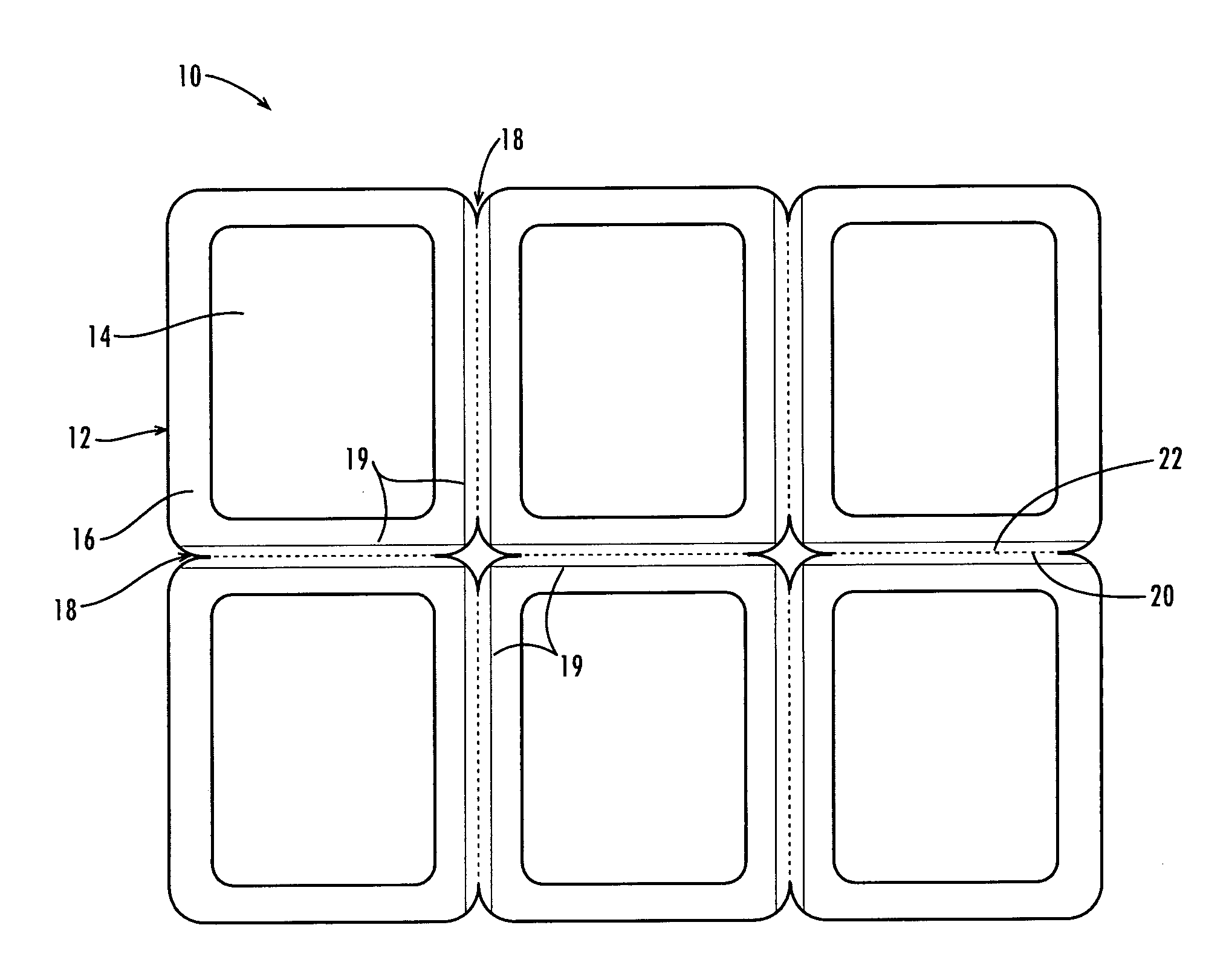

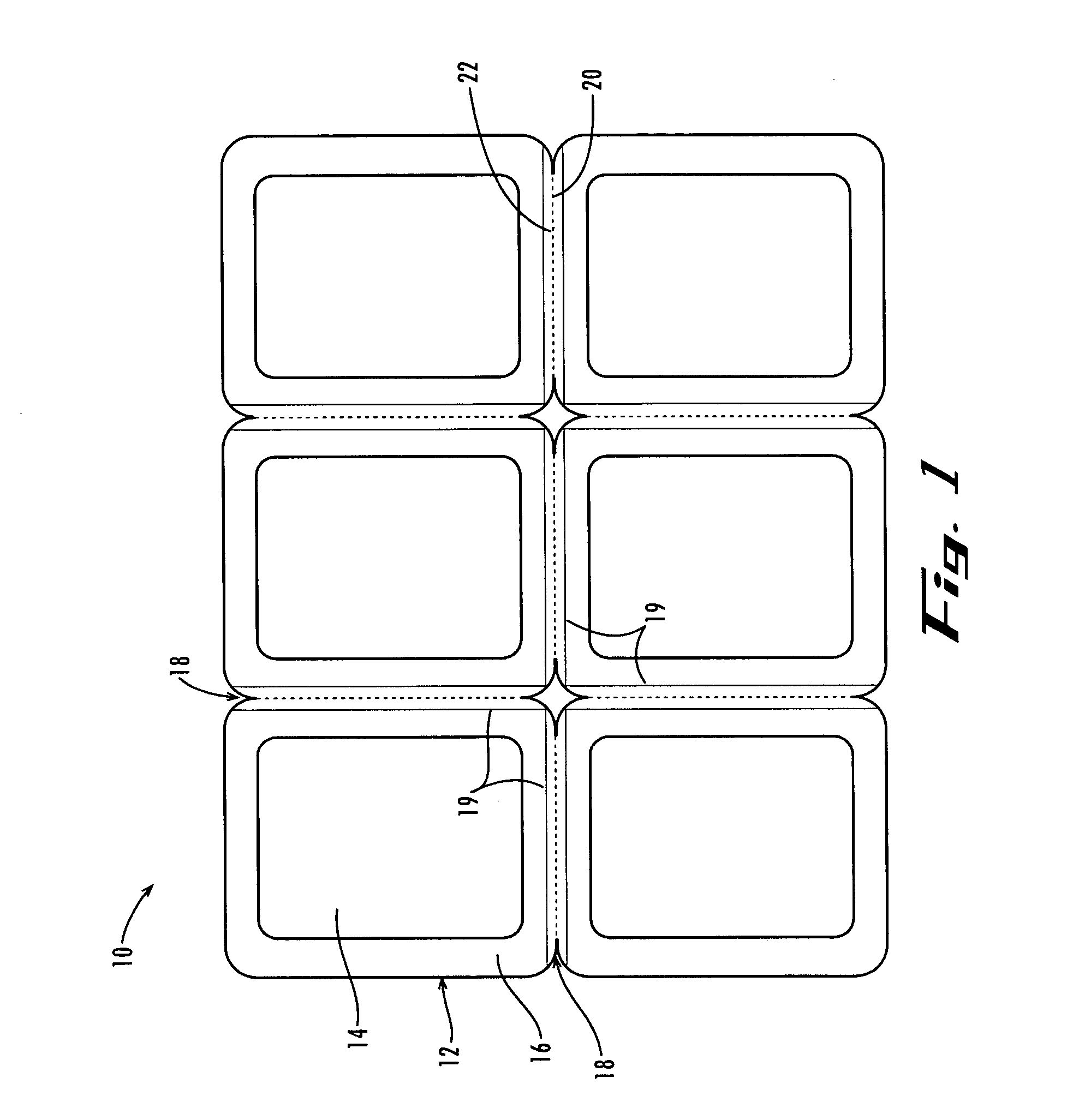

Multiple portion packaging tray and method of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

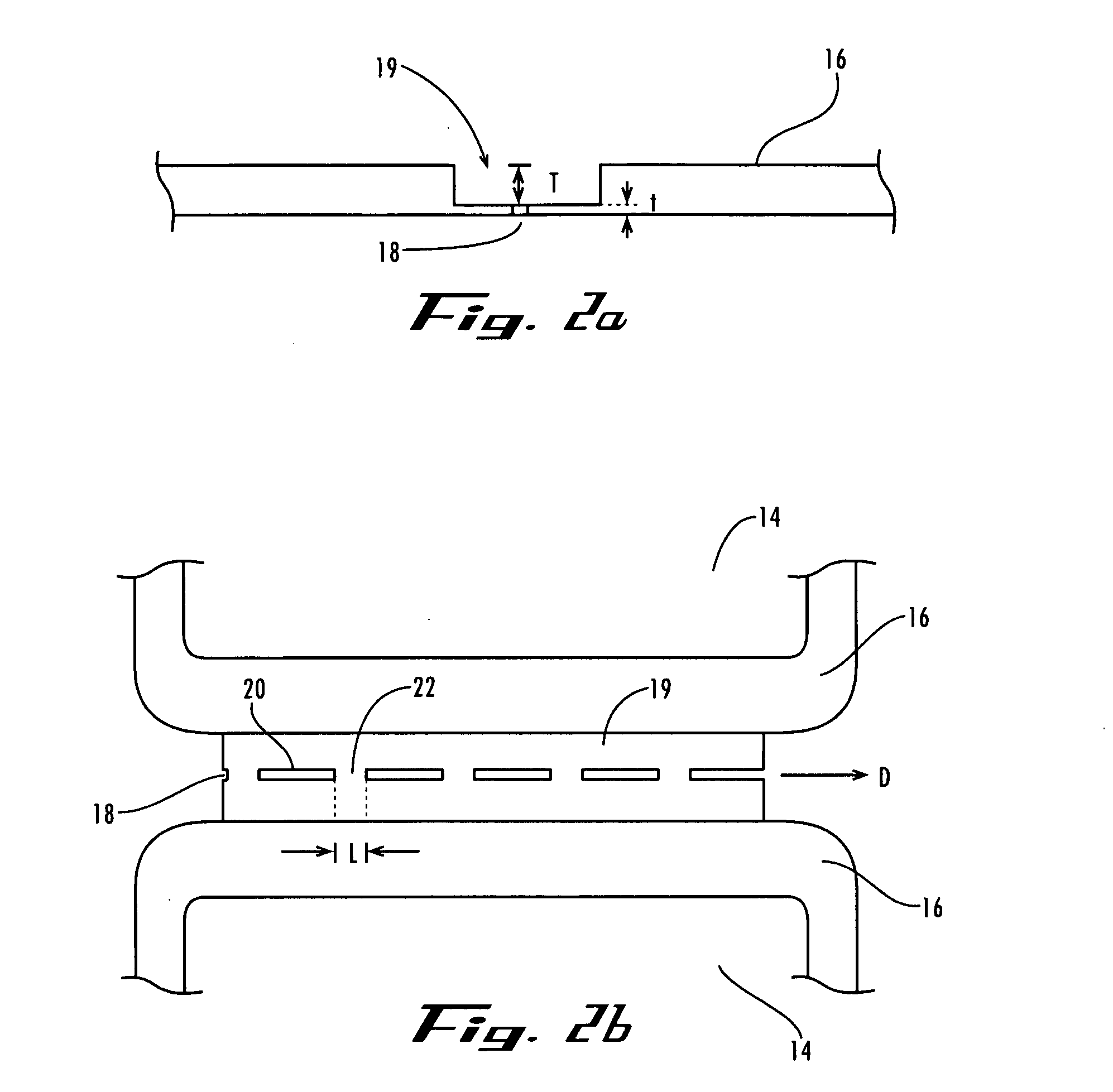

[0022] A 30 mil 100% polypropylene sheet is used to make a multiple portion packaging tray. The polypropylene sheet is heated to 160° C. as it indexes through an oven into the form station at 4 second cycles. In the form station, the hot sheet may be formed using a variety of methods. The formed multiple portion packaging tray leaves the forming station, still attached to the sheet. The formed multiple portion packaging tray enters the trim station approximately 8 seconds after leaving the forming station. At the trim station, a lower platen moves up to the sheet level to capture the individual containers in a die plate. An upper platen containing steel rule knives, notched steel rule knives, and punches moves downward until it just touches the die plate and trims the perimeter of the multiple portion packaging tray as well as forms the tear lines in the flanges with alternating opening and land areas. The notches of the notched steel rule knives are desirably 20 mils in length. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com