Waterproof footwear and method for its production

a technology of waterproof footwear and manufacturing method, applied in the field of footwear, can solve the problems of not always that easy to sew gauze strips without any folds, requiring a certain effort on the two longitudinal sides of gauze strips, and achieve the effect of good waterproofness and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

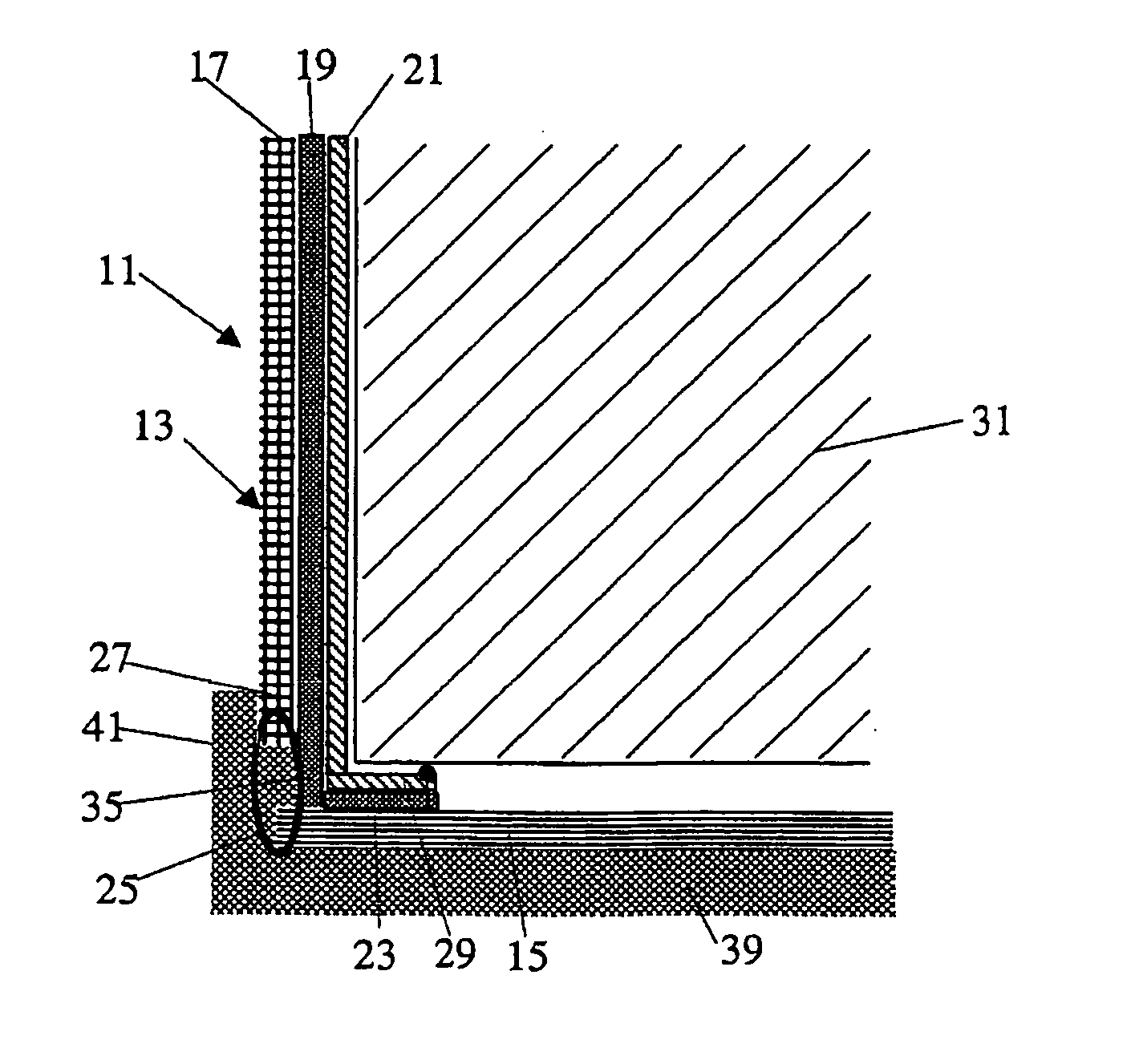

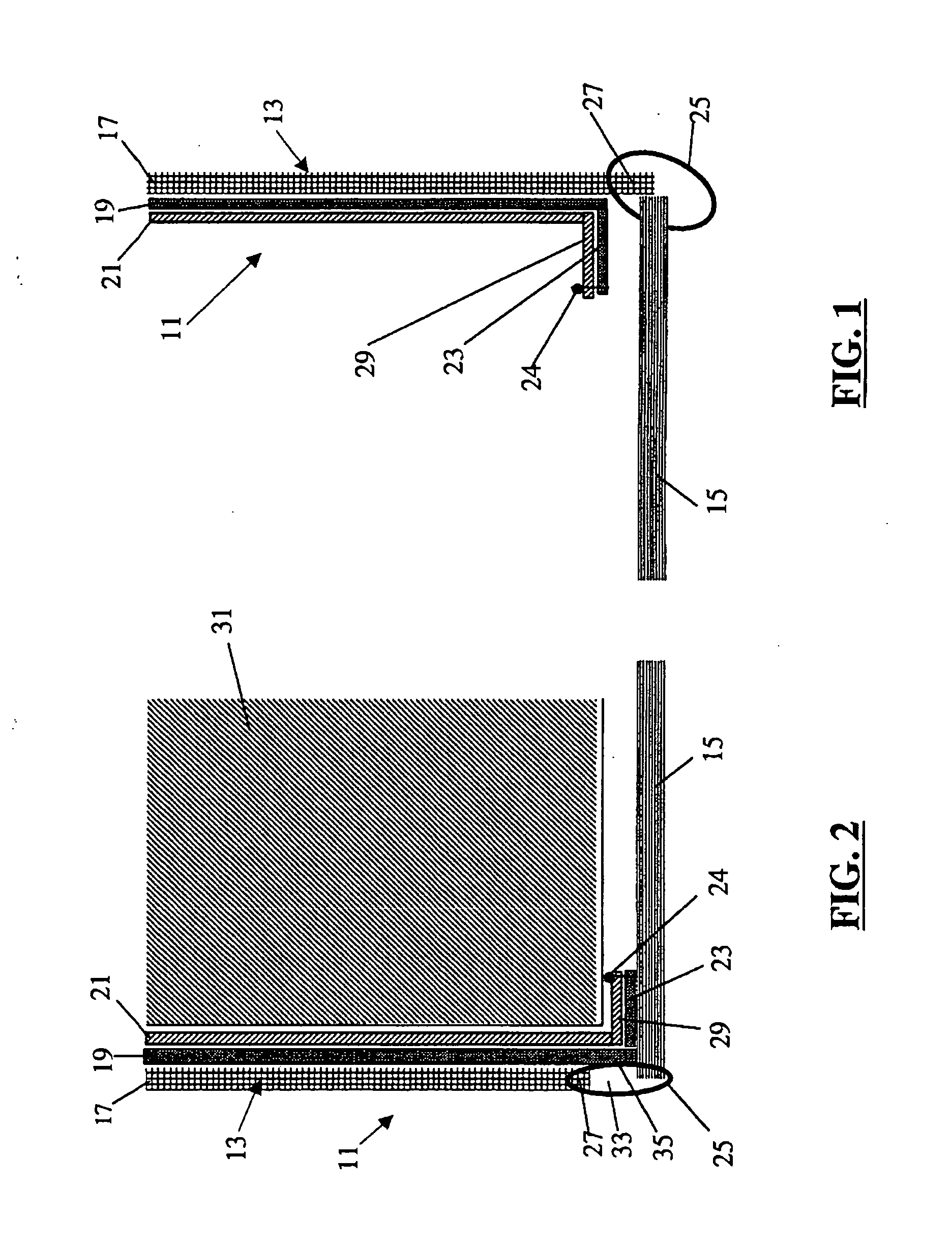

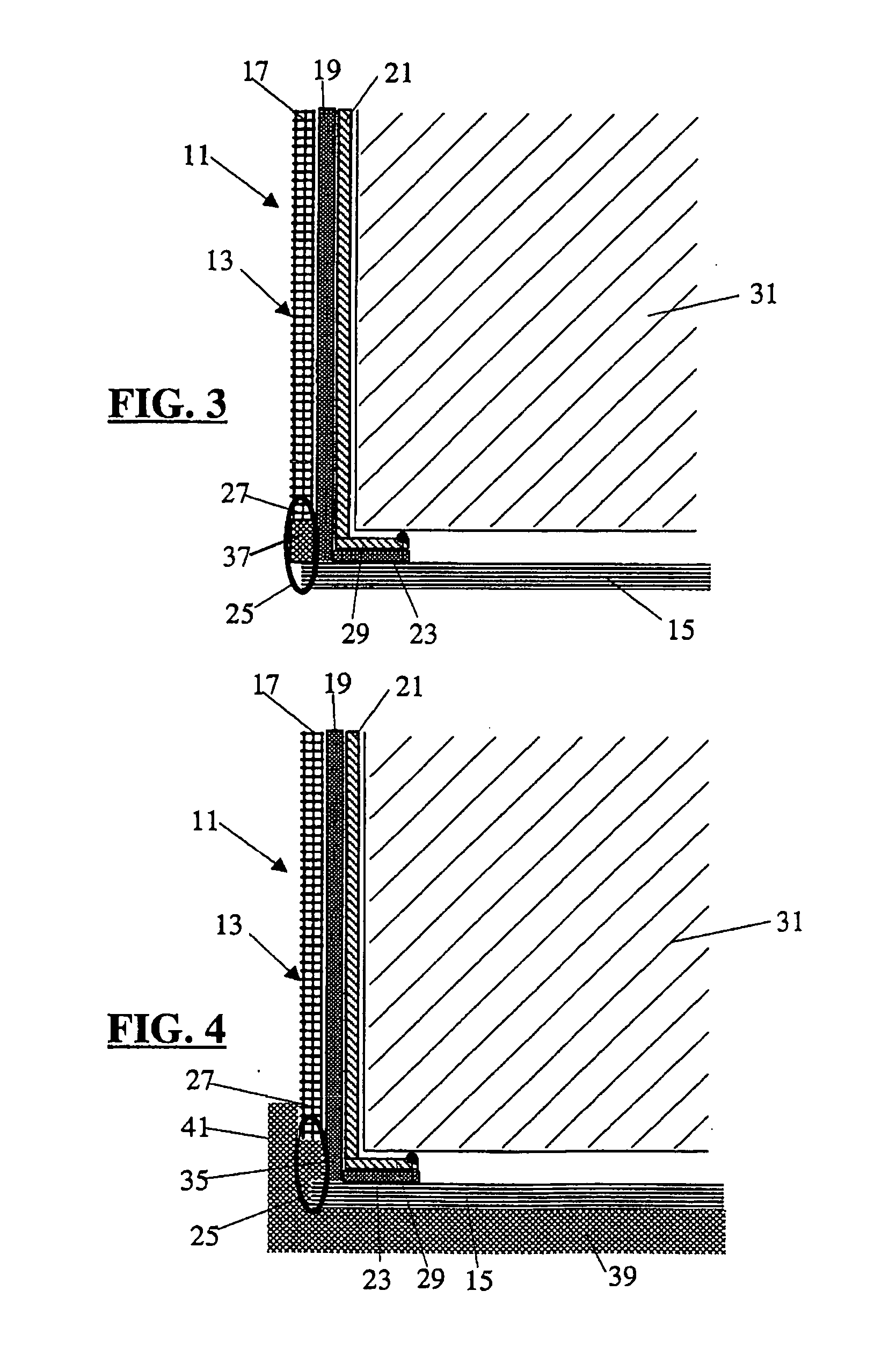

[0062] FIGS. 1 to 4 show the invention, in which a single seam is involved in the joining device. FIGS. 3 and 4 of these embodiments show two different variants of this embodiment, in the case of FIG. 3 the sealing of the functional layer being performed by means of a sealing material, while in the case of FIG. 4 the sealing is performed by means of material of a moulded-on sole. FIGS. 5 to 10 show three further embodiments of the invention, in which two seams are used in the region of the joining device. In the case of the embodiment of FIGS. 7 and 8, as in the case of all the previous embodiments, the lower end of the outer material is joined to an inner sole by means of one loosely sewn or expandable seam of the two seams. In the case of the embodiments shown in FIGS. 9 and 10, between the two seams there is a strip of material which is fastened by means of one of the two seams to the lower end of the outer material and by means of the other of the two seams to the inner sole. In...

fourth embodiment

[0077]FIG. 10 shows a fourth embodiment, which differs very much from the embodiment shown in FIG. 5 and differs from the embodiment shown in FIG. 9 only in that not only the seam 25a joined to the upper border of the strip of material 45 but also the seam 25b joined to the lower border of the strip of material 45 is formed as a loose seam, in that it is loosely sewn and / or sewn with extensible yarn. After the lasting of the shoe in the production stage shown, the two seams 25a and 25b expand, so that two gaps 33a and 33b are created, in the regions of which there are two functional-layer free zones 35a and 35b formed, which can be sealed by sealing material being applied or by liquid sole material penetrating, as already explained in connection with FIGS. 3 and 4.

[0078] In one embodiment of the invention, the joining device, in the embodiments represented in the figures the Strobel seam 25 or the Strobel seams 25, 25a, 25b, 26, runs around the entire lower periphery of the upper. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com