Dichroic azo dyestuff and the polarizing film making from the same

a technology of dichroic azo dyestuff and polarizing film, which is applied in the direction of polarizing elements, lighting and heating apparatuses, instruments, etc., can solve the problems of low polarized efficiency, still not meeting the requirements of heat and moisture proof in some situations, and reducing the efficiency of polarization within the elapsed tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0036]Preparing the azo-dyestuff compound of formula (1):

[0037]The above azo-dyestuff compound of formula (1) can be obtained, according to the following three steps:

1. DiDiazotization:

[0038]

[0039]40 parts of 4-amino-4′-nitrostilbene-2,2′-disulfonic acid (A) was dissolved in 300 parts of water and 30 parts of 32% hydrochloride acid was added, followed by stirring at 0-5° C. Diazotization was realized with the addition of 8 parts of sodium nitrite at the same temperature range.

2. Coupling Reaction:

[0040]

[0041]35.12 parts of 2-amino-5-hydroxynaphthalene-1,7-disulfonic acid (C) was dissolved in the mixture of 200 parts of cool water and 35 parts of sodium carbonate, to which the above reagent (B) from Diazotization was then added dropwise. Thereby, the coupling reaction was realized. After the reaction was completed, the monoazo compound of free acid (D) was obtained by filtration.

3. Semi-Reduction:

[0042]

[0043]The monoazo compound (D) was dissolved in 400 parts of water, followed by th...

examples 2 to 12

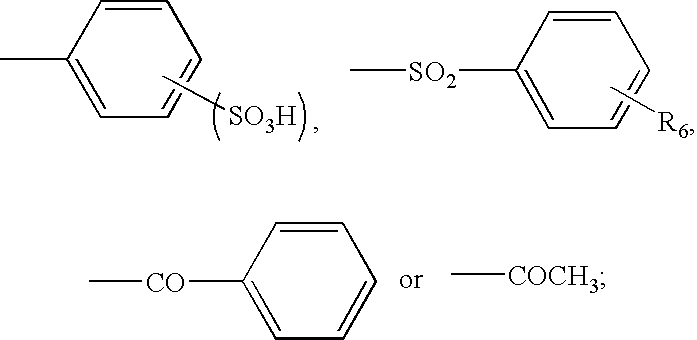

[0044]Repeat the reaction steps of Example 1, but the 2-amino-5-hydroxynaphthalene-1,7-disulfonic acid of reactant (C) is replaced with the following reactant (C) as shown in Table 1. After completed the reaction, the reaction solution are filtered and dried to obtain the products of formula (2) to formula (12) as shown in Table 1. The A max of the compounds of formula (2) to formula (12) in water were presented in Table 1.

TABLE 1ExampleReagent (C)Productλ max 1Formula (1)530 nm 2Formula (2)600 nm 3Formula (3)538 nm 4Formula (4)600 nm 5Formula (5)555 nm 6Formula (6)575 nm 7Formula (7)532 nm 8Formula (8)522 nm 9Formula (9)532 nm10Formula (10)585 nm11Formula (11)585 nmExample12Formula (12)540 nm

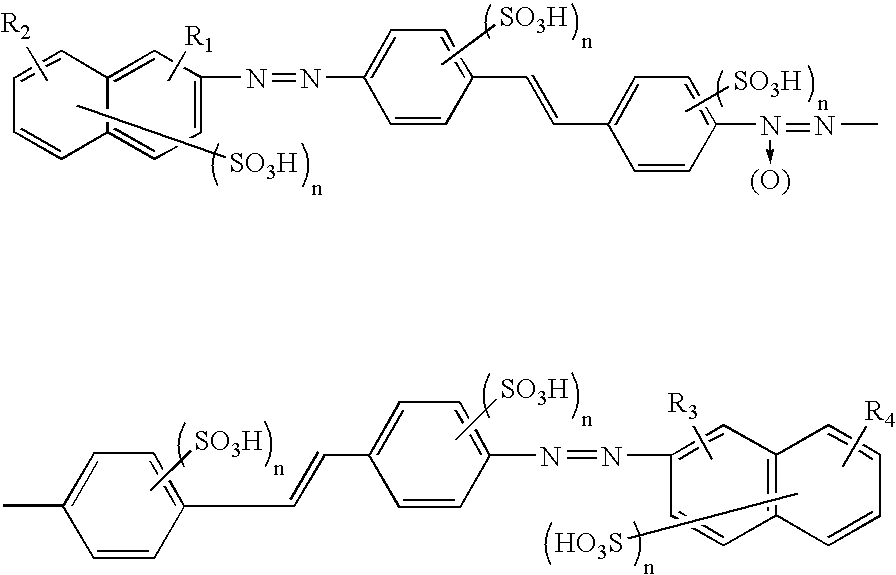

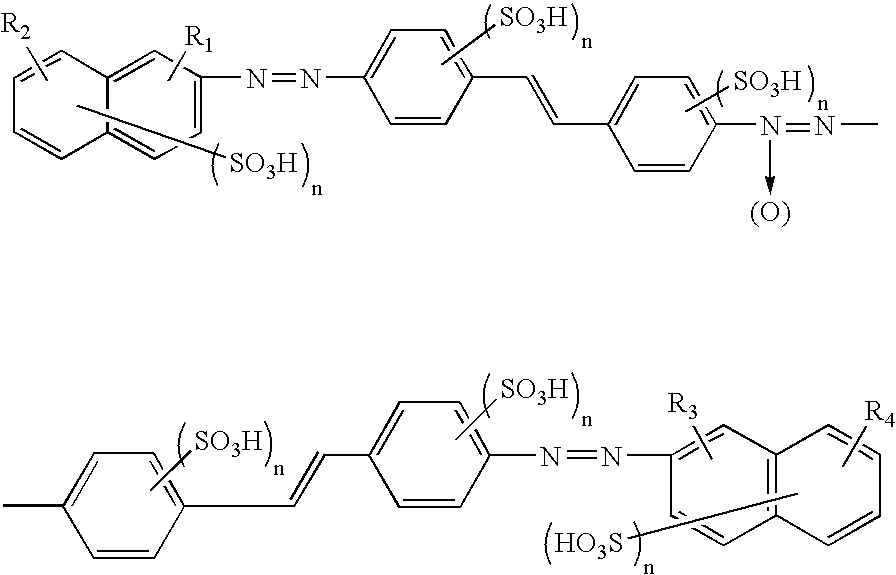

The following is the structure of formula (1) to (12) compounds:

[0045]The following Examples 13 to 24 are related to the preparation of the dye type polarizing films of the present invention and the measurement of light polarization.

[0046]According to Example 13 to 24, the polarizing films can ...

example 13

[0051]The polyvinyl alcohol film of 75 μm thickness, Kuraray vinylon 7500 made from Kuraray, was stretched five-fold longer in one vertical direction and the base material of the polarizing film was obtained. The polyvinyl alcohol film in strain form was dipped in the 65° C. solution of 0.025% azo compound of formula (1) made from Example 1 and 2.0% sodium sulfate (served as a dyeing agent). Then, the film was dipped in 7.5% boric acid at 65° C. for five minutes, followed by taking out the film. The polarizing film was obtained after it was washed with 20° C. water for 20 seconds and dried at 50° C. The characteristics of the polarizing film are V=99.97 and Ts=45.07. The polarizing film with high-polarized efficiency does not discolor under the high-temperature and high-moisture condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com