Building system, beam element, column and method

a building system and beam technology, applied in the direction of structural elements, building components, load-supporting elements, etc., can solve the problems of limited degree of flexibility, limited strength of reinforcements, and labor-intensive retrofitting or modifying lines, so as to increase the strength of reinforcements, reduce labor intensity, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

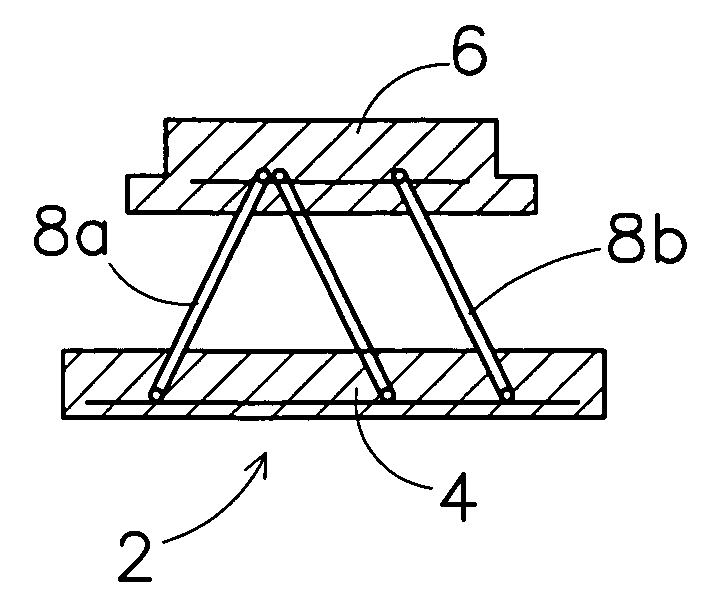

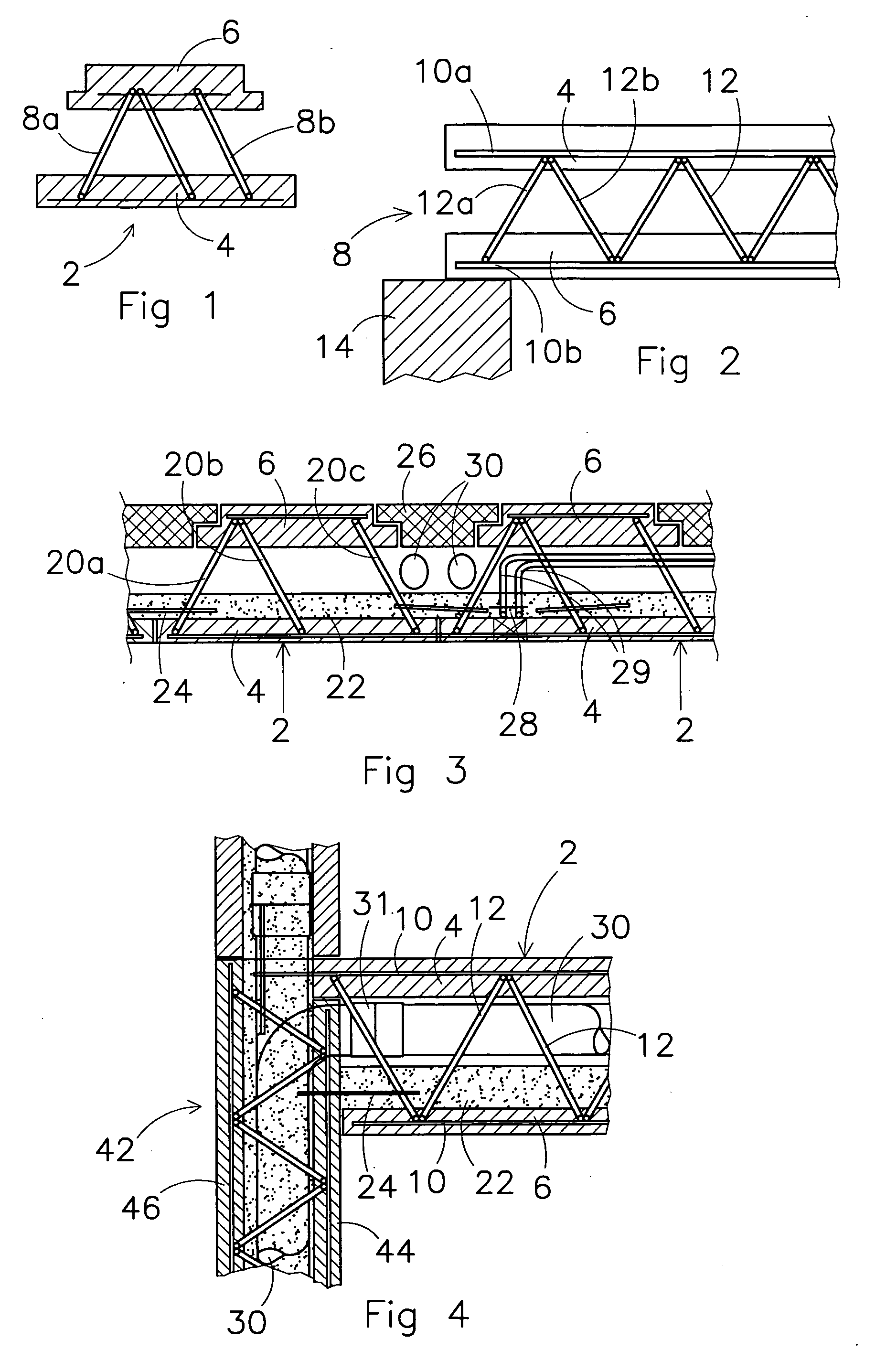

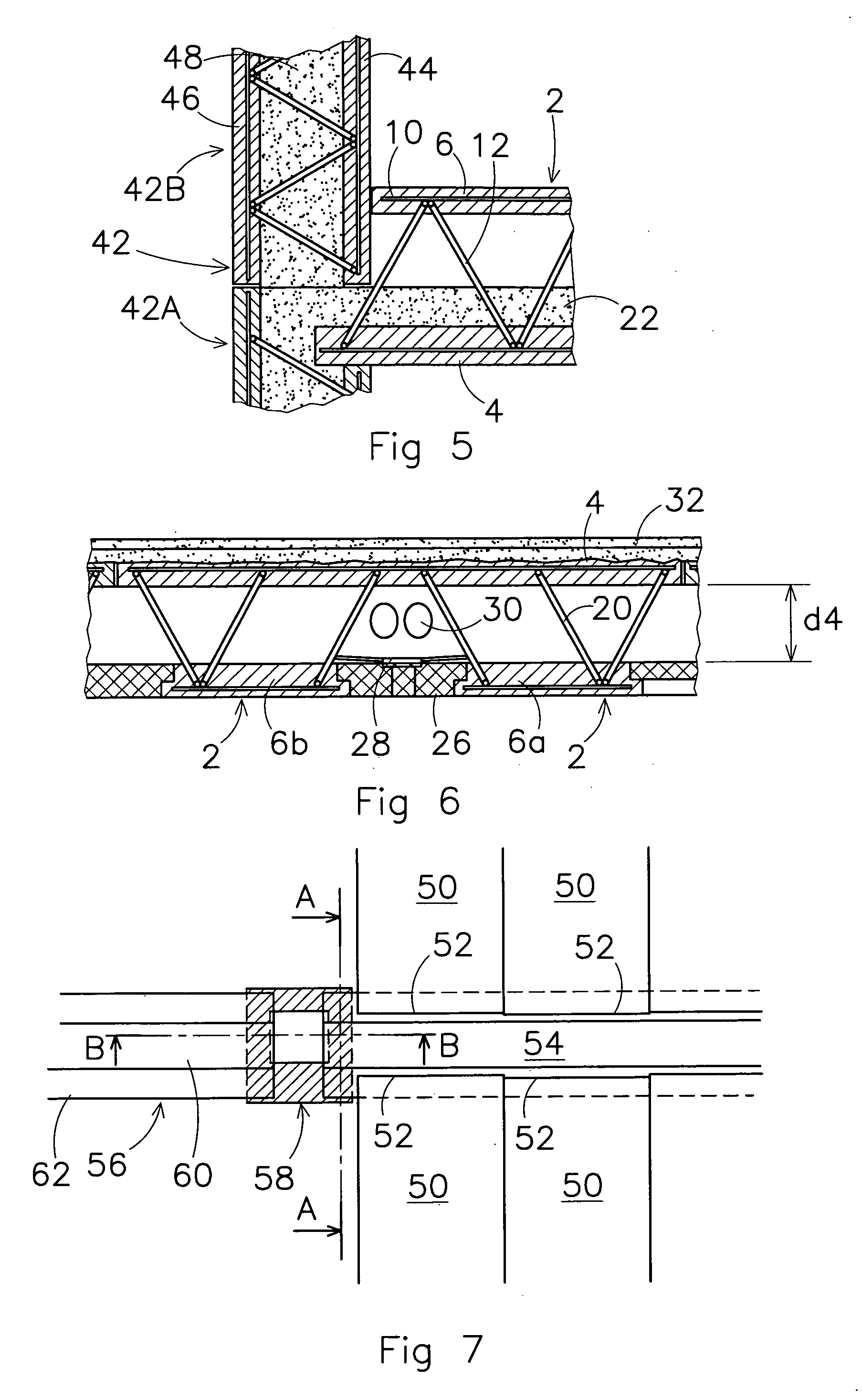

[0059]FIG. 1 shows a building element 2 which comprises a first concrete slab 4 and a second concrete slab 6. Along a part of the length of the concrete slab, the second concrete slab 6 has a smaller width than the first concrete slab 4, the width being in the plane of the paper. The length of the first concrete slab 4 may be equal to the length of the second concrete slab 6 or one of the two lengths may be less than the length of the other slab, depending on the application and the chosen design. A metal load-bearing structure is arranged between the first and the second concrete slab 4, 6. The building element comprises a first supporting element 8a and a second supporting element 8b. The supporting elements 8a and 8b are at an angle with respect to one another for the purpose of structural rigidity and strength.

[0060] If desired, a building element 2 may comprise more supporting elements, for example depending on the desired width of the building element 2, a minimum weight to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com