Means and method for fireproof sealing between the peripheral edge of individual floors of a building and the exterior wall structure thereof

a technology for individual floors and exterior walls, applied in the direction of walls, buildings, building roofs, etc., can solve the problems of severely compromising the fireproofing characteristics surrounding the particular floor, and compromising the positioning of spandrel insulation, so as to prevent the outer deflection of the safing stiffening means and prevent the overheating of the safing stiffening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

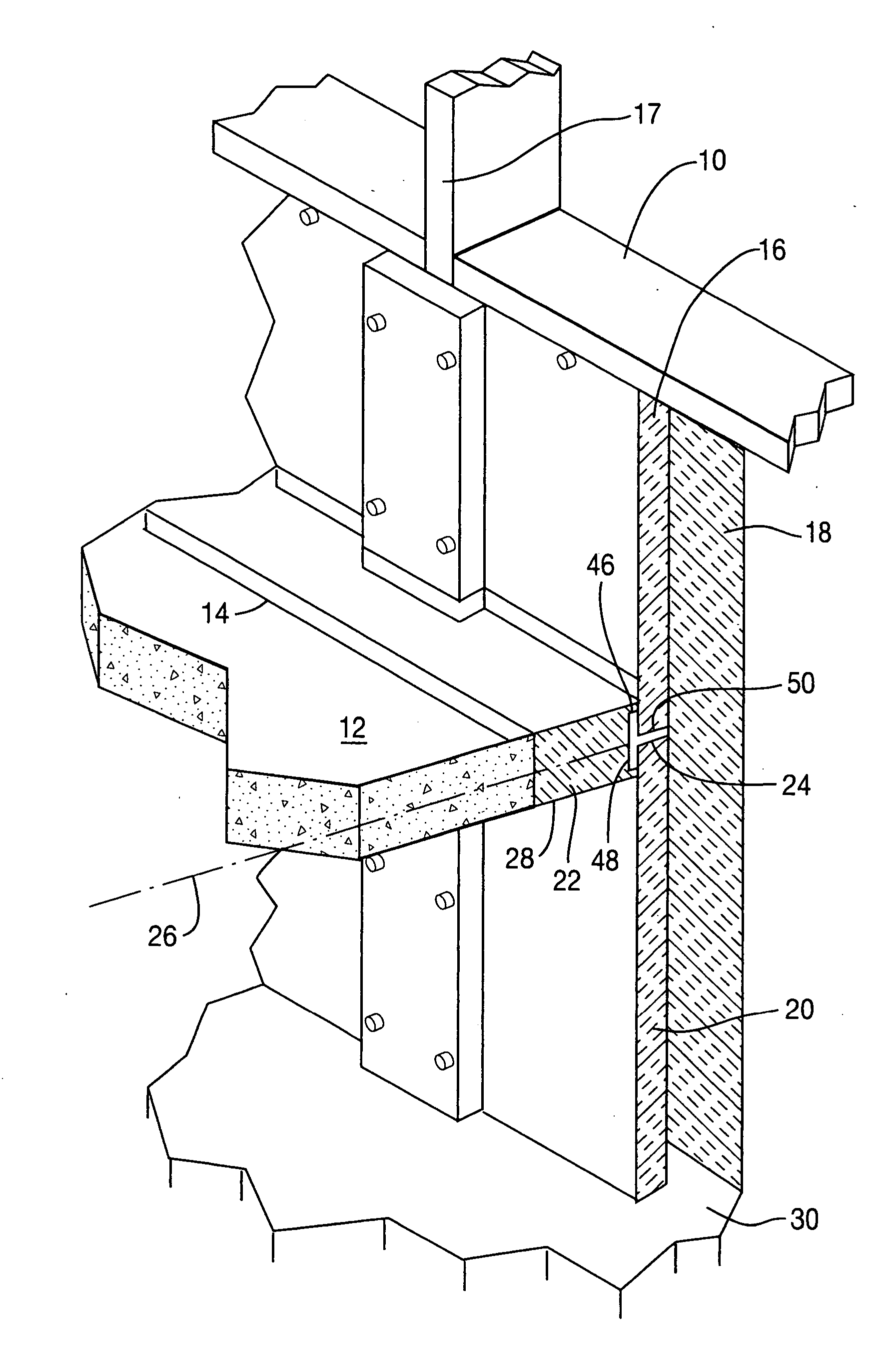

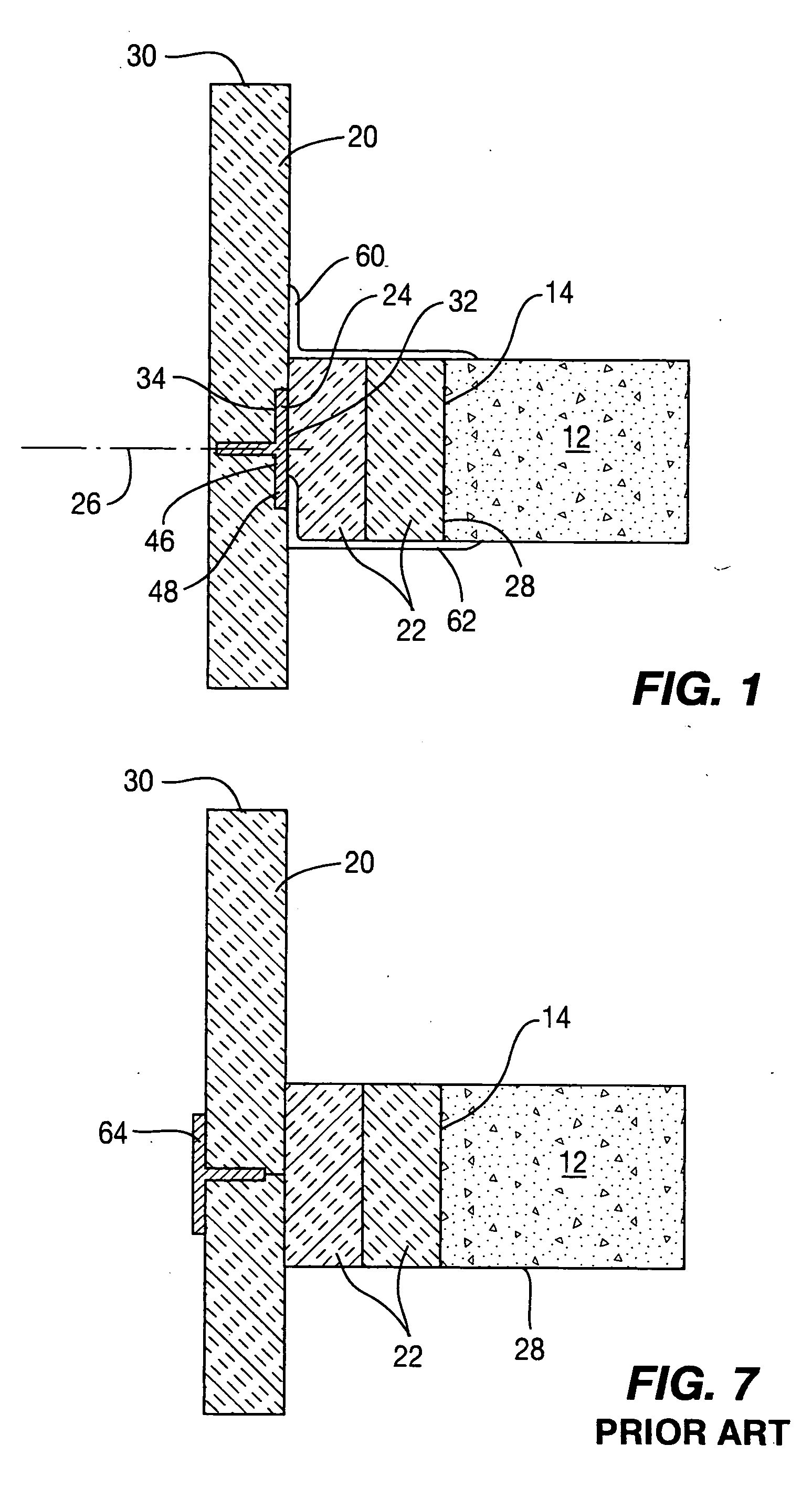

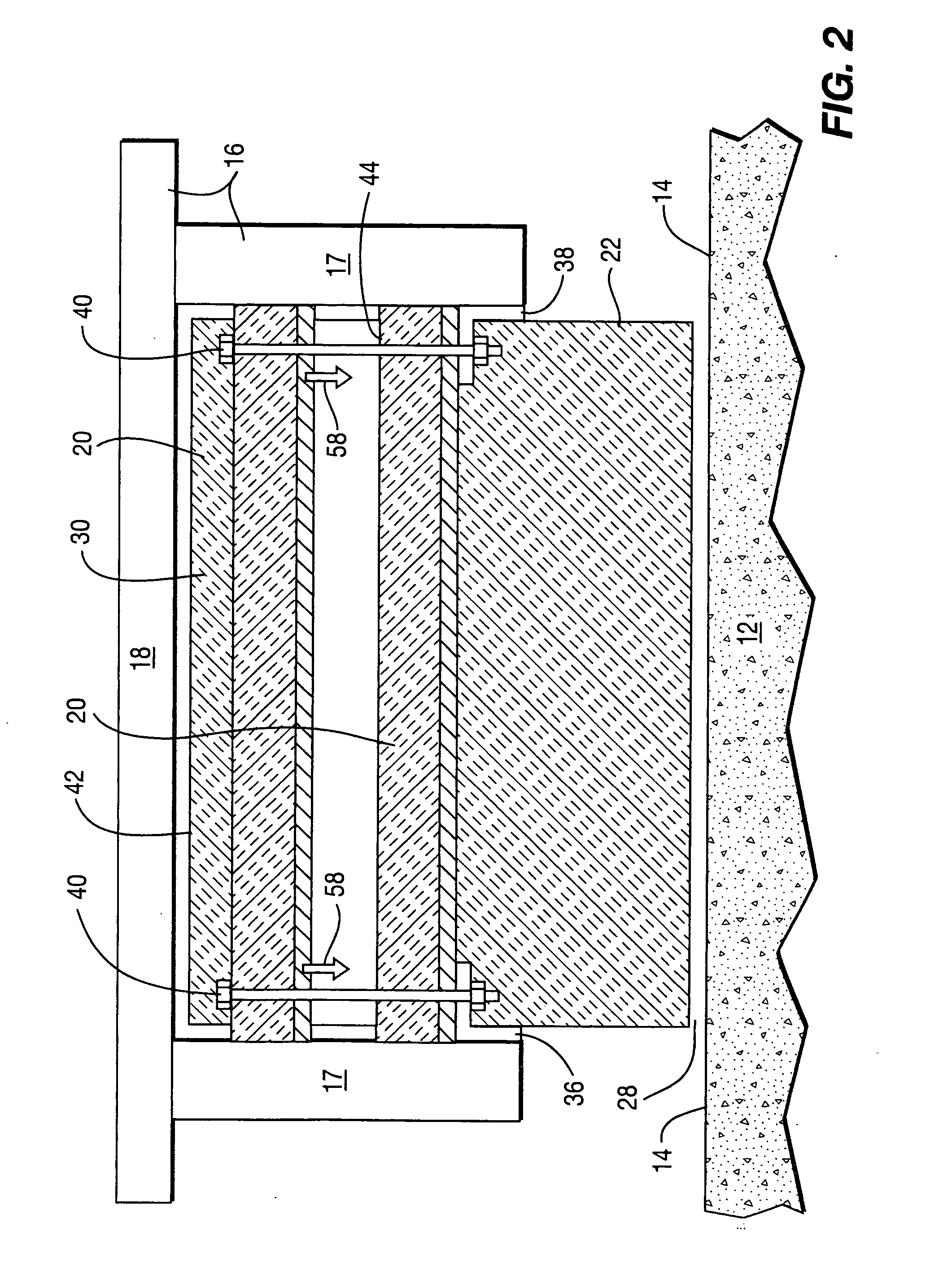

[0033] The present invention provides an improved means and method for providing a fireproofing seal within a building 10 about the individual floors 12 thereof, and particularly, about the outer peripheral edges 14 of these floors 12. A seal fireproofing seal needs to be provided between the exterior wall structure 16 and the peripheral edges 14 of the floor 12 in order to prevent the movement of hot gases, fire, smoke and heat upwardly therethrough in order to prevent fire from spreading upwardly within a building by maintaining compartmentalization of the building and of the fire located within a particular floor therein. The exterior wall structure 16 of the conventional building includes vertically extending wall members 17 which can comprise studs of wood or metal often in commercial buildings formed of aluminum. These vertical wall members 17 are spaced apart from one another, and spandrel panels 18 are secured extending thereover normally used as a portion of the exterior cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com