Dispensing spout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

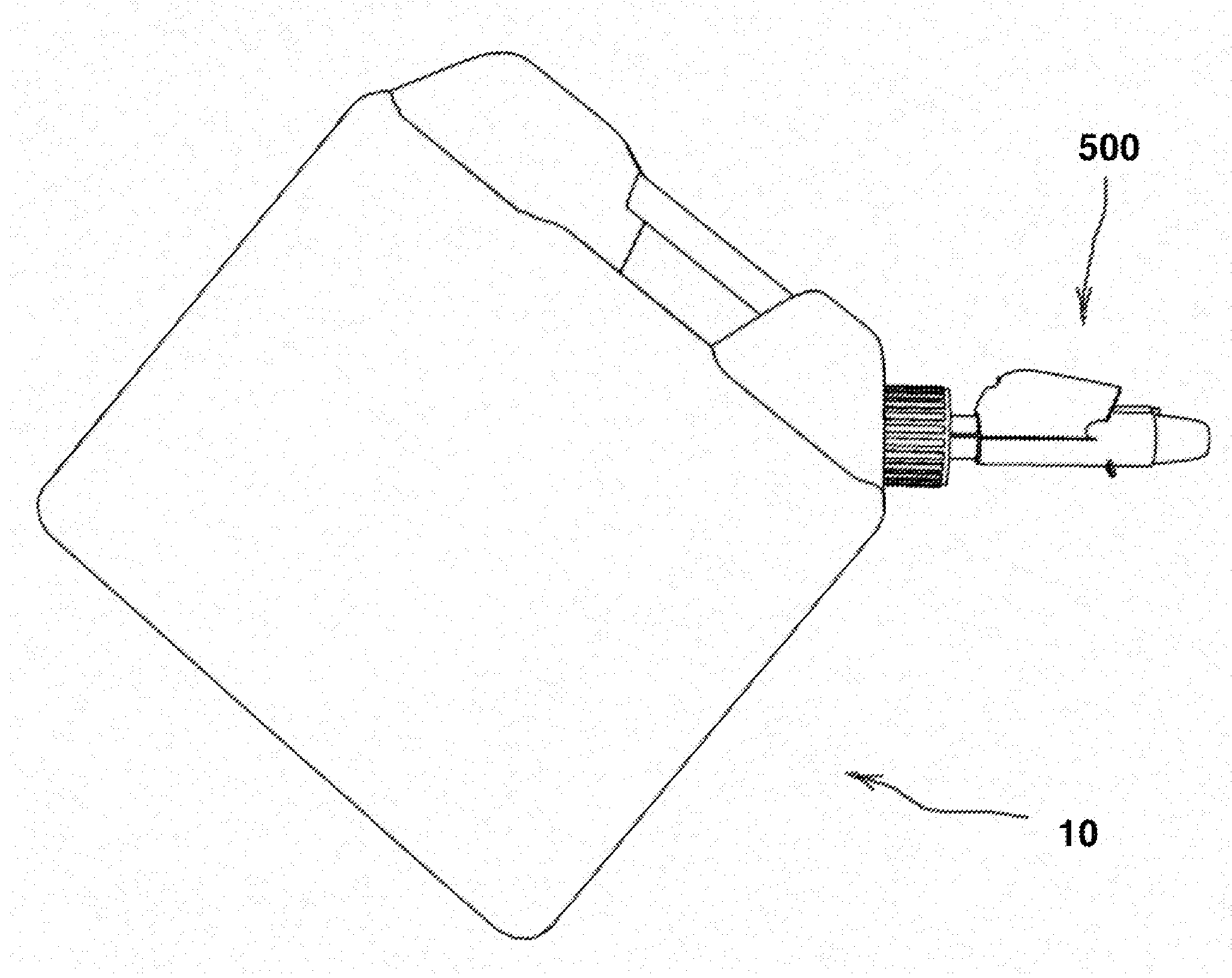

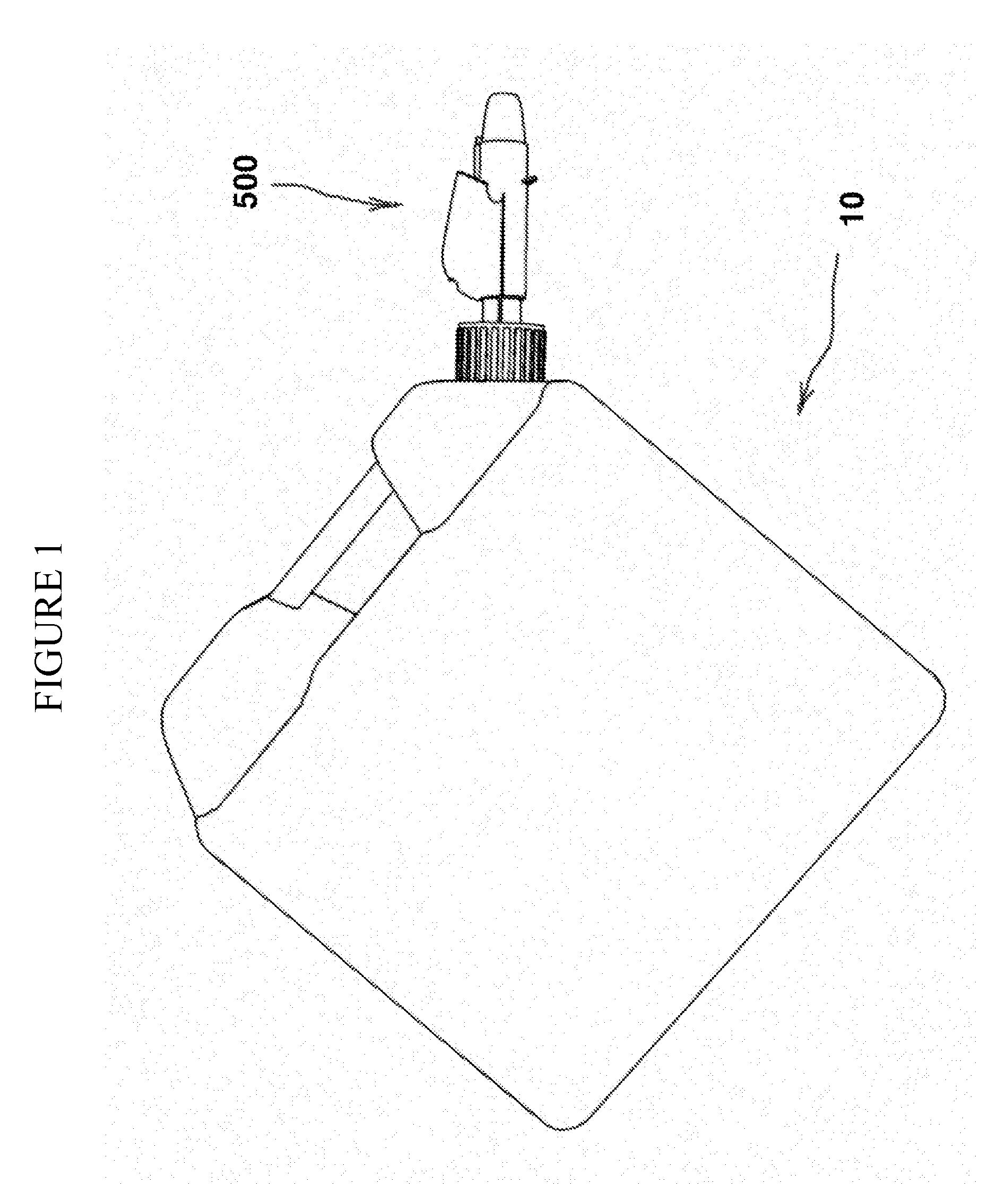

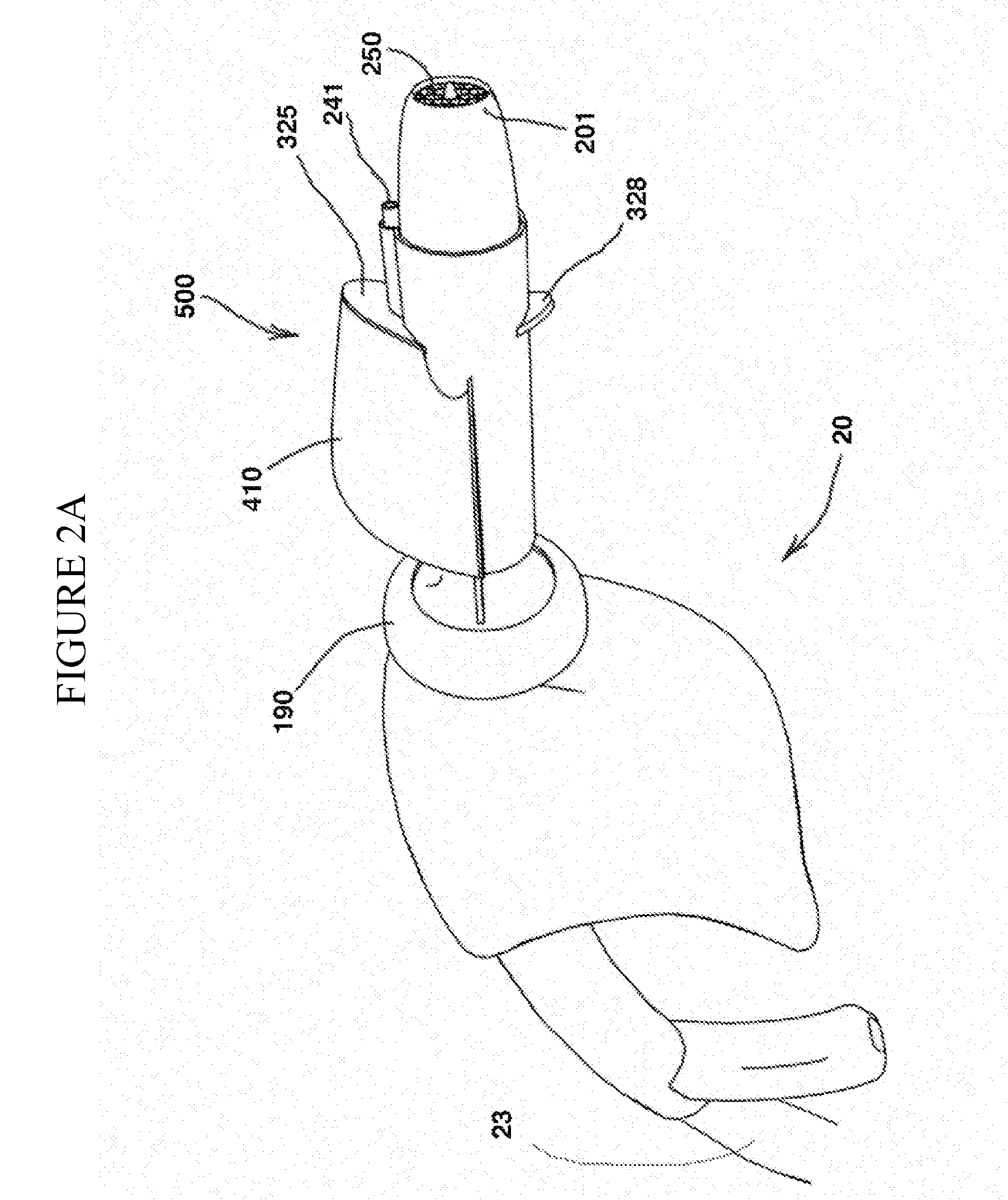

[0058] Referring to FIGS. 1 through 26 of the drawings, it will be noted that FIGS. 1 through 24 illustrate a first preferred embodiment of the dispensing spout of the present invention, and FIGS. 25 and 26 illustrate a second preferred embodiment of the dispensing spout of the present invention.

[0059] Reference will now be made to the FIGS. 1 through 24, which show a preferred embodiment of the dispensing spout of the present invention, as indicated by general reference numeral 20.

[0060] In this first aspect of the present invention, there is a dispensing spout 500 mountable to a liquid feeding means, such as a dispensing nozzle, hose, container, or the like, to provide a delivery system for delivering liquid from a liquid source, such as a portable fuel container 10, or the like, through a hose, such as a fuel hose, garden hose, or the like. The dispensing spout 500 comprises a casing 120 having an inlet 139 to receive liquid from the liquid source, such as the portable fuel con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

| Resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com