Refrigerant compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

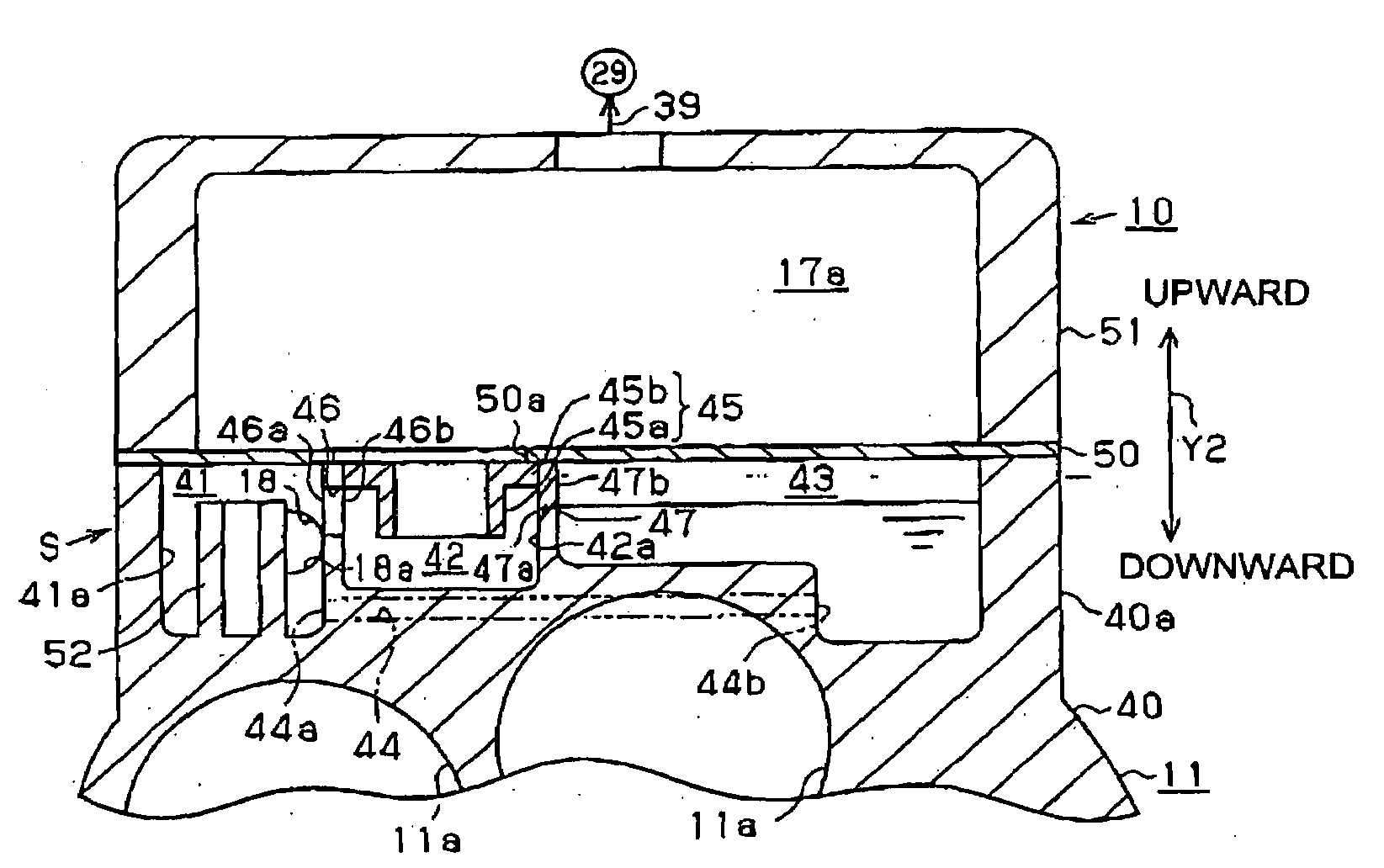

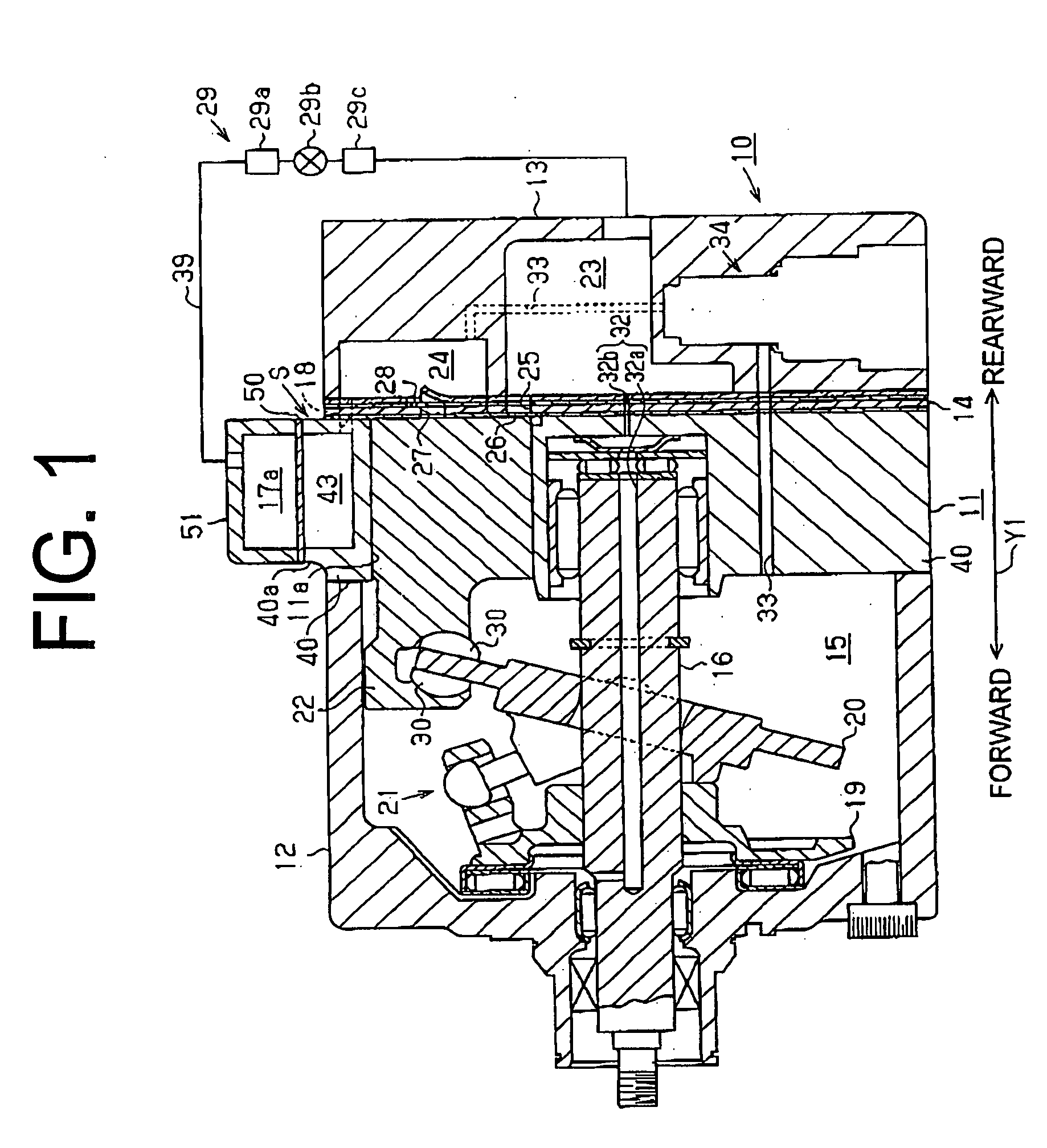

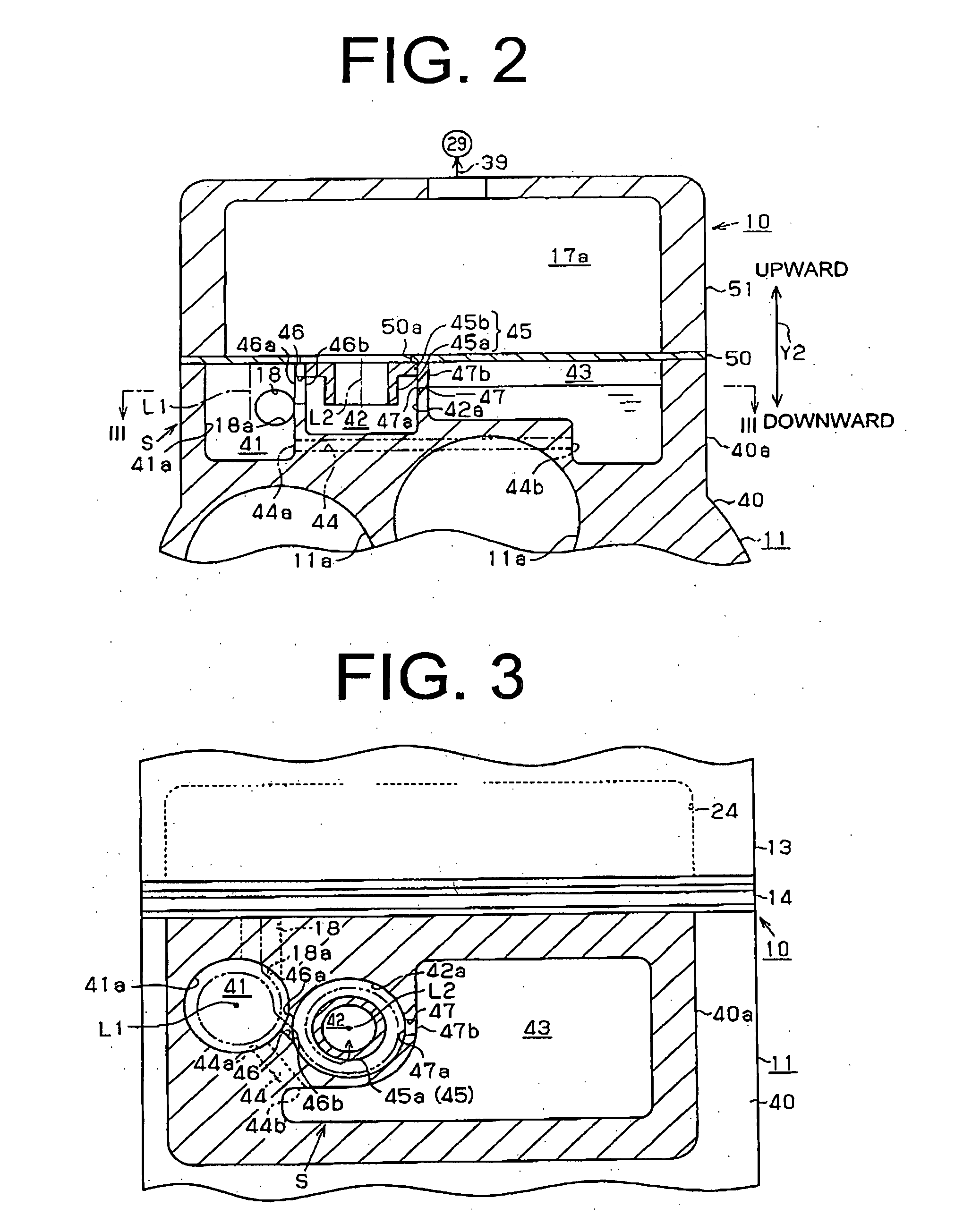

[0014]An embodiment of a variable displacement swash plate compressor for vehicle air conditioners according to the refrigerant compressor of the present invention will now be described with reference to FIGS. 1 to 3. In the following description, the direction of arrow Y1 shown in FIG. 1 corresponds to the “front” and “rear” (longitudinal) direction of the variable displacement swash plate compressor, and the direction of arrow Y2 shown in FIG. 2 corresponds to the “upper” and “lower” (vertical) direction thereof.

[0015]As shown in FIG. 1, the housing of the variable displacement swash plate compressor (hereinafter referred to simply as a “compressor”) 10 includes a cylinder block 11, a front housing 12 fixedly joined to a front end of the cylinder block 11, and a rear housing 13 fixedly joined to a rear end of the cylinder block 11 through a valve plate assembly 14. Each of the cylinder block 11, the front housing 12 and the rear housing 13 serves as a housing component. The cylind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap