Vertically adjustable pipe support apparatus

a support apparatus and vertical adjustment technology, applied in the direction of mechanical equipment, machine supports, other domestic objects, etc., can solve the problems of the cost of installing the pipe system, unnecessary and awkward projection of the upper portion, and increasing the number of procedures. , to achieve the effect of increasing the safety of persons and being convenient to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

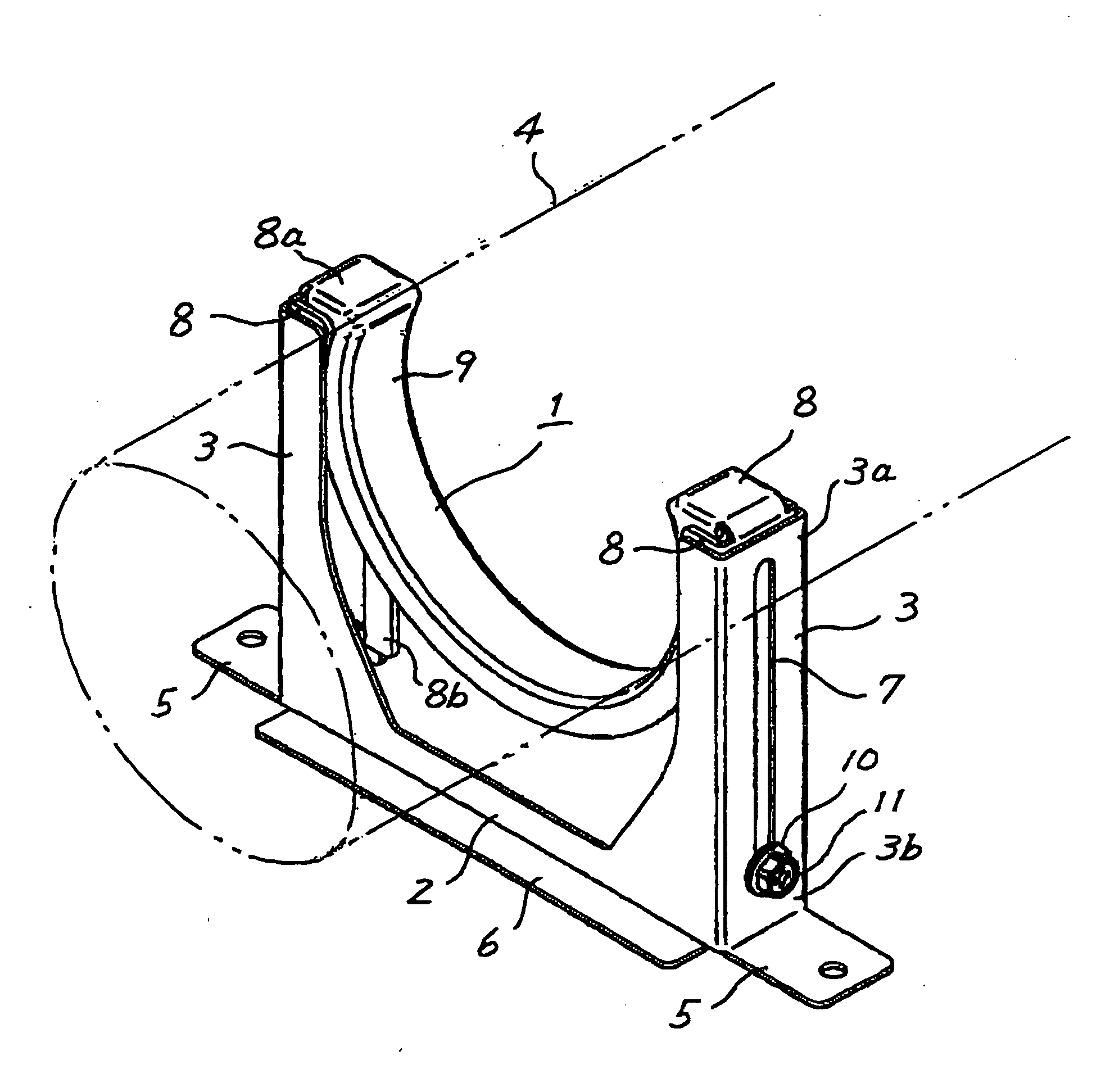

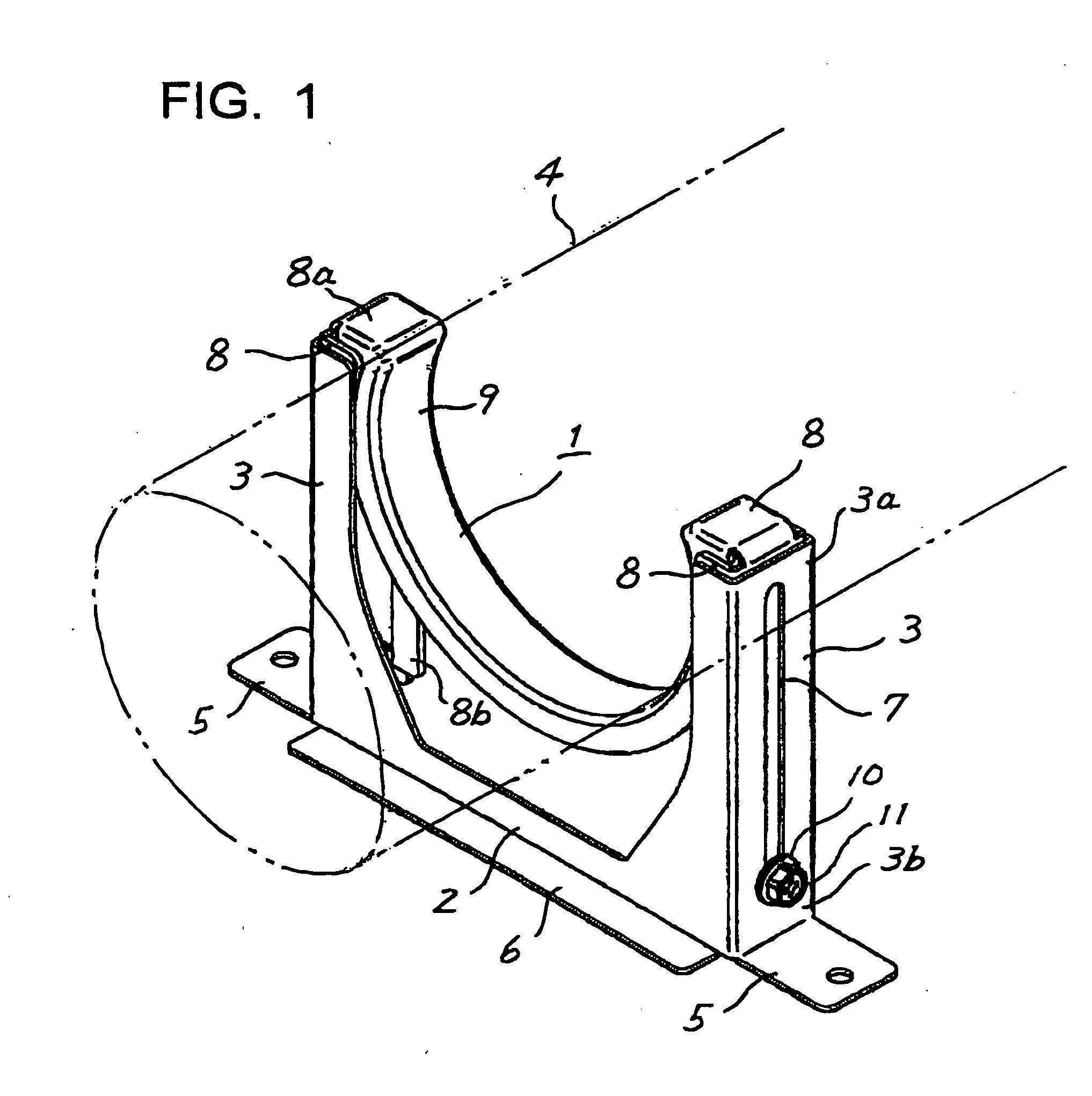

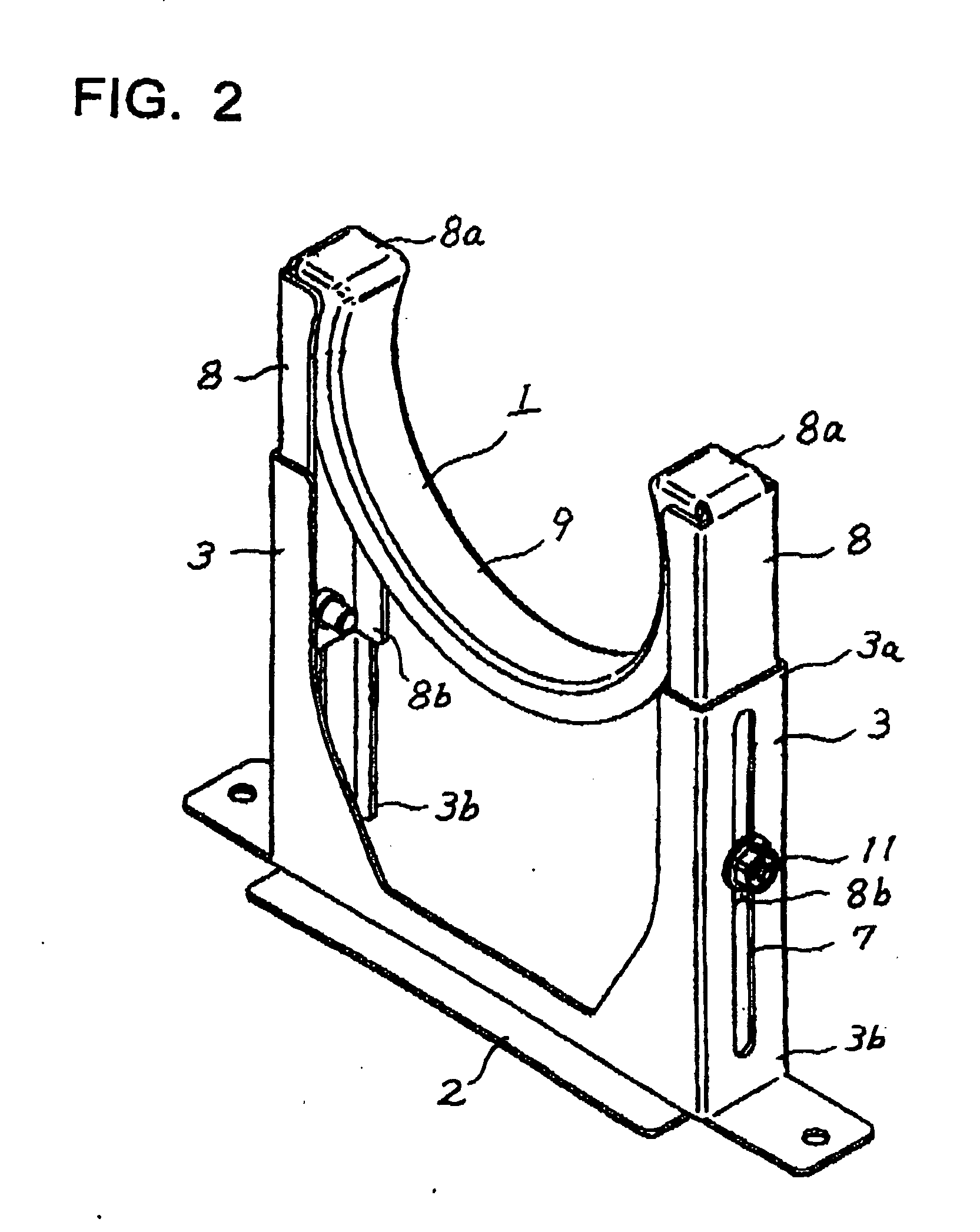

[0020] FIGS. 1 to 3 illustrate an embodiment of a pipe support apparatus 1 of the present invention, which comprises a base 2 and a first and second support pillar 3 mounted in parallel to each other on the base 2 and separated from each other by a distance larger than the diameter D of a pipe 4 to be supported. The base 2 and the two support pillars 3 in this embodiment are manufactured from a substantially U-shaped single piece of sheet metal so that they are integrally formed with each other. Each of the two legs of the U-shaped piece of sheet metal is bent along its length to form one of the support pillars 3, each of which has a substantially U-shaped cross section, a top end 3a, and a bottom end 3b. The leg portions of the support pillars 3 have outwardly extending tabs 5 at their bottom ends 3b. The bight portion of the U of the piece of sheet metal is bent at its bottom edge to form an outwardly extending flange 6 which, together with the tabs 5, forms the base 2. Each suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com