Coal bed pretreatment for enhanced carbon dioxide sequestration

a technology of enhanced carbon dioxide and coal bed, which is applied in the direction of climate sustainability, sustainable manufacturing/processing, borehole/well accessories, etc., can solve the problems of consuming energy in the separation process, unable to achieve the effect of enhancing methane recovery, and no hydrogen alone can solve the problem of displacing methane from the pores of underground coal bed to enhance the carbon dioxide storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

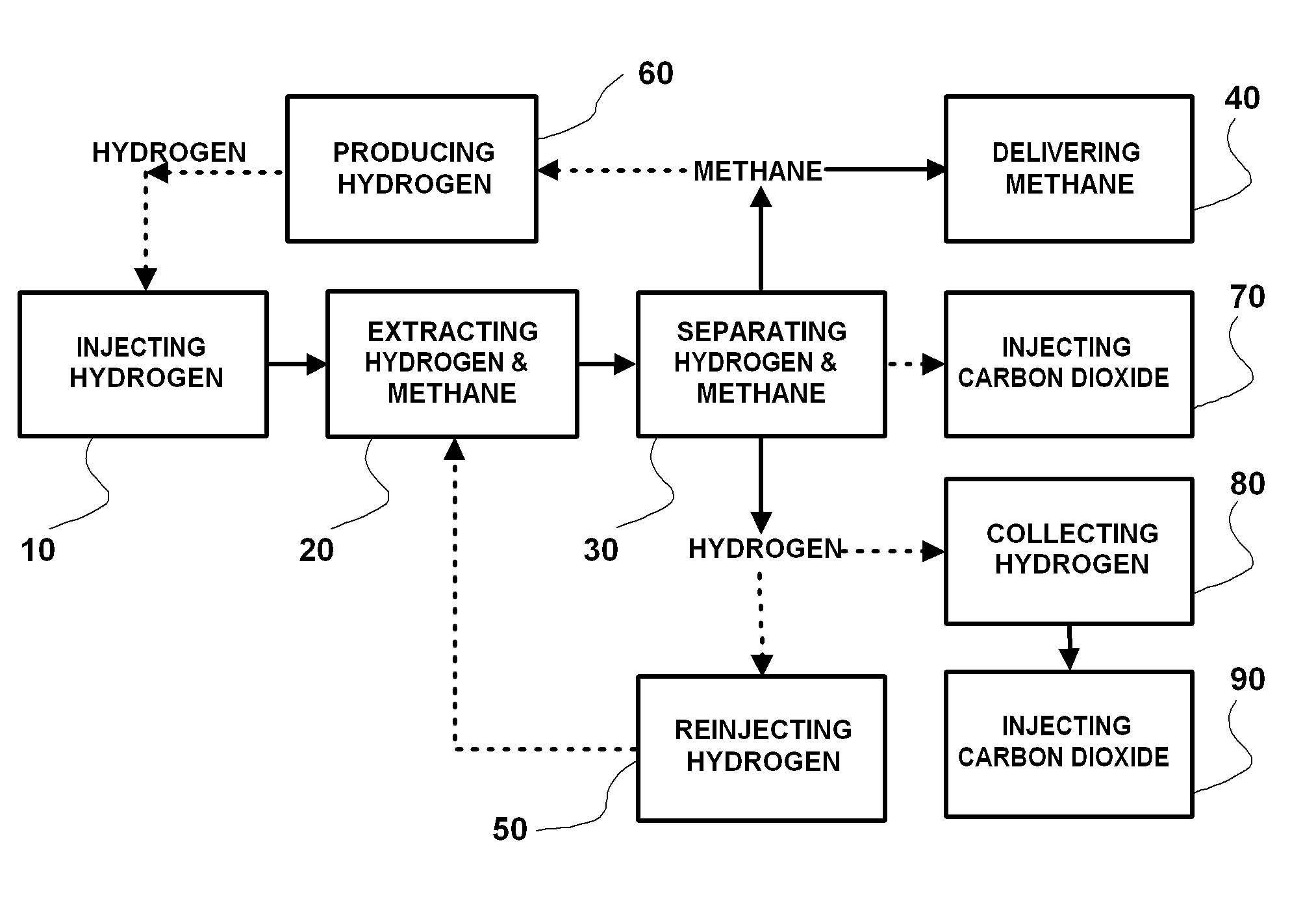

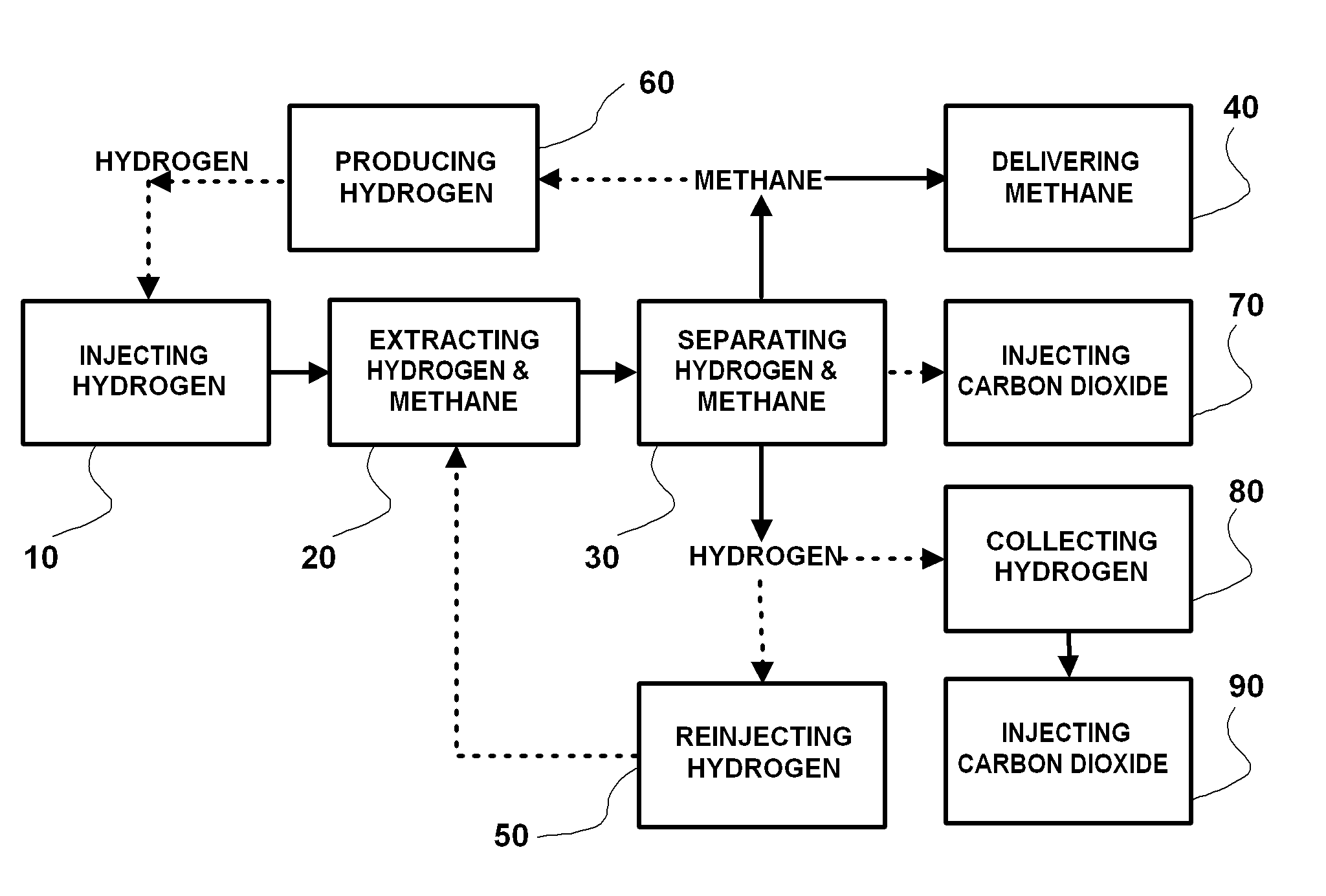

[0029] In the following description, reference is made to the accompanying drawing, which forms a part hereof and which illustrates several embodiments of the present invention. The drawing and the preferred embodiments of the process are presented with the understanding that the present invention is susceptible of embodiments in many different forms and, therefore, other embodiments may be utilized and operational changes may be made without departing from the scope of the present invention.

[0030] The process employs hydrogen for pretreating an underground coal bed to enhance: (1) the potential for carbon dioxide sequestration by removing adsorbed methane and methane trapped within pores of the coal bed, and (2) methane production.

[0031] There are five fundamental steps to the base process. 1. injecting hydrogen into an underground coal bed, wherein the hydrogen is at a temperature below about 800 degrees Centigrade; 2. extracting hydrogen and methane from the coal bed; 3. separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com