Fixed Weight Dumbbell Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

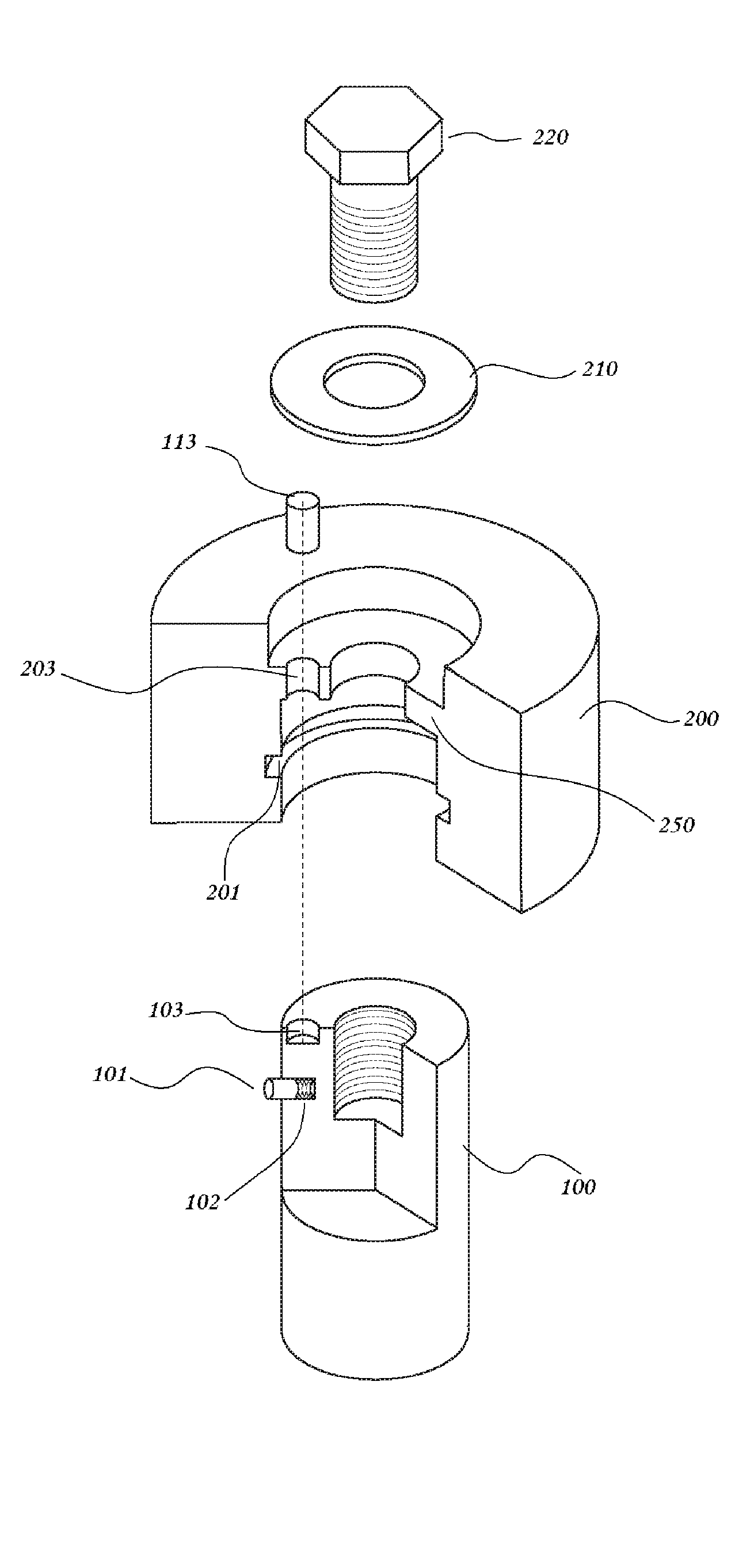

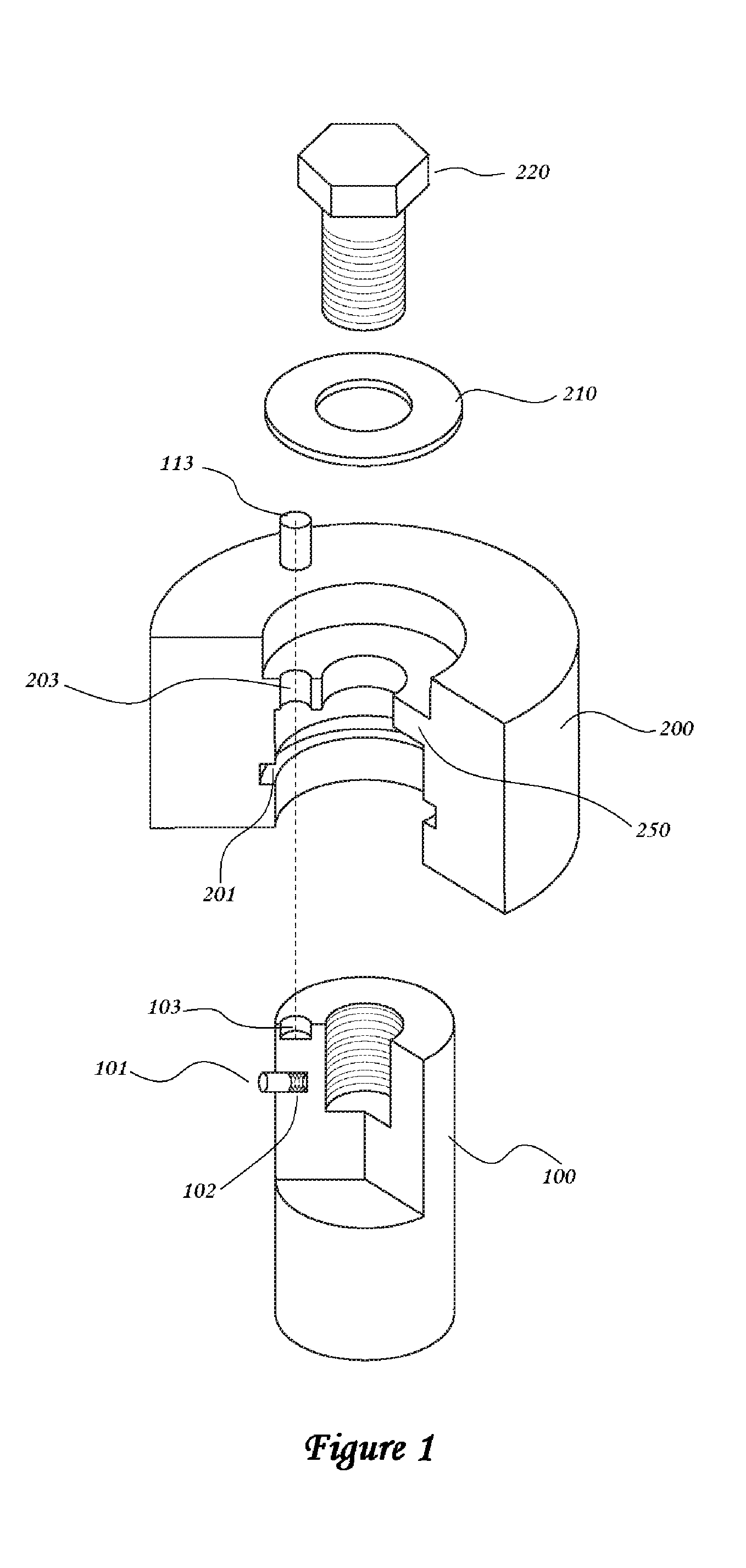

[0011] In FIG. 1, a handle bar 100 contains a spring pin 101 and a spring 102 in a hole near one end of said handle bar. On the opposite end of the handle bar 100, identical construction of present invention needs no further explanation.

[0012] Spring 102 is so situated in the hole to provide resilience force for spring pin 102 to move in radial direction of the handle bar 100's axis.

[0013] At end of handle bar 100, a lock pin 113 is movably situated in a position hole 103 axially dug in to the cut off end of said handle bar 100.

[0014] Said handle bar 100 further has an axial length of drilled opening from each cut-off end containing thread lines on the inside wall.

[0015] On weight head 200, a ring of shoulder 250 is formed in its center through bore. Said shoulder 250 divides the center through bore into a first side and a second side. Said first side is to snuggly receive said handle bar 100. Said second side is to receive a washer piece 210 and a lock nut 220.

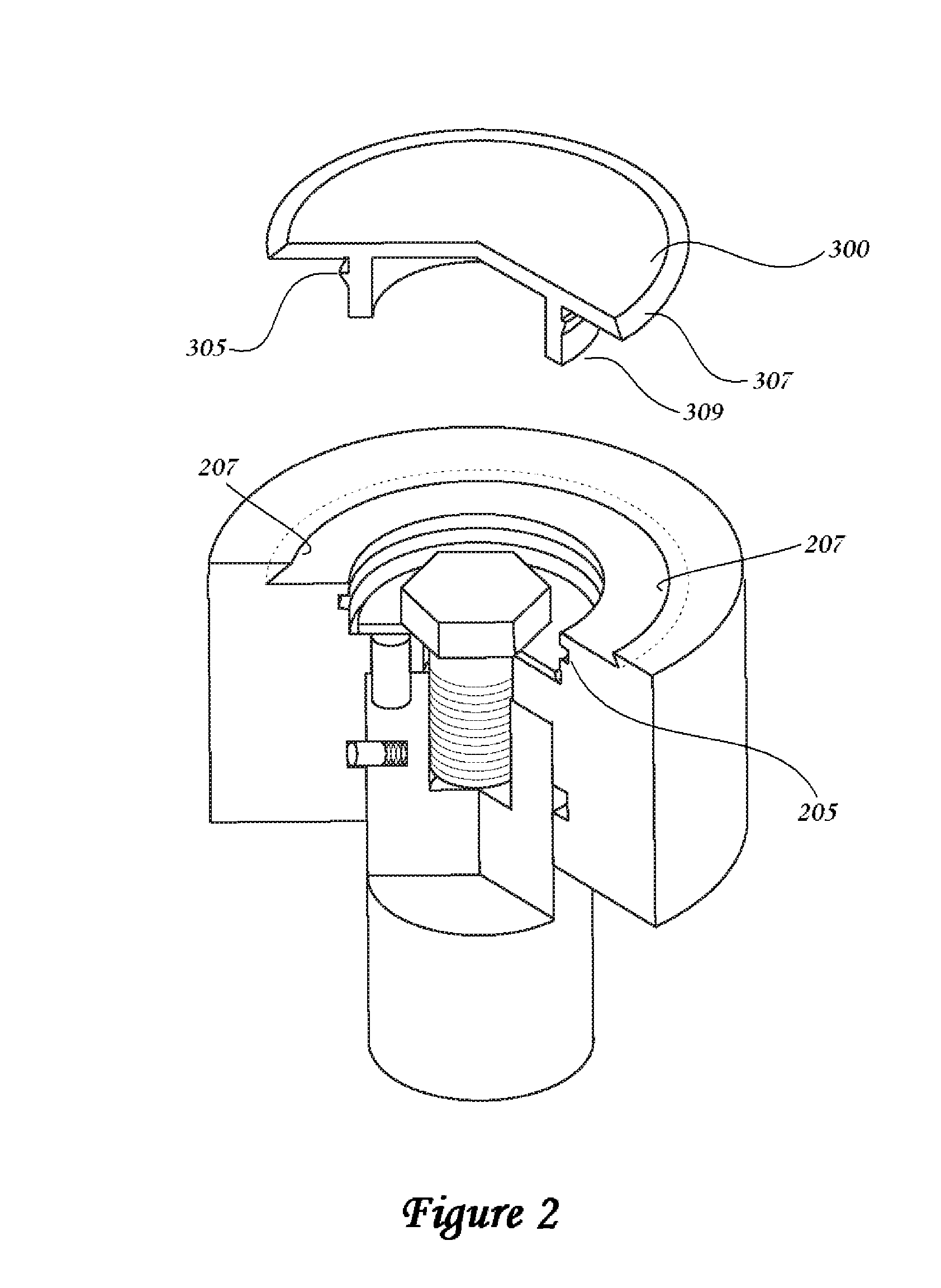

[0016] A locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com