Composite materials and devices comprising single crystal silicon carbide heated by electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Example 1

Heating of A Low-Loss Dielectric Fluid

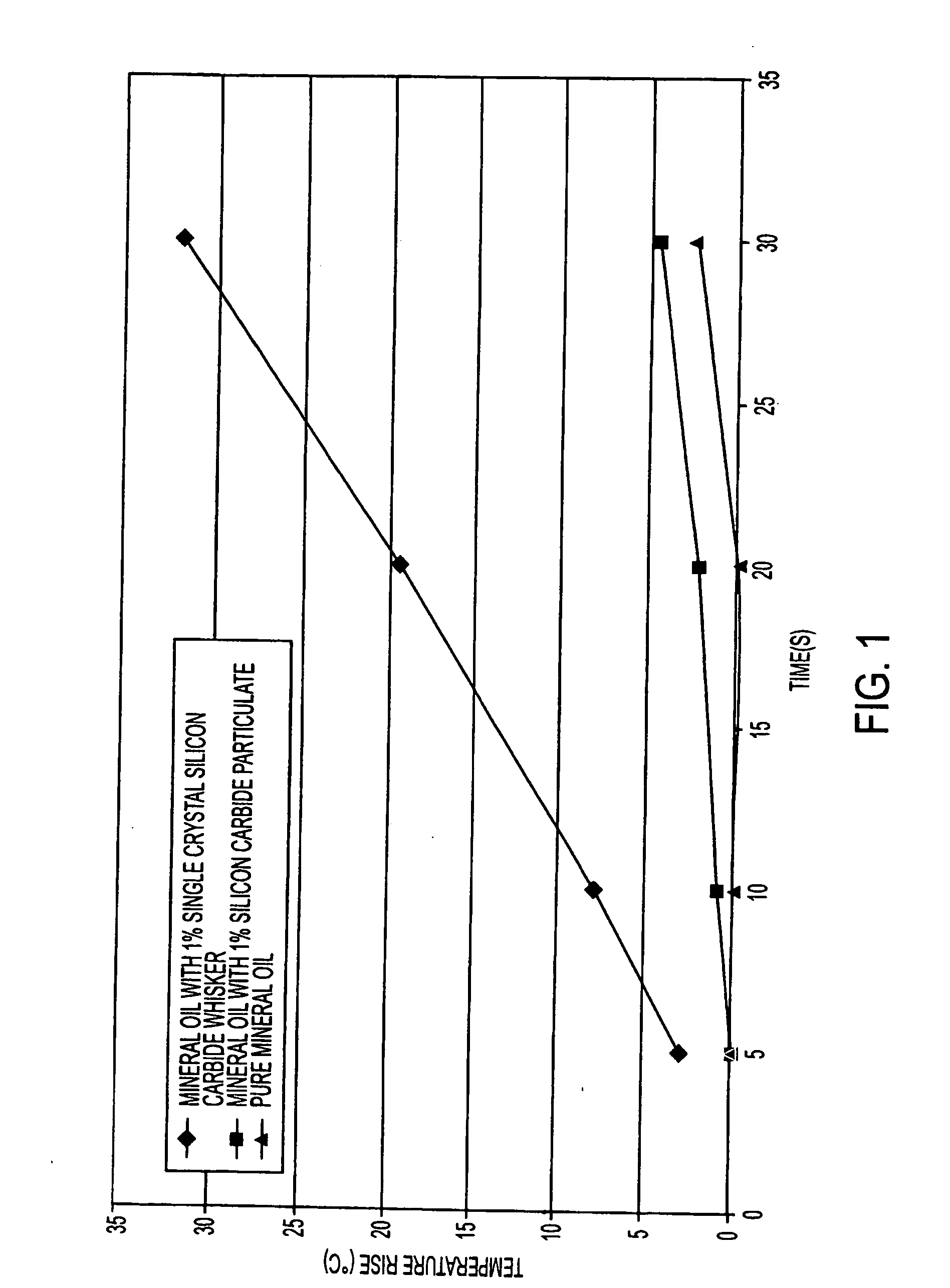

[0076] Refined mineral oil of 100% hydrocarbon (paraffin oil) content has a low dielectric loss when subjected to electromagnetic radiation, including microwave radiation. Therefore, it does not heat when exposed to microwave radiation. Single crystal silicon carbide whiskers (0.6 micron average diameter, 9 micron length) and ultrafine silicon carbide particulate (TABLE 1Temperature Increase, ° C.Mineral Oil (1%Mineral Oil (1%PureTime,Single CrystalSilicon CarbideMineralsecondsSilicon Carbide)Particulate)Oil53.000108.01.002019.72.303032.34.72.7

[0077] As expected, pure mineral oil exhibits only a 2.7° C. temperature rise. Mineral oil with 1% silicon carbide particulate exhibits 4.7° C. temperature rise. Surprisingly, mineral oil with 1% by weight of single crystal silicon carbide whiskers exhibits a 32.3 ° C. temperature rise. The single crystal silicon carbide whiskers used in the invention were far superior to fine powder forms of si...

Example

Example 2

Heating of A Low-Loss Dielectric Fluid

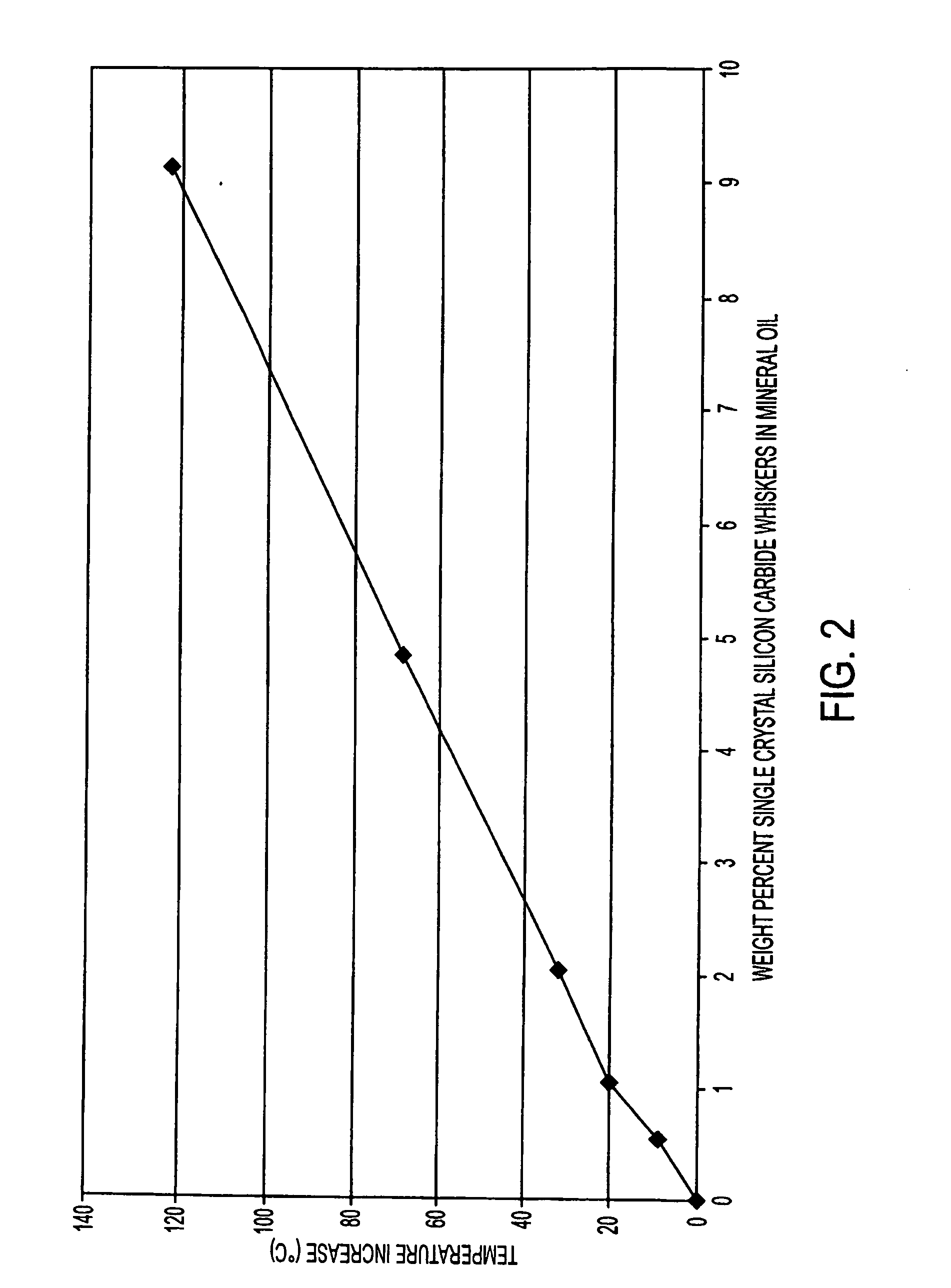

[0078] Single crystal silicon carbide whiskers used in the invention were again added to 100% paraffin mineral oil. In this example, the silicon carbide of the invention was added at increasing weight percentages, with the goal of increasing the dielectric loss tangent with increasing weight percent single crystal silicon carbide whiskers. Each sample was separately subjected to a microwave-energy field of 2.45 GHz at 1000 watts for 20 seconds. The temperature rise is shown in Table 2 below, and is illustrated in FIG. 2: TABLE 2Wt percent Single Crystal SiliconCarbide Whiskers In Mineral OilTemperature Increase, ° C.000.58.71.019.72.032.04.868.79.1122.3

[0079] As can be clearly seen from this data, increasing the concentration of single crystal silicon carbide whiskers accelerated the temperature increase. Thus, the dielectric loss tangent increased with increasing single crystal silicon carbide whisker concentration.

Example

Example 3

Heating of A Low Dielectric Solid

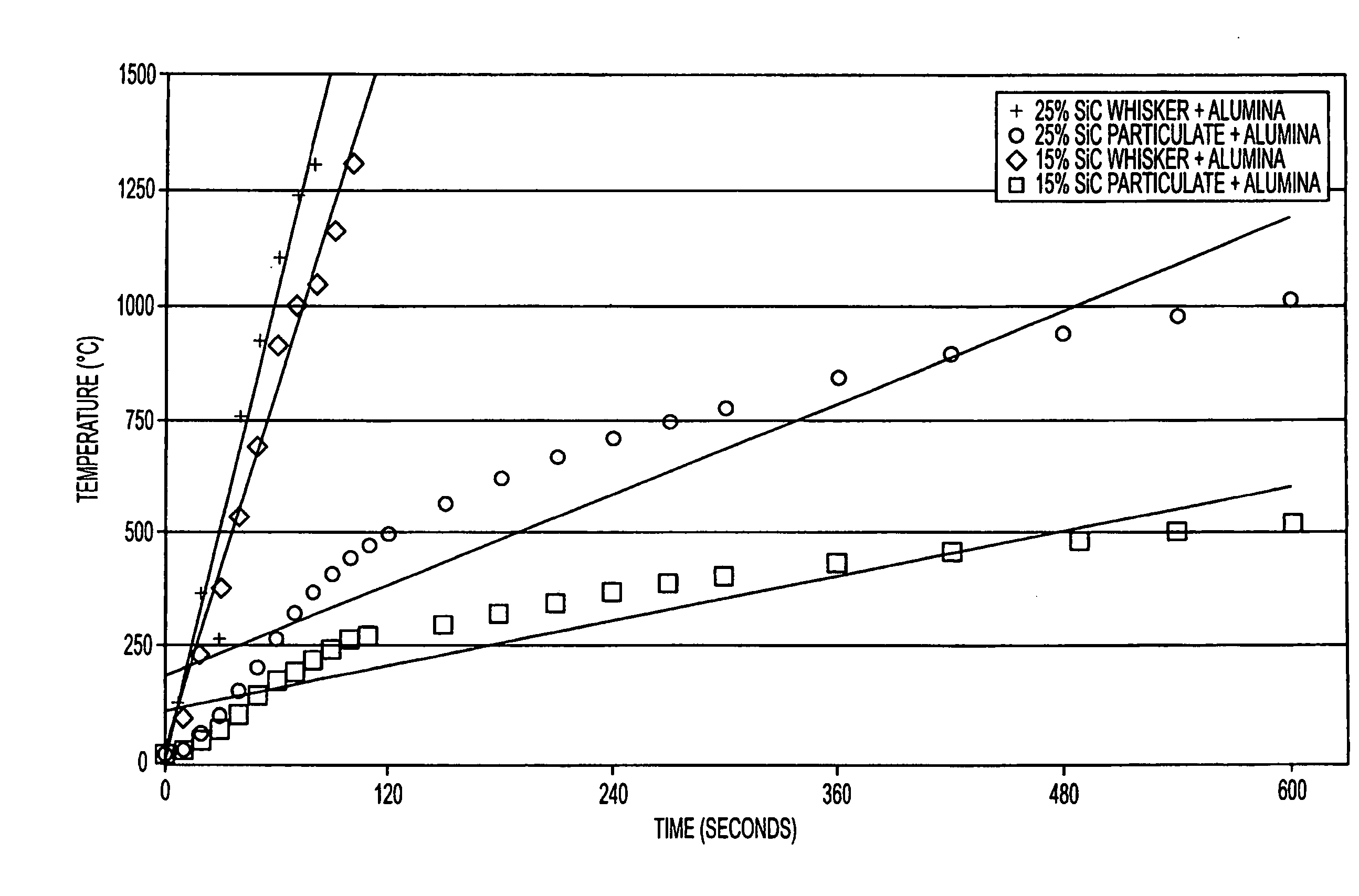

[0080] Alumina is a ceramic material that has a very low dielectric loss tangent in the RF and microwave spectra. Therefore, it does not efficiently convert this energy into heat. Ceramic composites (composite material of the invention) were made by combining alumina with the single crystal silicon carbide whiskers of Example 1. These composites were then hot-pressed into a ceramic composite material of the invention. This ceramic composite was subjected to a microwave field of 2.45 GHz at 1000 watts. The temperature of the ceramic was recorded with time. Results are shown in FIG. 3.

[0081] As can be clearly seen, single crystal silicon carbide whiskers formed composite materials of the invention with alumina and heated rapidly compared with the microwave-transparent matrix material (alumina), and the rate of temperature increase was made larger by a greater proportion, measured as wt percent, of single crystal silicon carbide whiskers in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com