Offset valve system for downhole drillable equipment

a valve system and drillable technology, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of difficult to prevent the valve mechanism from spinning, large problems, and unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

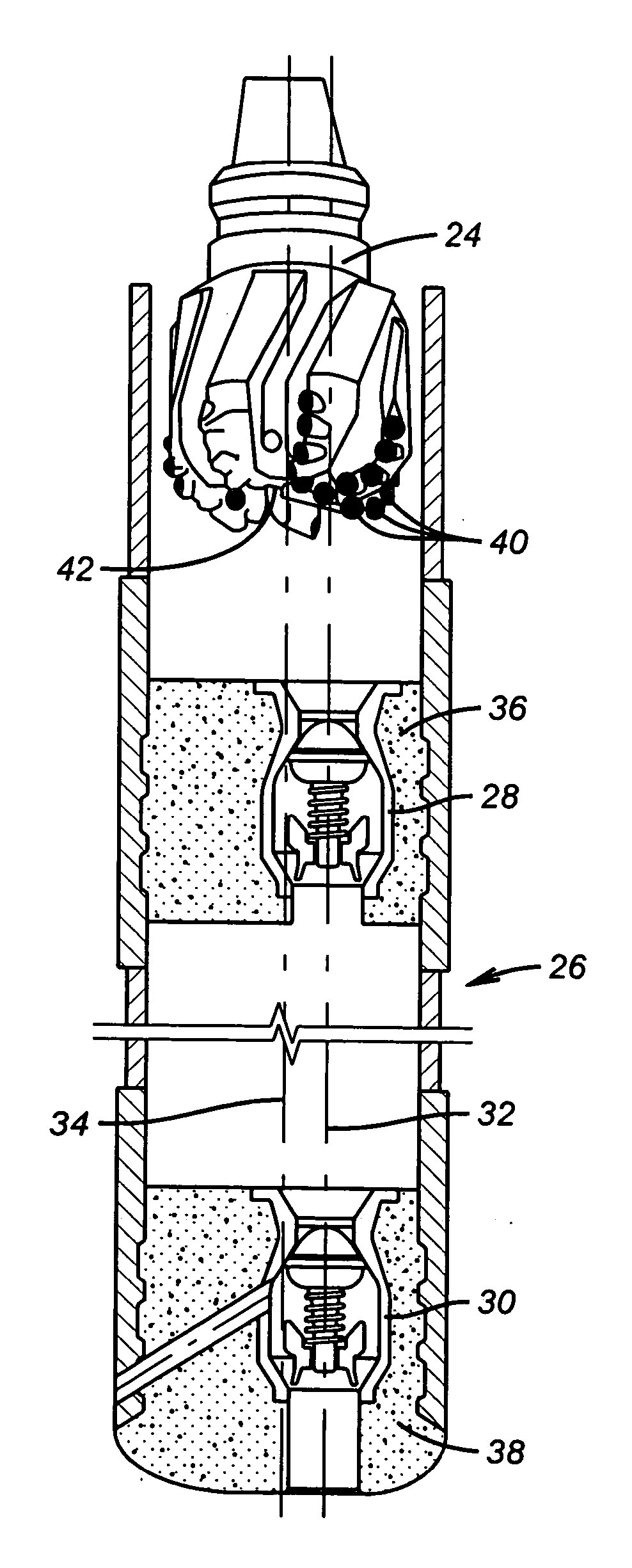

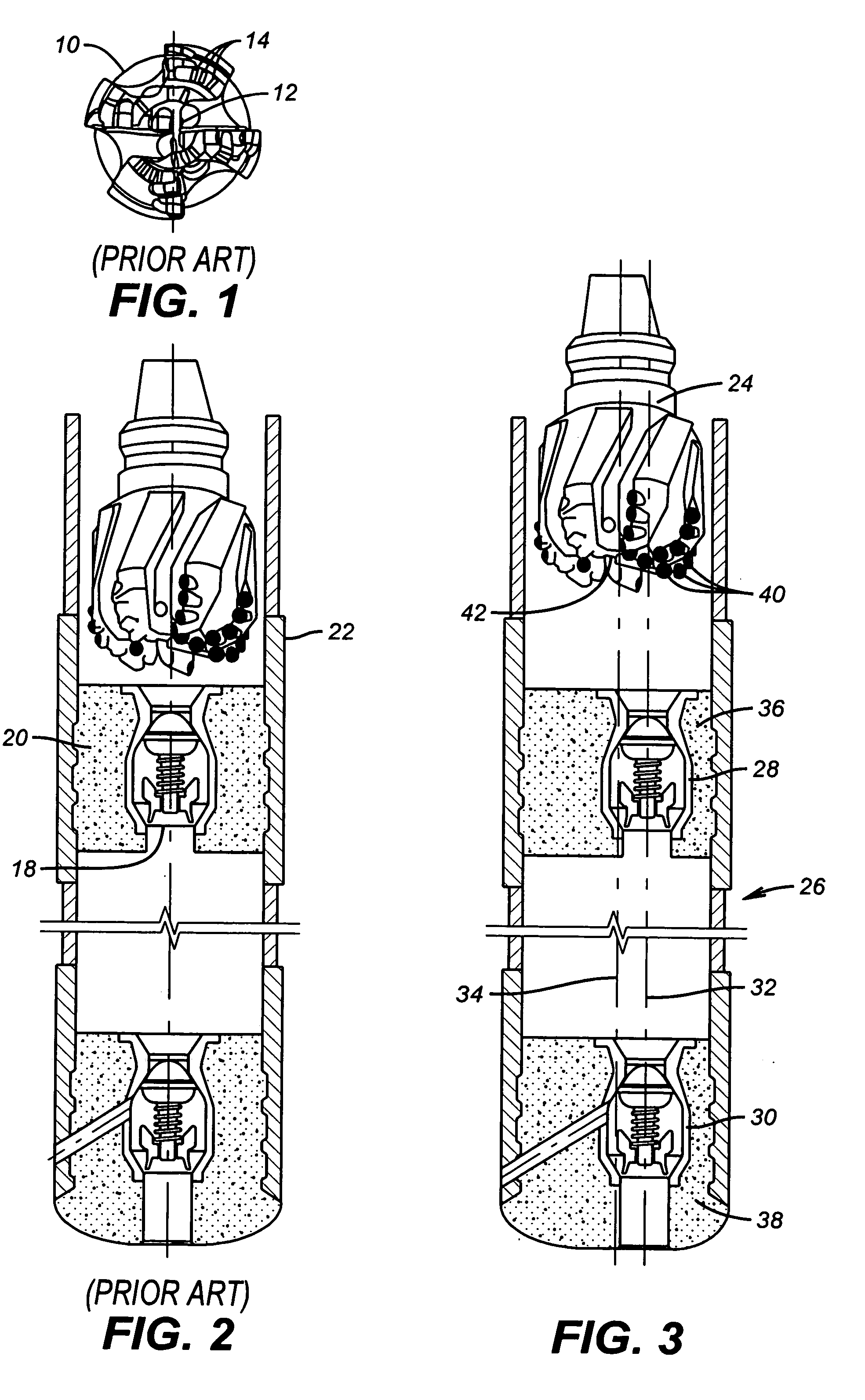

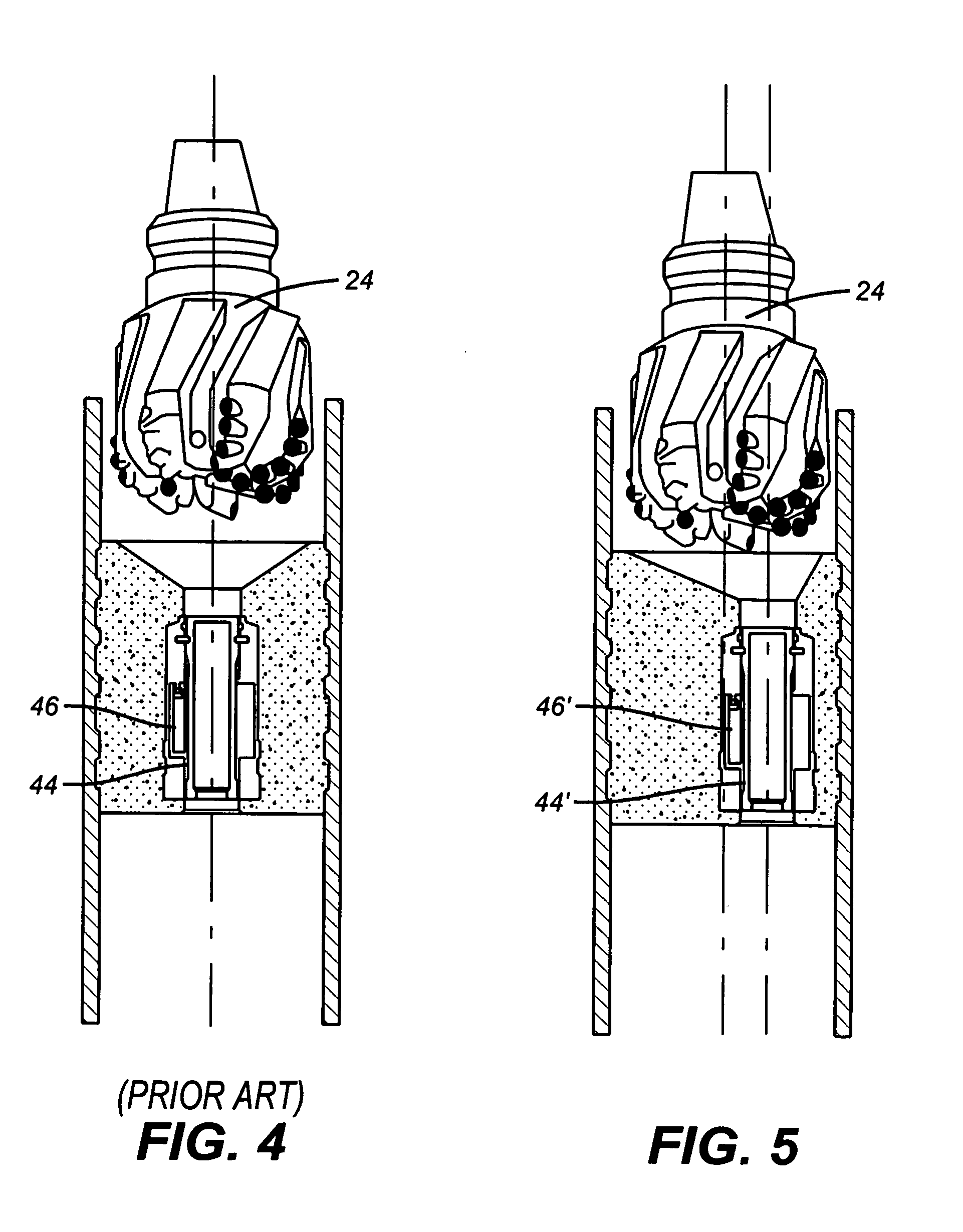

[0020]FIG. 3 shows a bit 24 just above a shoe track 26 which comprises poppet type valves 28 in a float collar and 30 in a float shoe of a typical shoe track 32 which is offset from centerline 34 of the shoe 26. Valves 28 and 30 can also be on different centerlines from each other while both are offset radially from the centerline 34 of the shoe 26. Cement (or any type of drillable material) 36 and 38 respectively surrounds valves 28 and 30 for support in the shoe track 26. As an alternate to cement, other common drillable materials used in the oil industry can be used.

[0021] The bit 24 has bottom details similar to those shown in FIG. 1. It can be a polycrystalline diamond bit, a rock bit or a tapered or flat bottom mill.

[0022] Because the valves 28 and 30 are offset from centerline 34 the inserts 40 dig directly at the valve assemblies as opposed to having the nozzles 42 that are generally in the center of the bit align with valves 28 and 30 which makes them harder to mill out. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com