Semi-enclosed applicator for distributing a substance onto a target surface

a technology of applicators and substances, applied in the direction of seal fixers, containers with multiple articles, packaging goods types, etc., can solve the problems of contamination of substances, unprotected substances, and loss of substances on surfaces,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

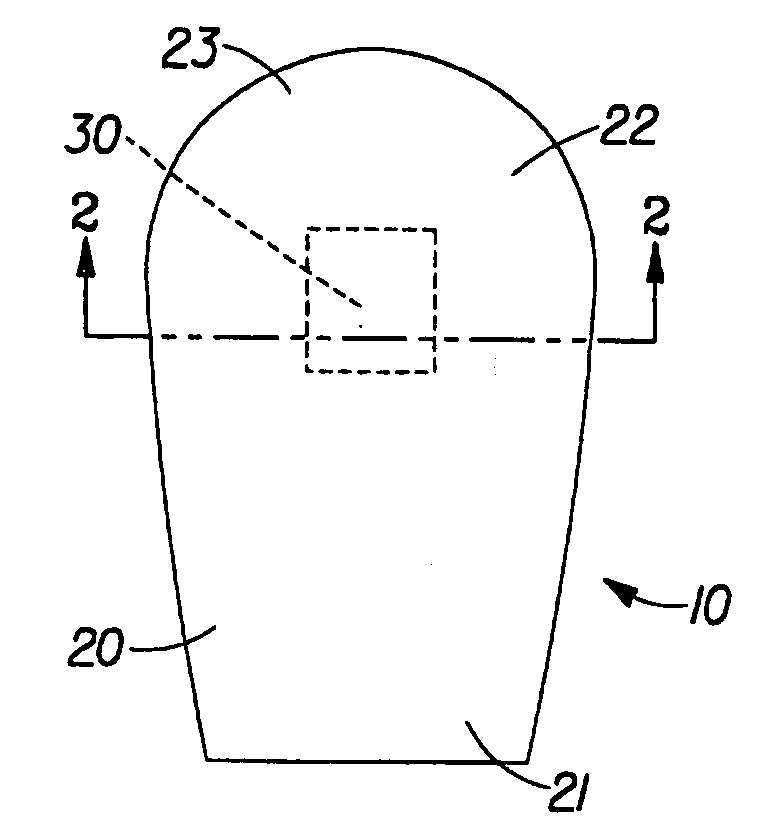

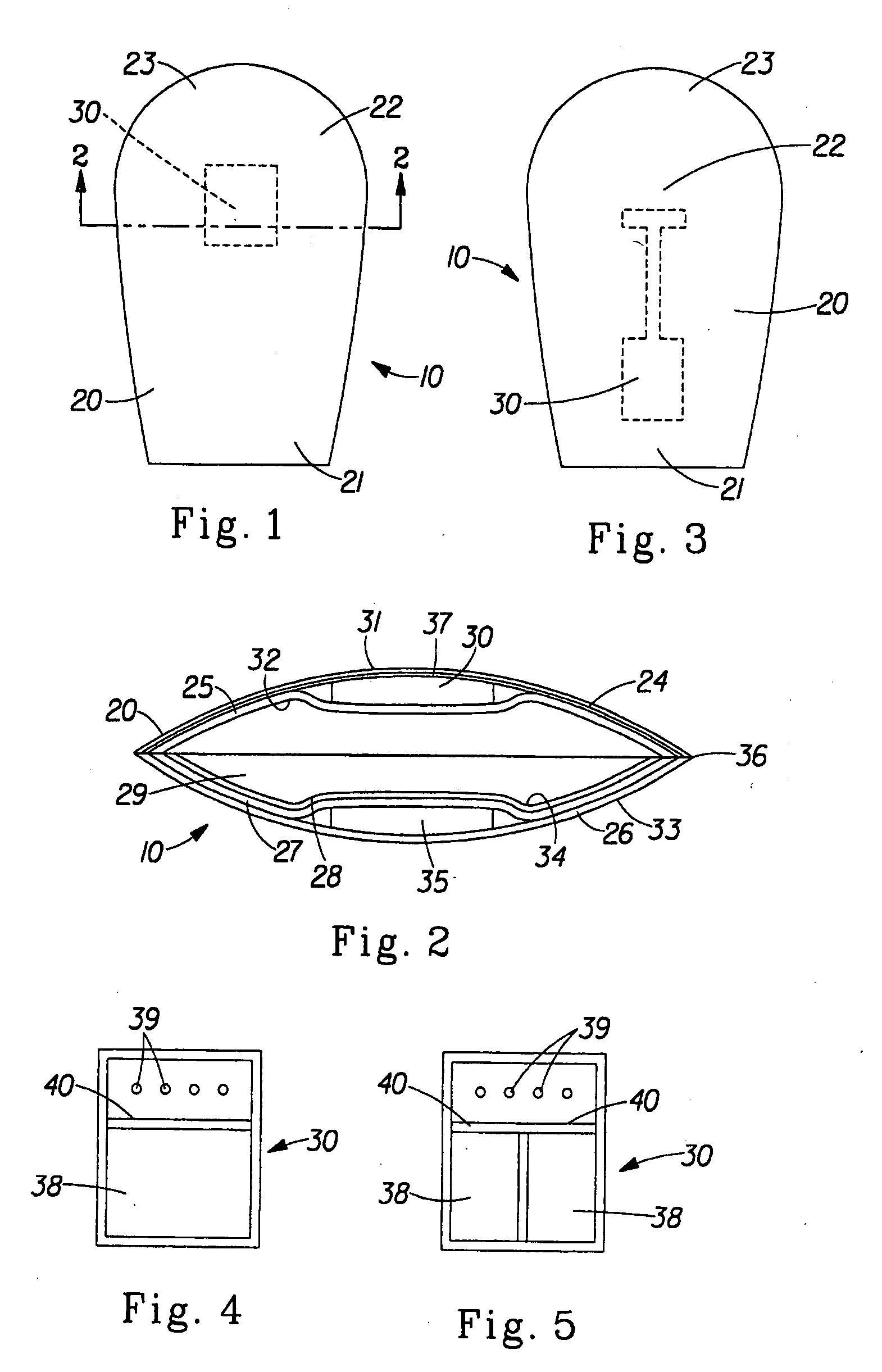

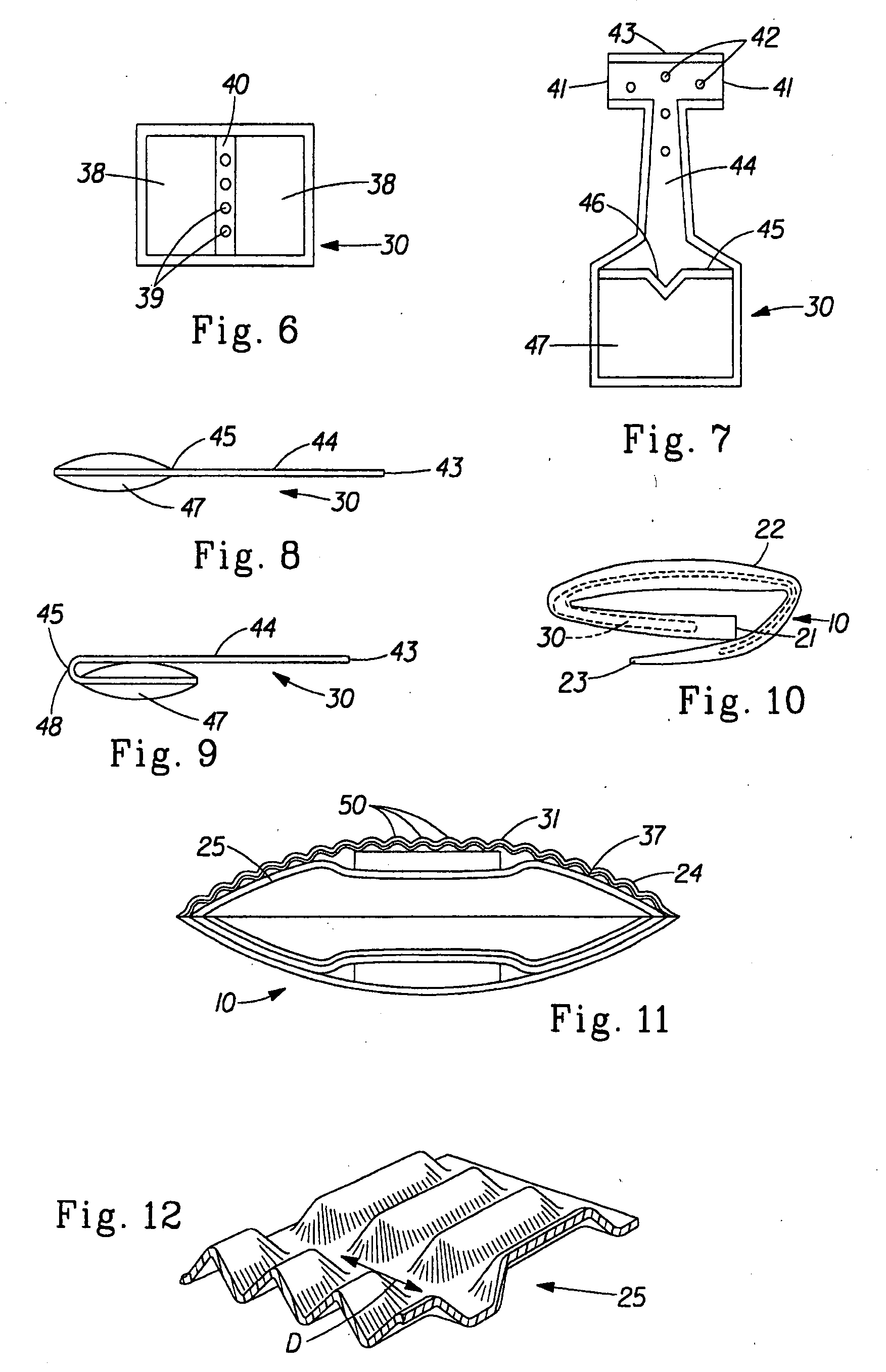

example 1

[0157] An applicator made in accordance with the present invention may include a glass cleaning mitt, such as described in detail in copending U.S. application Ser. No. ______ entitled “Semi-Enclosed Applicator for Distributing a Substance onto a Target Surface” and filed by Gruenbacher et al on Oct. 9, 2000 (P&G Case 8116M), which is incorporated by reference. The glass cleaning mitt can provide a flexible structure for distributing glass cleaning substance onto a target glass surface. Such an applicator might include a first fluid-containing reservoir having a predetermined amount (e.g., in the range from about 5 cc's to about 20 cc's) of a liquid cleaning product such the CINCH® brand product as available from The Procter & Gamble Company, Cincinnati, Ohio. The mitt itself may include a front panel layer comprising a polypropylene spunbonded nonwoven material to provide a substrate for spreading the cleaning substance and scrubbing the surface with the cleaning solution. For exam...

example 2

[0163] An applicator made in accordance with the present invention may include a personal care mitt. For example, these mitts may be used for the purpose of, but not limited to, beautifying (i.e., improving the visual appearance and / or feel), cleaning, moisturizing, conditioning, or otherwise treating the skin, hair, or nails. Product applications include, but are not limited to, face and body cleansers, toners, lotions, moisturizers, ointments, cosmetics / make-ups, medicaments, and related topically applied treatments.

[0164] As shown in FIG. 58, for example, a two-finger mitt 558 for applying a heated moisturizer to the face may be made in accordance with the present invention. In this embodiment, the mitt 558 may include a heat producing pouch 302 and a product dispensing pouch 30 that may be similar to that shown in FIG. 4. As shown in the cross-section FIG. 59, the top panel 564 may be constructed of a hydroentangled nonwoven having a basis weight of about 60 gsm that may includ...

example 3

[0174] Another example of an applicator made in accordance with the present invention is a rubber, vinyl, and plastic protectant mitt provided as a flexible structure for distributing cleaning, protecting, and shining formulations onto a target surface. Such an applicator may include a first fluid-containing reservoir having a predetermined amount, such as in the range from about 12 cc's to about 25 cc's of a protectant product. A protectant product is defined for the purposes of this application as a formulation that prevents drying, cracking, fading and / or discoloration caused by at least one or a combination of UV radiation, high temperature, ozone, dust and dirt. An exemplary protectant product that may be used in the present invention is an Armor-All® Protectant as available from The Armor All Products Corp., Oakland, Calif. The front panel 24 may be comprised of a synthetic woven, synthetic knit, nonwoven, apertured film, macroscopically expanded three-dimensional formed film,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com