Negative pressure tabletop dust collecting machine

a negative pressure technology, applied in cleaning equipments, manufacturing tools, separation processes, etc., can solve the problems of large volume, complicated structure, and large volume of the dust collection unit of the conventional tabletop dust collection machine, so as to simplify the structure, reduce the volume, and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

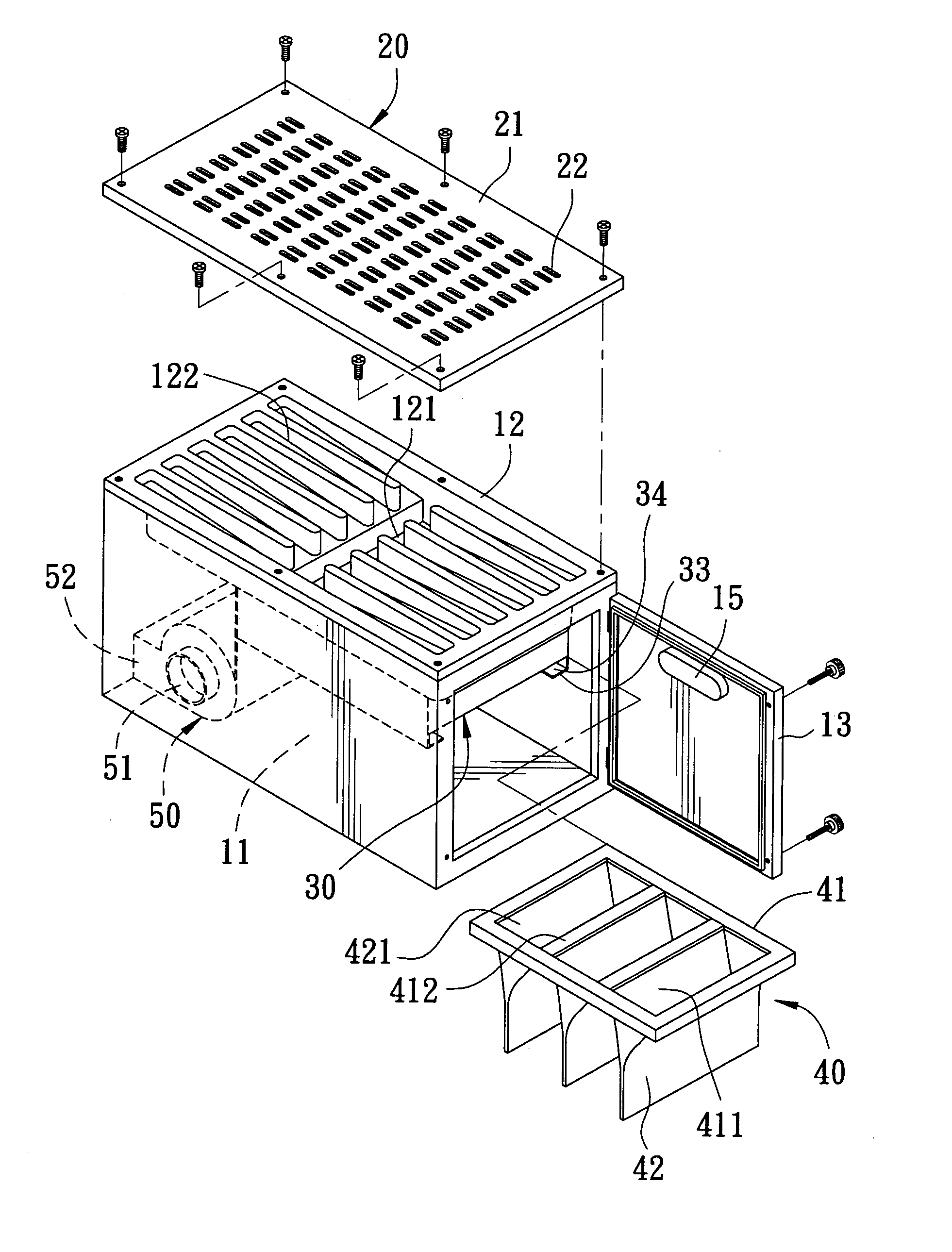

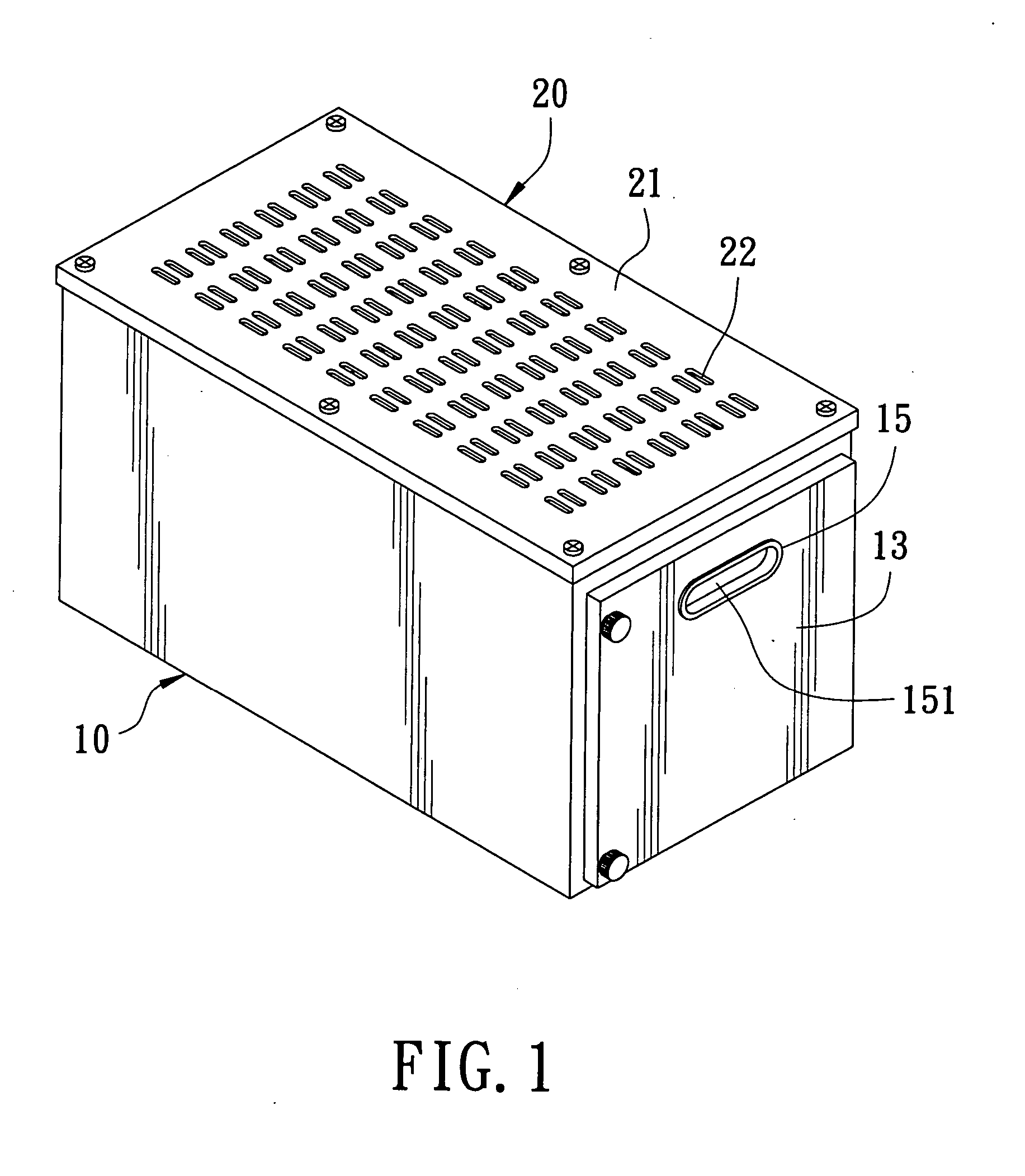

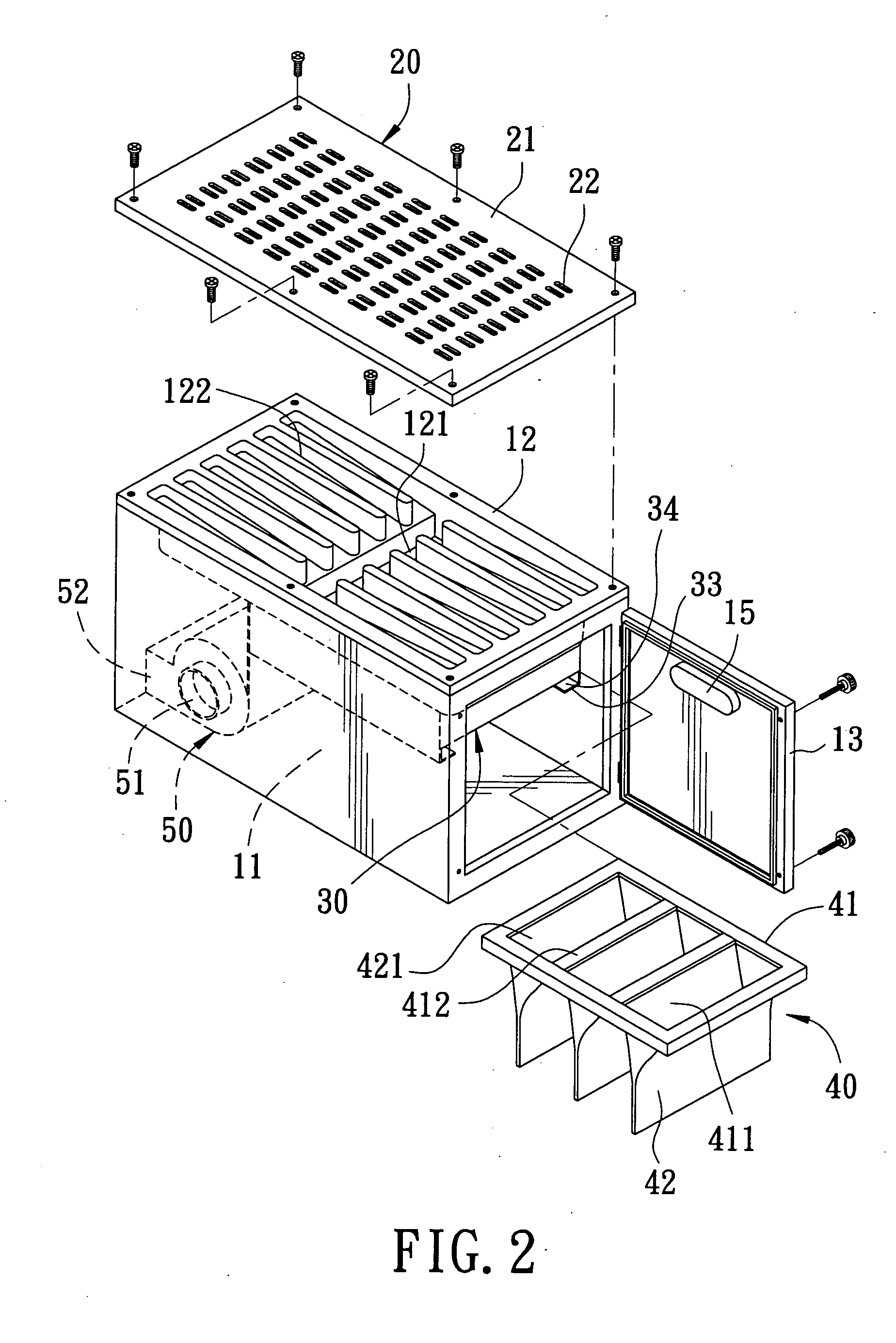

[0012] A preferred embodiment of a negative pressure table-top dust collecting machine in the present invention, as shown in FIGS. 1, 2 and 3, includes a machine box 10, an operation faceplate 20, a fixing base 30, a dust collecting unit 40 and a blower 50 combined together.

[0013] The machine box 10 is formed with a closed interior space 11 and has the intermediate portion of its top wall 12 bored with a vertical wind vent 121 and has the upper left and right side of the top wall 12 respectively and symmetrically bored with a plurality of recessed guide grooves 122, which have their bottoms slanting downward toward the wind vent 121. Further, the machine box 10 has its right side wall pivotally assembled with a door plate 13 able to be opened and closed and has its left side all bored with a wind-exhausting opening 14 near the lower side. In addition, the machine box 10 has its left wall and its doorplate 13 respectively provided near the upper side with a grasping member 15 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| vacuum suction force | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com