Multiple piece bracket assembly for lifting and supporting a structure

a multi-piece bracket and structure technology, applied in the direction of bulkheads/piles, construction, foundation engineering, etc., can solve the problem of reducing the effective bearing contact area between the bracket and the structure, and achieve the effect of facilitating the accurate positioning of various sizes and configurations, maintaining bearing area engagement, and improving ease of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

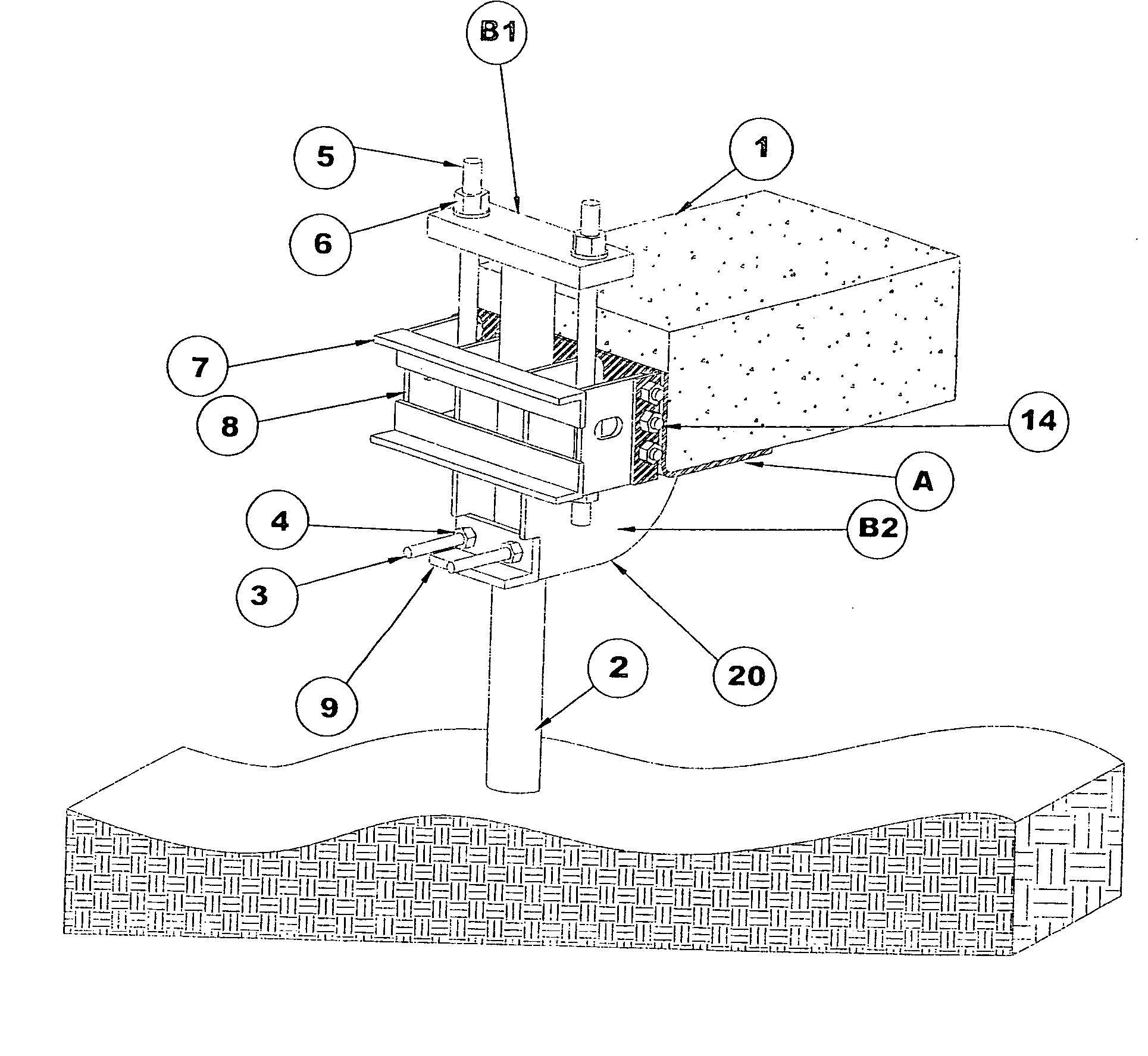

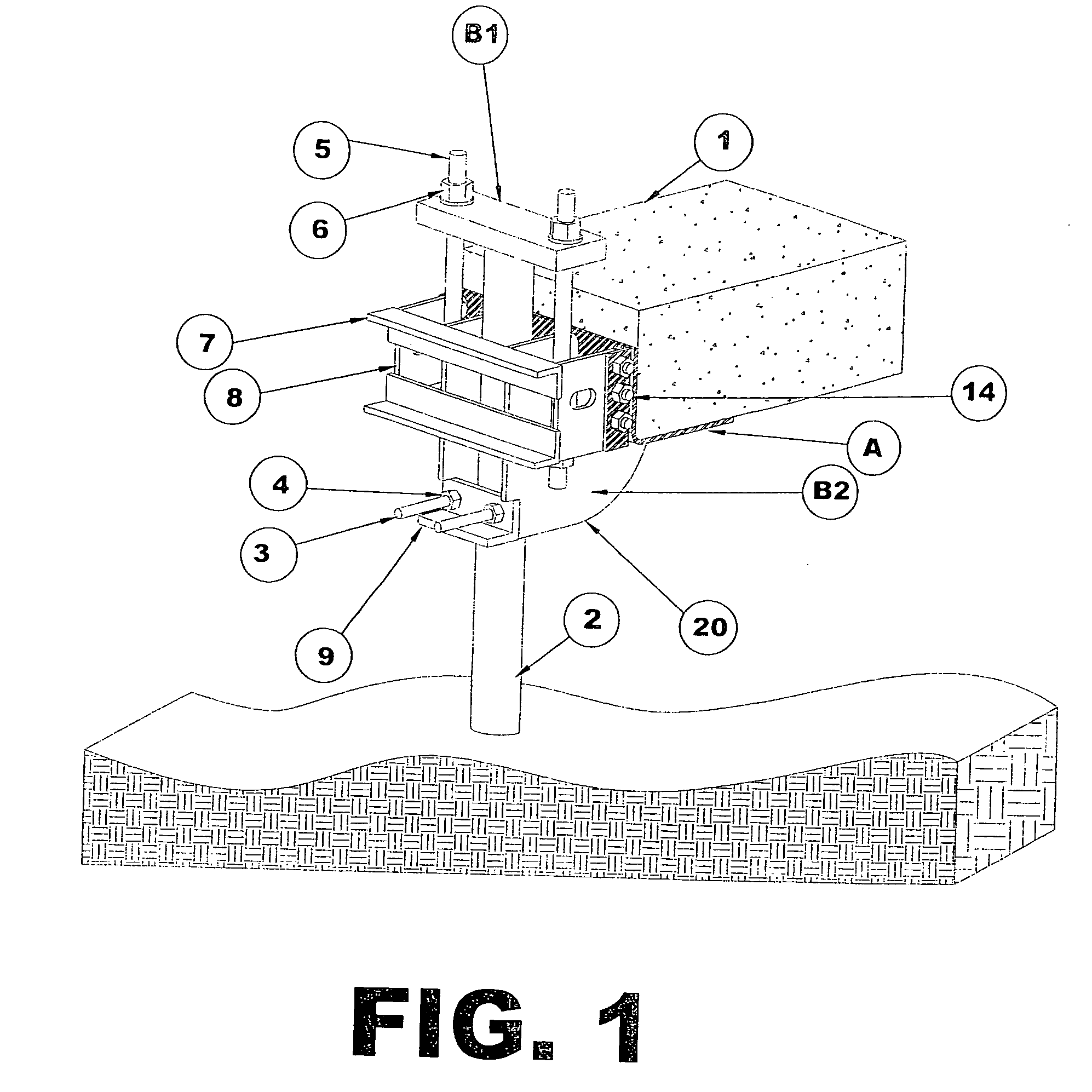

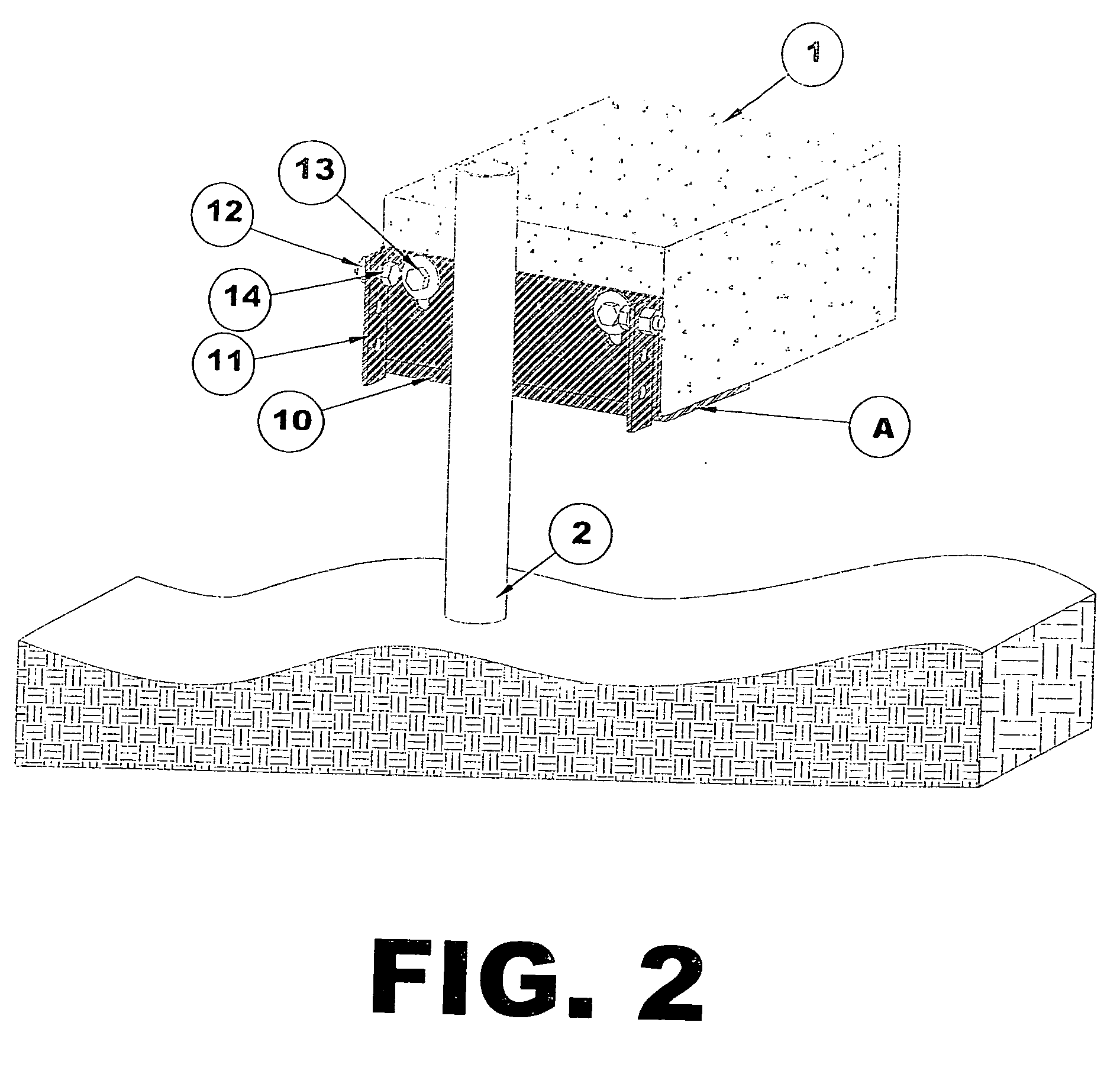

[0029] The present art overcomes the prior art limitations by providing a bracket of the type used in lifting and supporting a structure or shallow foundation element (1) and that can be installed on a pile (2) positioned adjacent to the structure (1); said bracket utilizing a temporary pile guide (C) to help facilitate installation of the pile. Additionally, the bracket incorporates a system to help eliminate horizontal axis rotation of the bracket assembly under load, thereby maintaining adequate bearing surface contact area between the bracket and the structure. These along with other critical features of the current bracket assembly are here presented in detail utilizing the attached sketches FIG. 1 thru FIG. 9. In references to the bracket assembly, ‘back’ refers to the side of the assembly opposite the structure and, ‘front’ refers to the side adjacent to the structure. The call-outs for each component illustrated in the drawings are consistent throughout all ten figures.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com