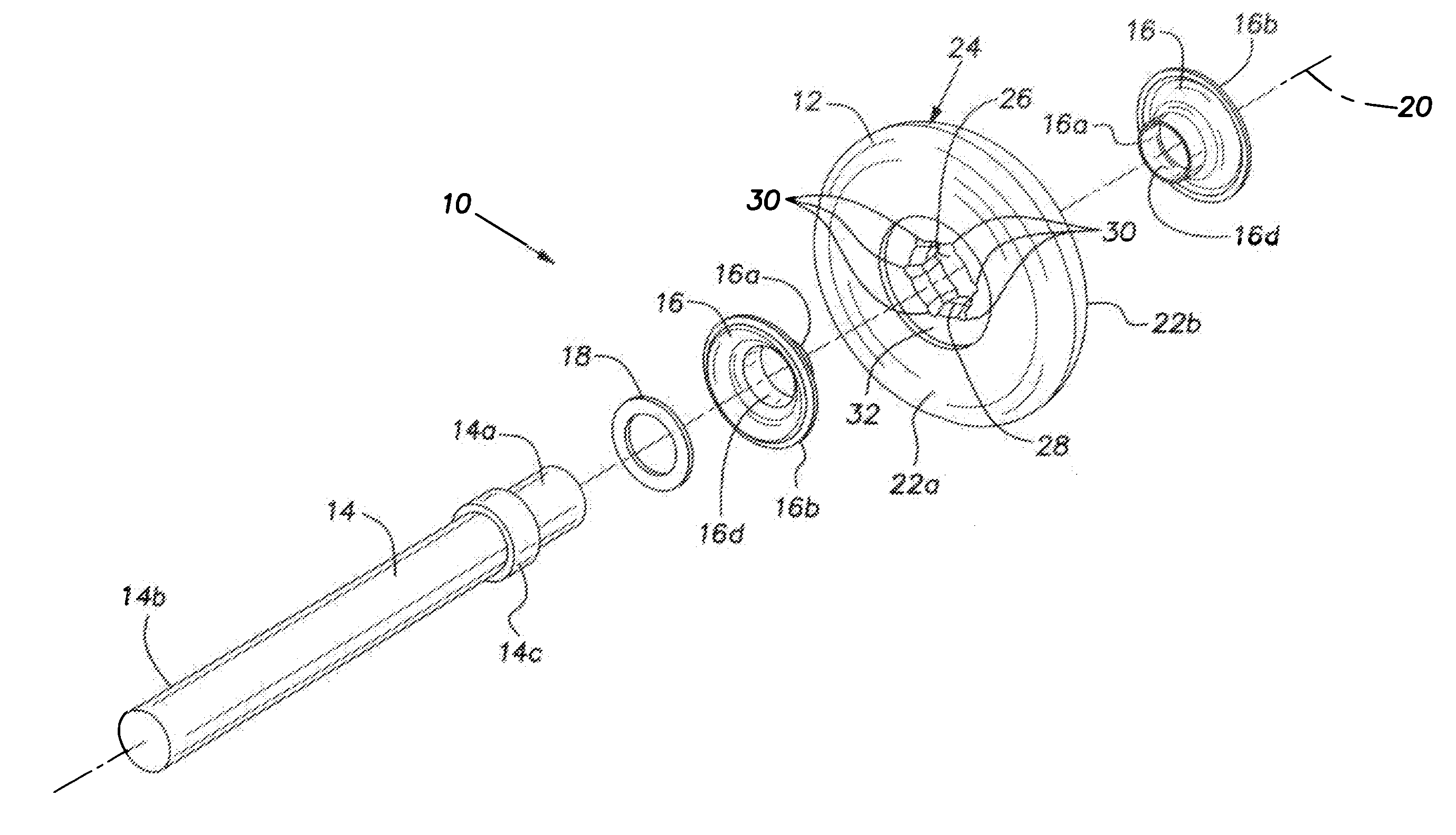

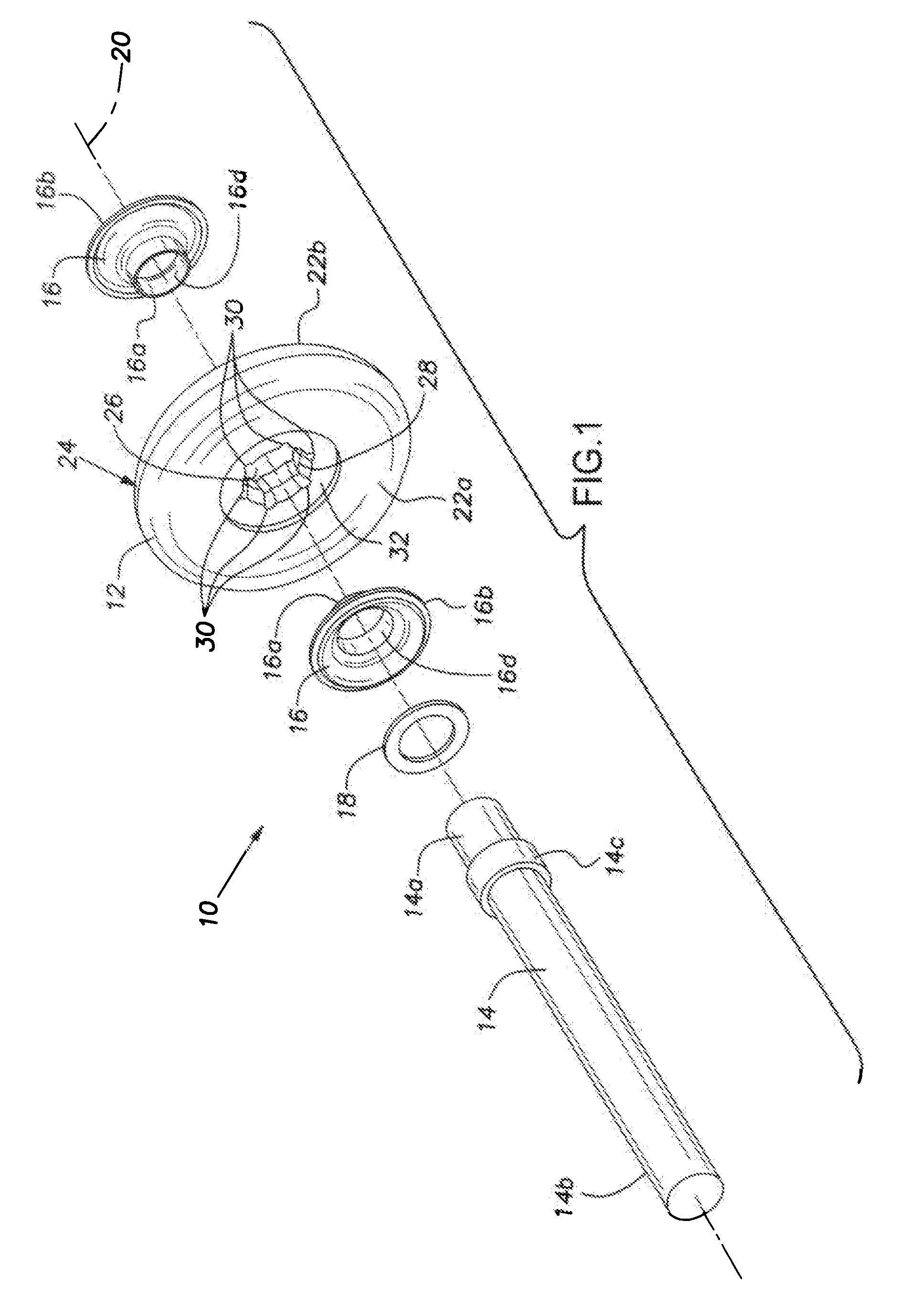

[0022]FIG. 1 shows an exploded perspective view of one embodiment of a roller assembly 10 of the present invention. The roller assembly 10 basically comprises a roller 12, a shaft 14, and one or more ferrules 16. Preferably, as shown in FIG. 1, there are two ferrules 16. Also, in the preferred embodiments, a washer 18 is part of the roller assembly 10. All of these parts are assembled along an axis 20 so as to allow the roller 12 to rotate around the axis 20. The roller assembly 10 of the present invention is especially well suited for use in a flexible over head door such as a garage door or a rolling over head door on a commercial truck.

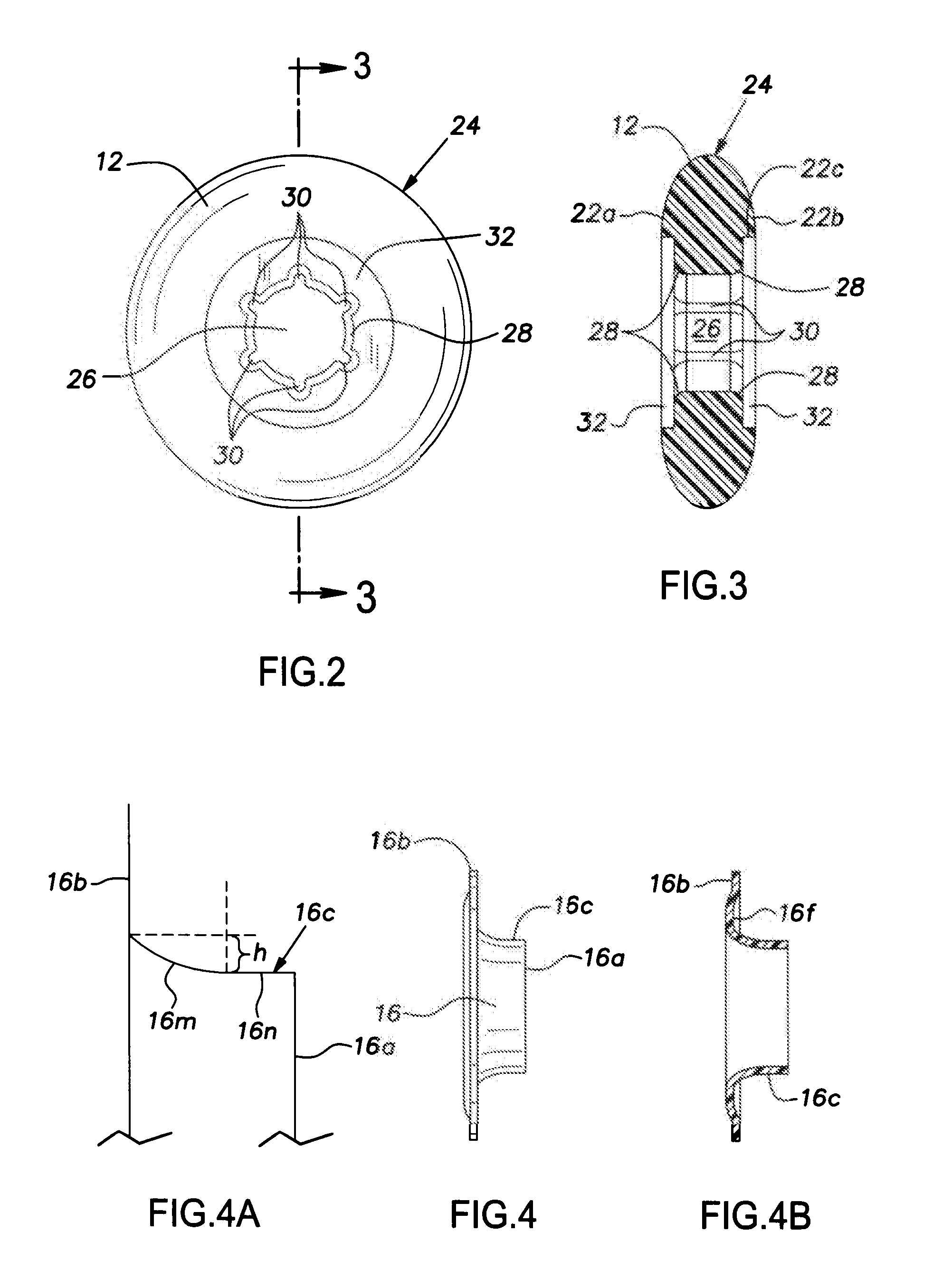

[0023]As can be seen, for example, in FIGS. 1-3, the roller 12 has first and second sides 22a and 22b, a rolling surface 24, and an interior bore 26 extending through the roller 12 and centered along the axis 20. The diameter of the interior bore 26 allows the shaft 14 to fit within the bore, as will be explained further herein. The rolling surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com