Interlocking structure for floor panel

a technology of interlocking structure and floor panel, which is applied in the direction of walls, constructions, building components, etc., can solve the problems of still sinking or opening of the joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

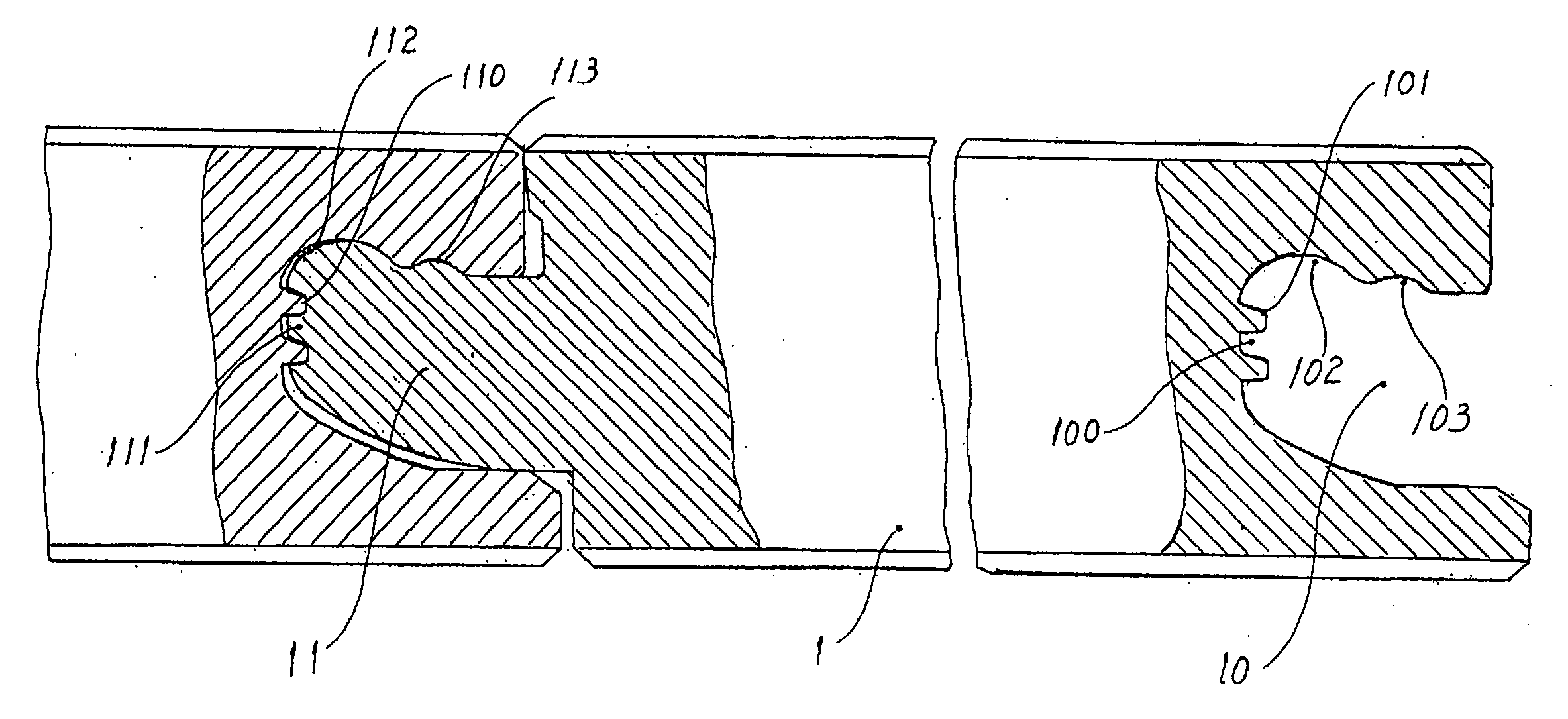

[0008]FIG. 1 is a schematic drawing of the cross-section of first embodiment of the present application.

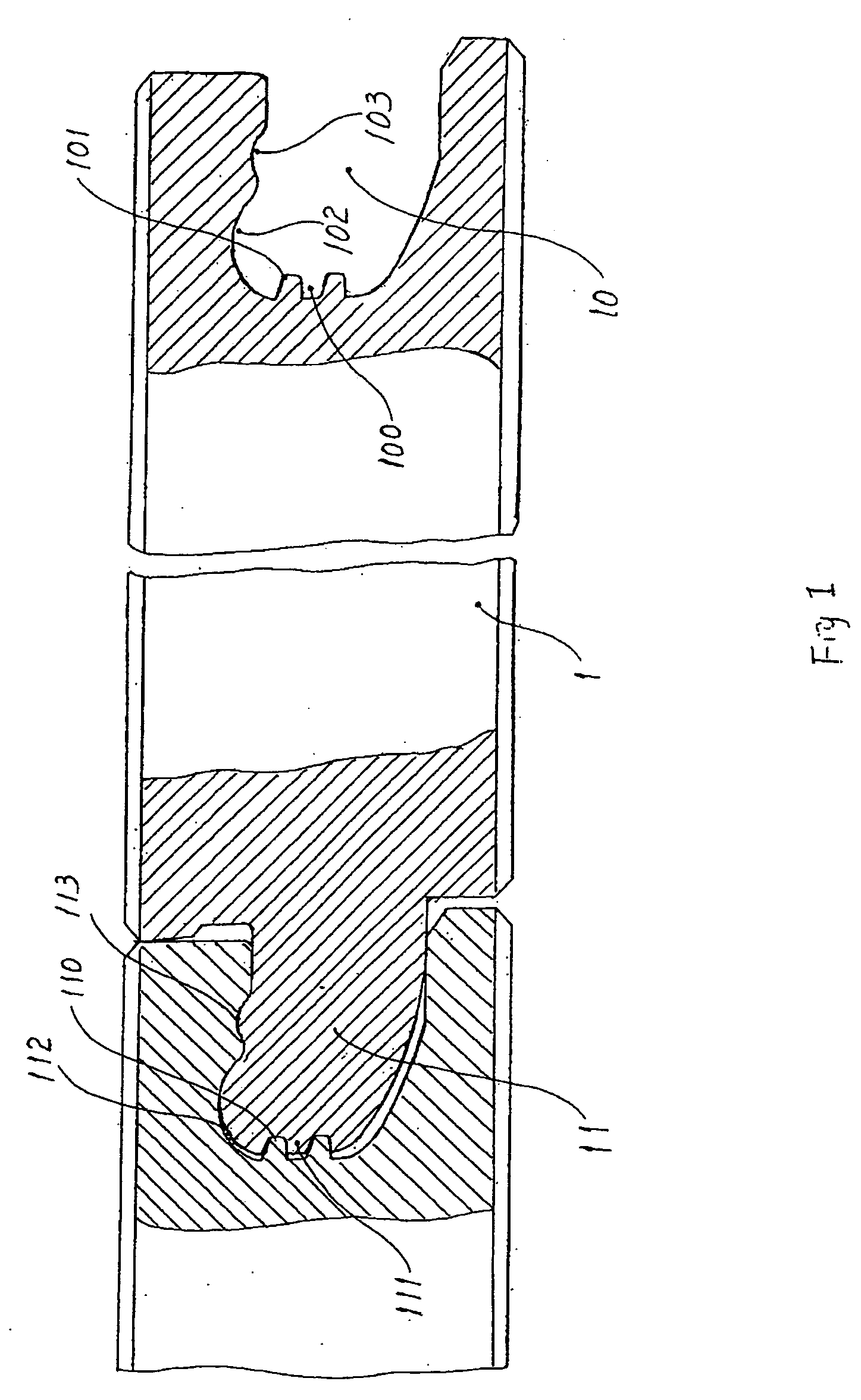

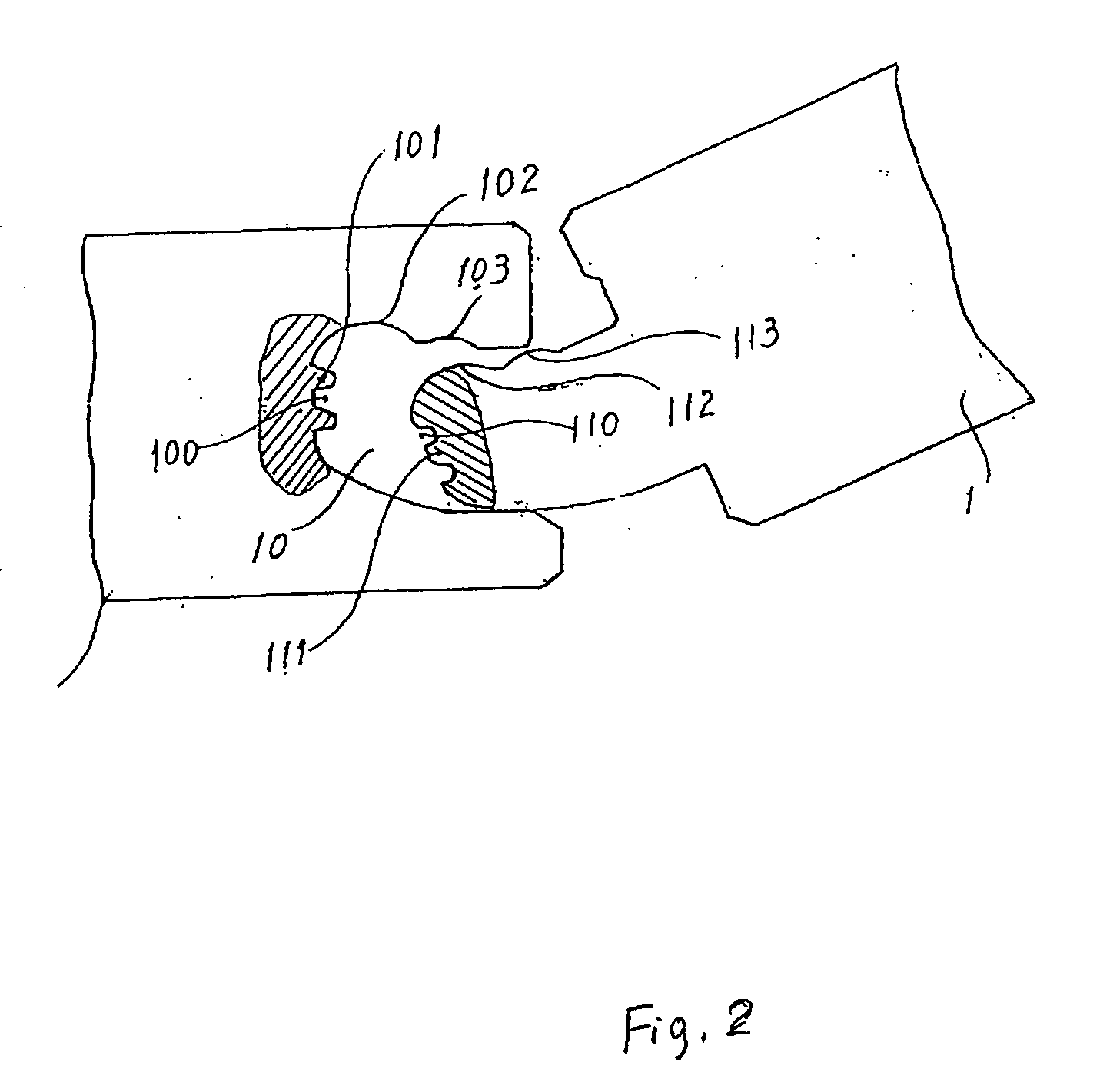

[0009]FIG. 2 is the schematic drawing of the cross-section of assembly of present application used in first embodiment of FIG. 1.

second embodiment

[0010]FIG. 3. is a schematic drawing of the cross-section of the present application.

third embodiment

[0011]FIG. 4. is a schematic drawing of third embodiment of the present application.

DETAILED DESCRIPTION OF THE REFERENCED EMBODIMENTS

[0012] This is the further explanation combine with the accompanying drawings for embodiments. As shown in the accompanying drawings, FIG. 1 and FIG. 2, the flange 11 and recess 10 are made in the both edges of floor panel 1. On the vertical side of flange 11 of floor panel, the tooth (tongue) 111 and the groove 110 positioned both sides of the tooth 111, whose section configuration is trapezia, are made on the suitable place. On the other edge of the floor panel, the groove 100 in trapezia form was made in recess 10 of floor panel to corresponding with tooth (tongue) 111, and the two trapezia shaped tooth 101 to interlock with the trapzia shaped groove (tooth space) 110. To ensure the adjoining of the floor panel are stronger and tighter, the arc shaped hump 112, 113 and the depression 102, 103 are made on the connecting aspect of the flange 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com