Packaging for butter or similar products

a technology for butter and similar products, applied in the direction of tight containers, tamper-indication equipment, closures, etc., can solve the problems of easy mechanical damage, greasy fingers, and unappetizing yellow areas that are easily affected by mechanical damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

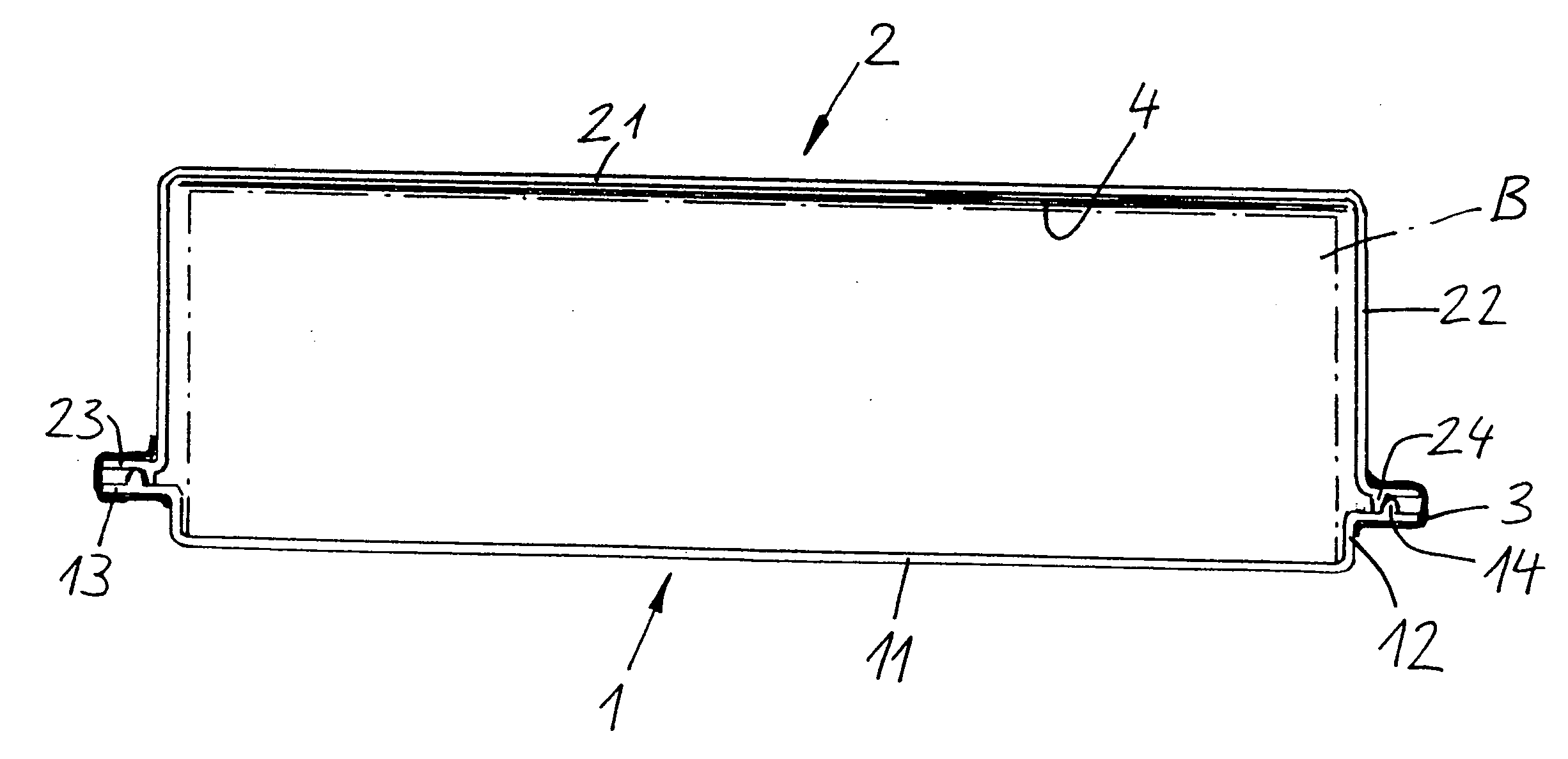

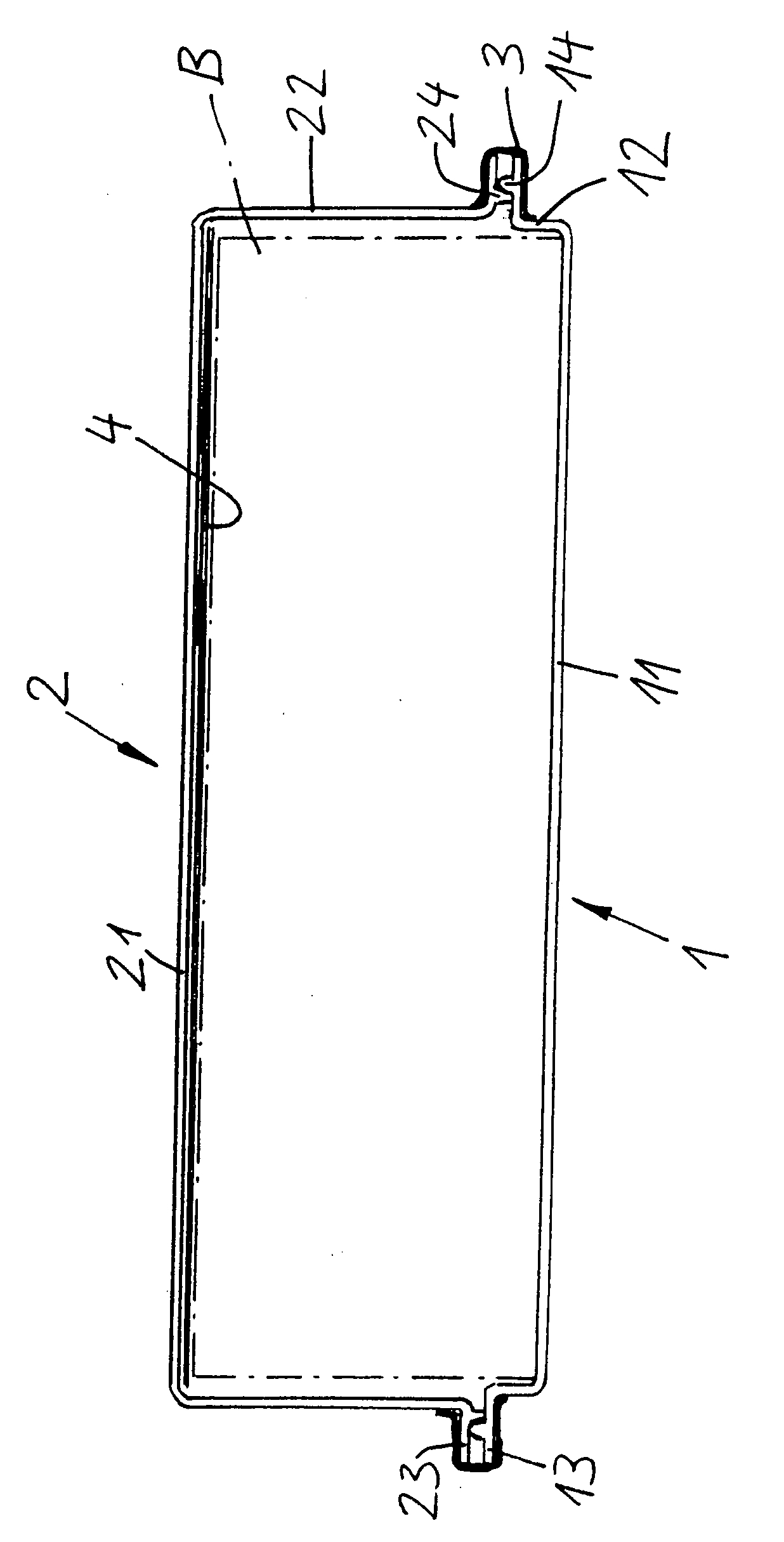

[0011] The sole FIGURE shows in a cross-sectional view of a butter packaging according to the invention.

DESCRIPTION OF A PREFERRED EMBODIMENT

[0012] The packaging according to the invention comprises a bottom part 1 and a top part 2, which parts are joined via a sealing rim 3. The bottom part 1 and the top part 2 are preferably injection-molded from a plastic material. The complete two-part packaging is in principle like a butter container with a flat bottom part and a high cover part, but is in the form of a sales packaging. The sealing rim 3 comprises a plastic foil which is welded together with the bottom part and the top part.

[0013] The bottom part 1 has a flat bottom wall section 11, a low side wall section 12 projecting upwardly from circumferential edge of the flat bottom wall section 11 and including a circumferential horizontal flange 13 of a width as needed.

[0014] The butter piece B disposed in the packaging is shown by a dash-dotted line. It has a small distance from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com