Water heating systems and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

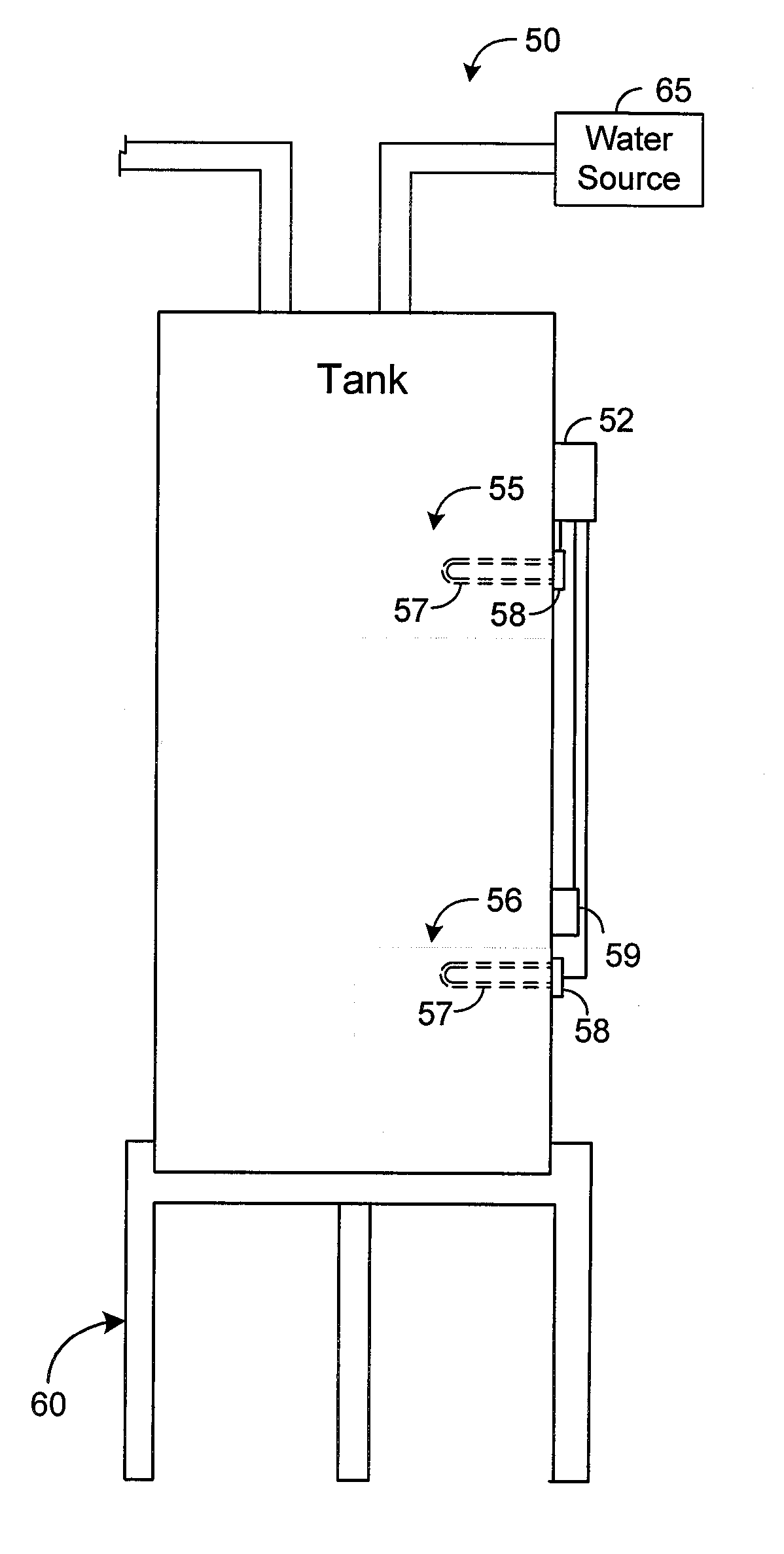

[0045]FIG. 1 depicts a water heating system 50 in accordance with an exemplary embodiment of the present disclosure. In this regard, FIG. 1 depicts an exemplary water heater controller 52 that is electronically actuated and is mounted on a side of a tank 53, although the water heater controller 52 may be positioned at other locations in other embodiments. The system 50 shown by FIG. 1 has two heating elements, referred to as “upper heating element 55” and “lower heating element 56.” Each heating element 55 and 56 comprises an electrically resistive coil 57 that, when activated, emits heat to water or other fluid within the tank 53 and a base 58 that is mounted to a side of the tank 53. The coil 57 is located within the tank 53 and is submerged in the water held by the tank 53. Any known or future-developed heating element may be used to implement either of the heating elements 55 or 56. For many conventional heating elements, the base 58 is screwed into the tank 53 through a hole in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com