Diaphragm pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

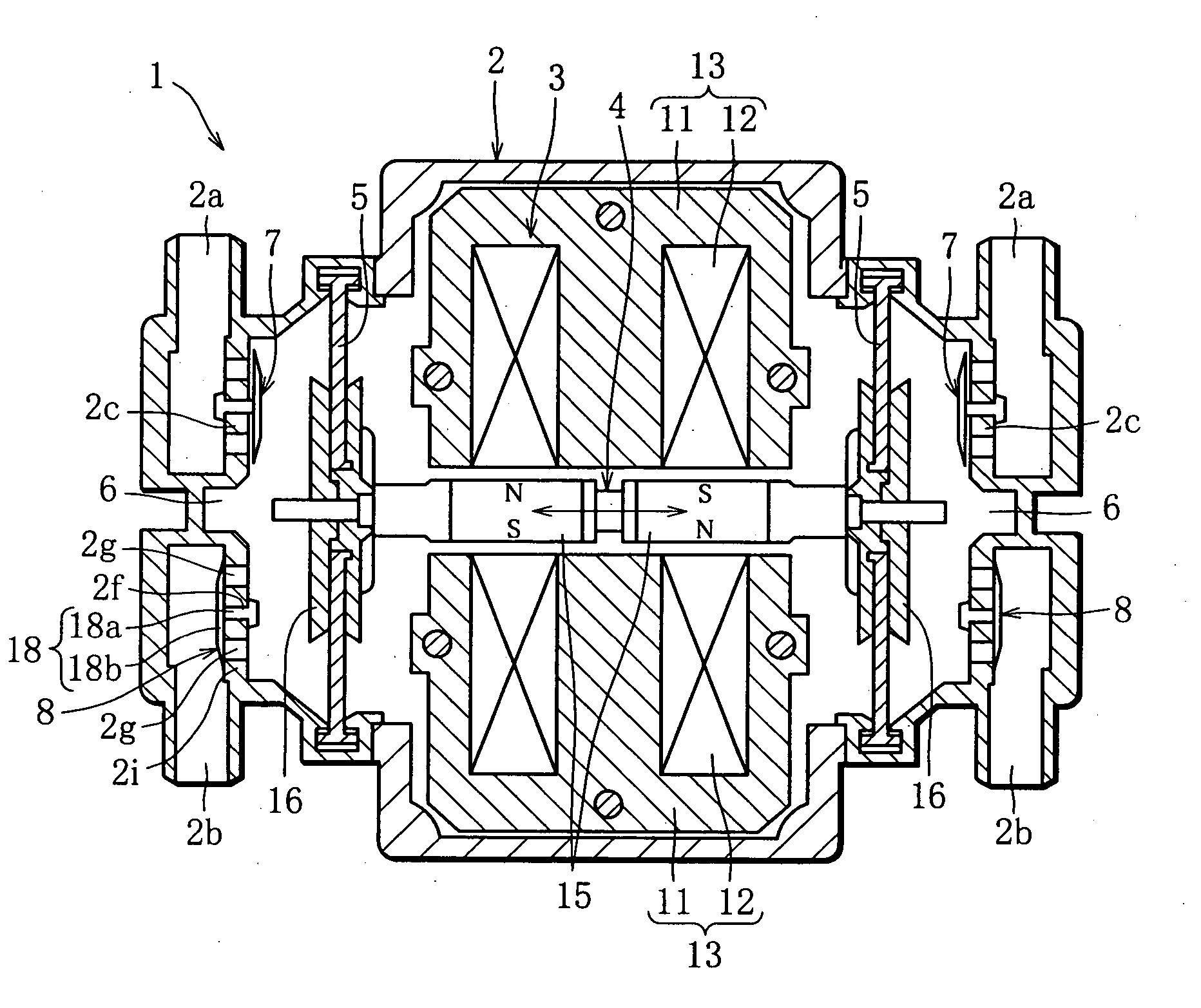

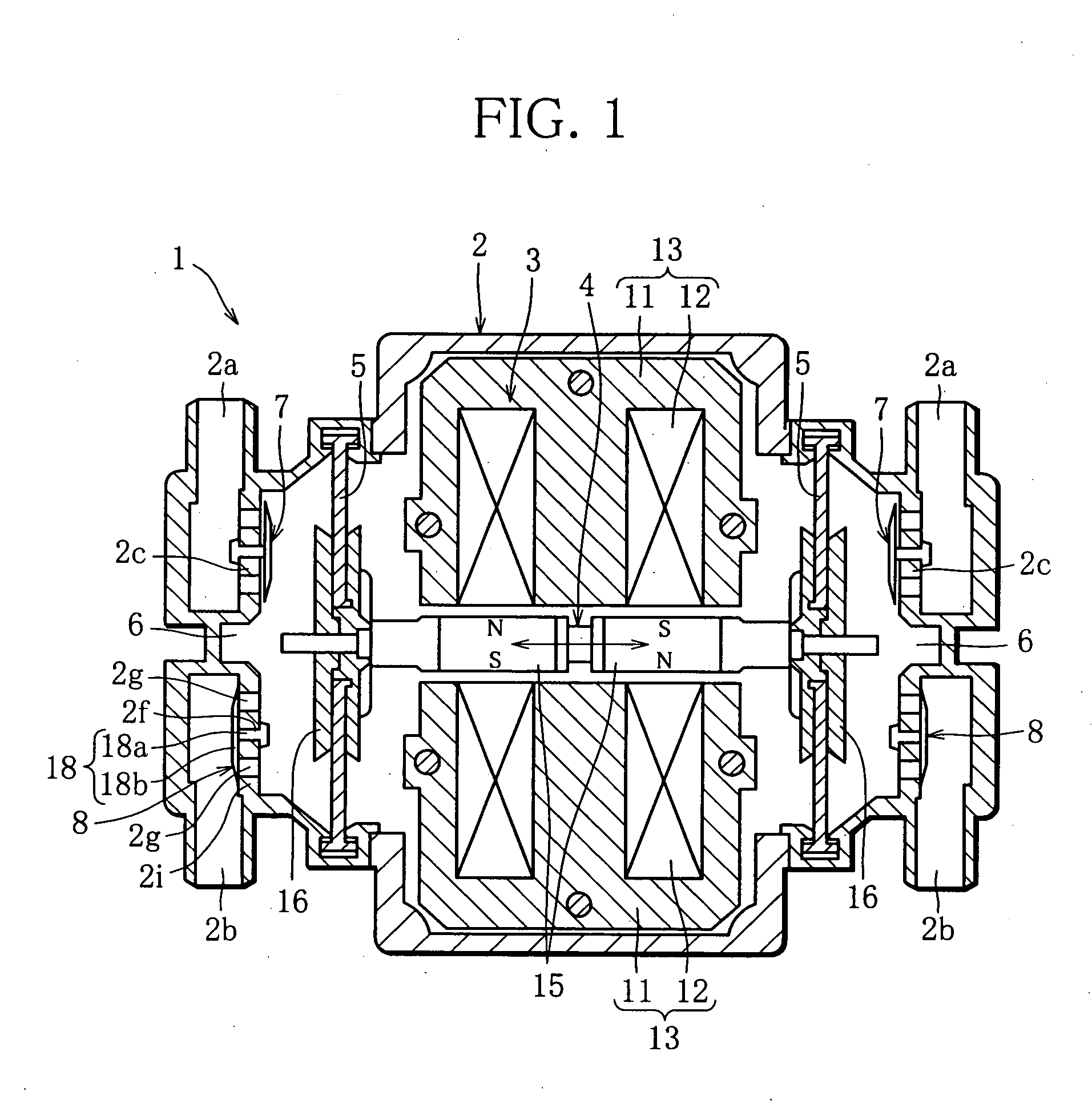

[0023] Referring to the drawings, an embodiment of this invention will be described, using an example of an electromagnetic diaphragm pump which is driven by an electromagnet to compress and discharge air.

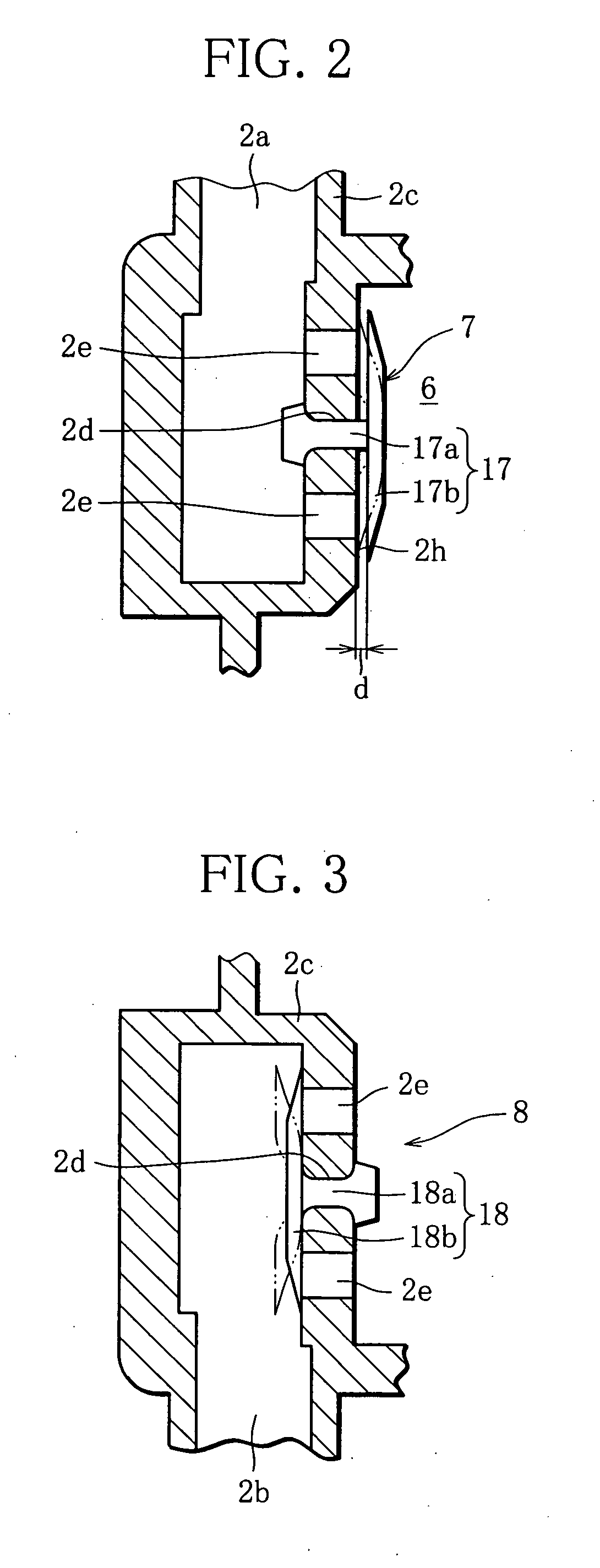

[0024]FIG. 1 is a cross-sectional view schematically showing the structure of an electromagnetic diaphragm pump in an embodiment of this invention. The electromagnetic diaphragm pump 1 comprises a frame 2, an electromagnet 3 enclosed in the frame 2, a rod-like oscillator 4 driven by the electromagnet 3 to move back and forth in the axial direction, two diaphragms 5, 5 provided at the opposite ends of the oscillator 4, and paired pressure chambers 6, 6 provided outside the frame 2, each having one of the diaphragms 5, 5 as a wall. As described later, the paired pressure chambers 6, 6 are formed by paired casings 2c, 2c which are fitted to the frame 2 on both sides, in a manner covering each diaphragm 5.

[0025] Each casing 2c has a suction port 2a and a discharge port 2b each connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com