Tracking system for distributable objects which are marked in single laser shot events with dynamically variable images

a technology of distributable objects and laser shot events, applied in the field of tracking systems, can solve the problems of counterfeit products reaching the end-user without being detected, counterfeit products pose a significant threat to the safety and integrity of supply chains, and counterfeit products also jeopardize the goodwill of well-established product brands, etc., and achieve no or, no smearing or blurring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] 1. Supply Chain Monitoring System

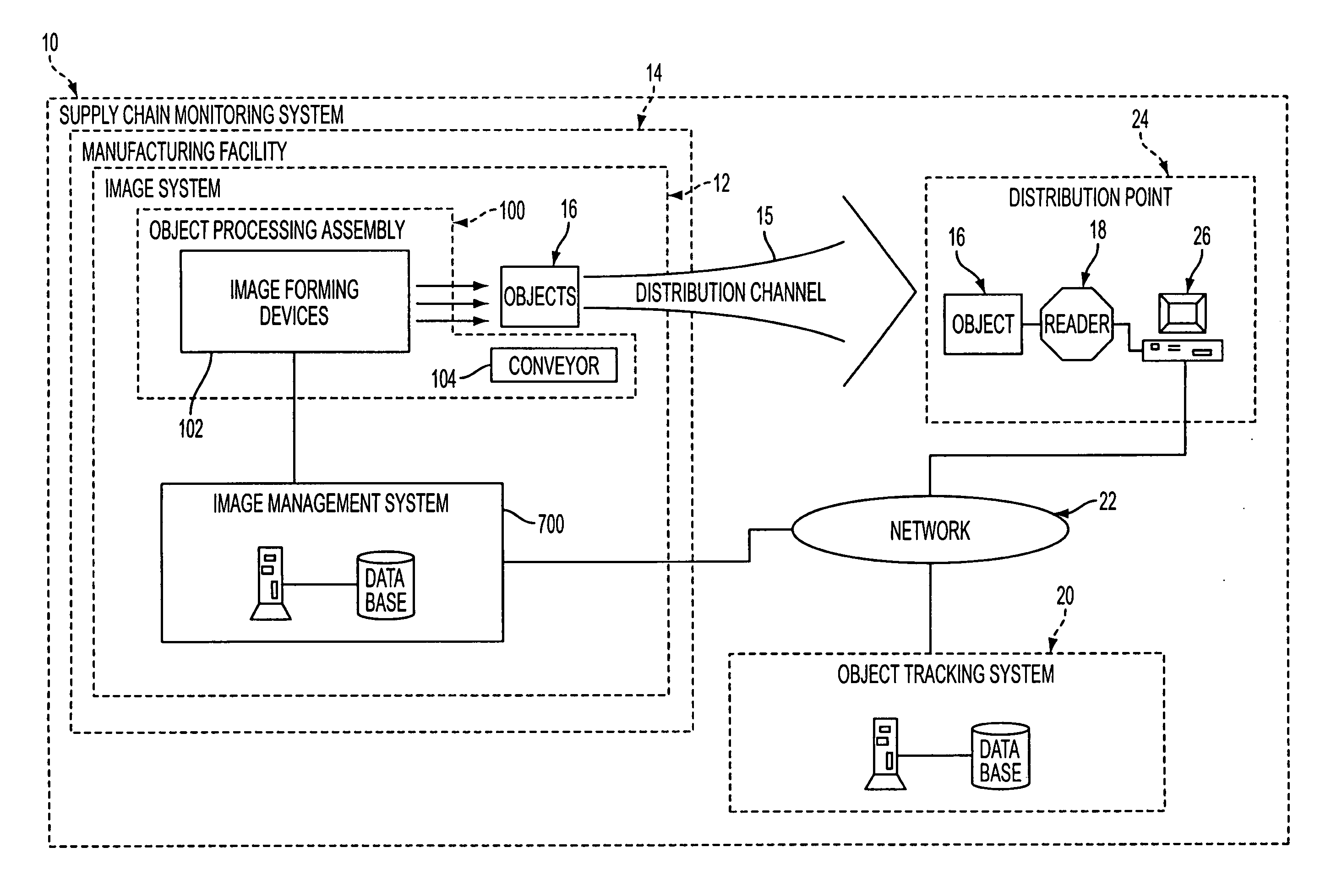

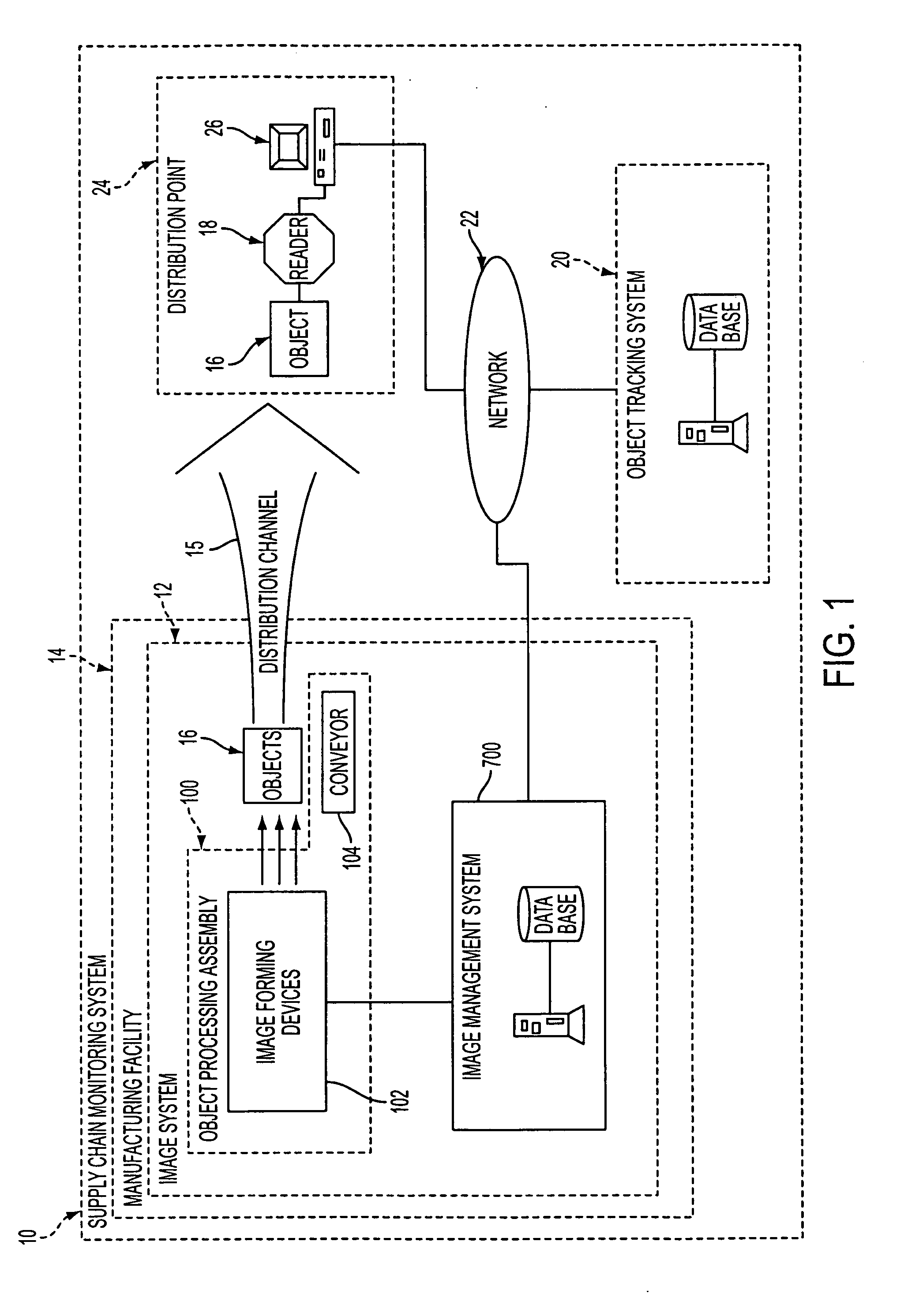

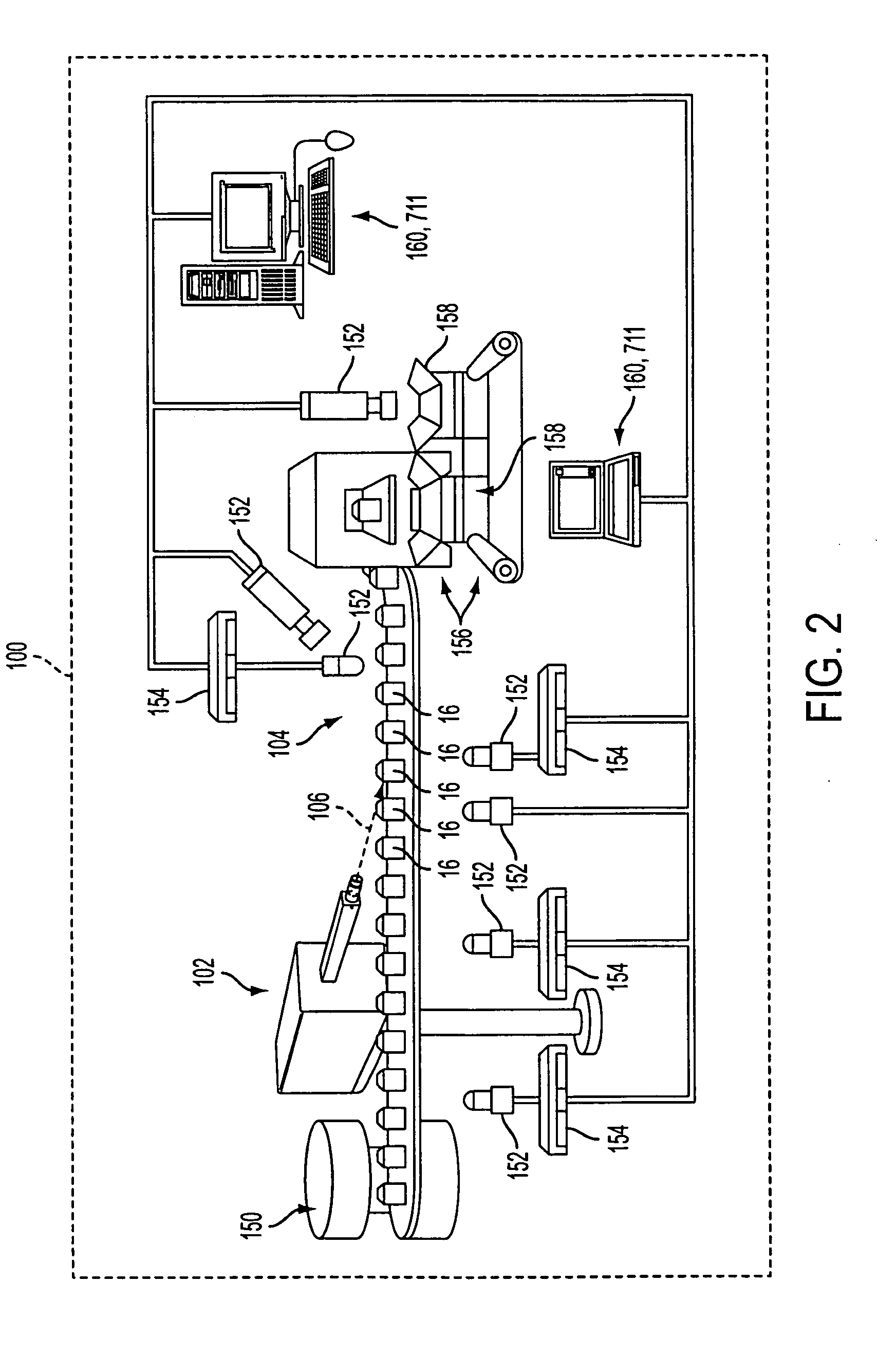

[0047] Referring now to FIGS. 1 through 38, the supply chain monitoring system 10, in one embodiment, includes: (a) a laser-based image system 12 which may be fully or partially housed or located within a manufacturing facility or object processing facility 14 and which is used to form images on products or objects 16; (b) a reader 18 which is operable to read the images on the objects 16; and (c) a product or an object tracking system 20 which is coupled to the reader 18 over a data network 22, such as the Internet or any other suitable network. The object processing facility 14 can include any building, facility or plant used to manufacture, package, process or otherwise treat objects. It should be appreciated that the image system 12 can form an image or marking on a relatively broad range of objects 16. The objects 16 can include, without limitation, products, goods and devices, such as: (a) pharmaceutical-related products and devices, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com