Golf club head

a club head and golf technology, applied in the field of golf club heads, can solve the problems of affecting the structural strength of the sole portion, the basic structure of the deformation portion is not provided further improvement, etc., and achieve the effect of enhancing the elastic effect and hitting performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

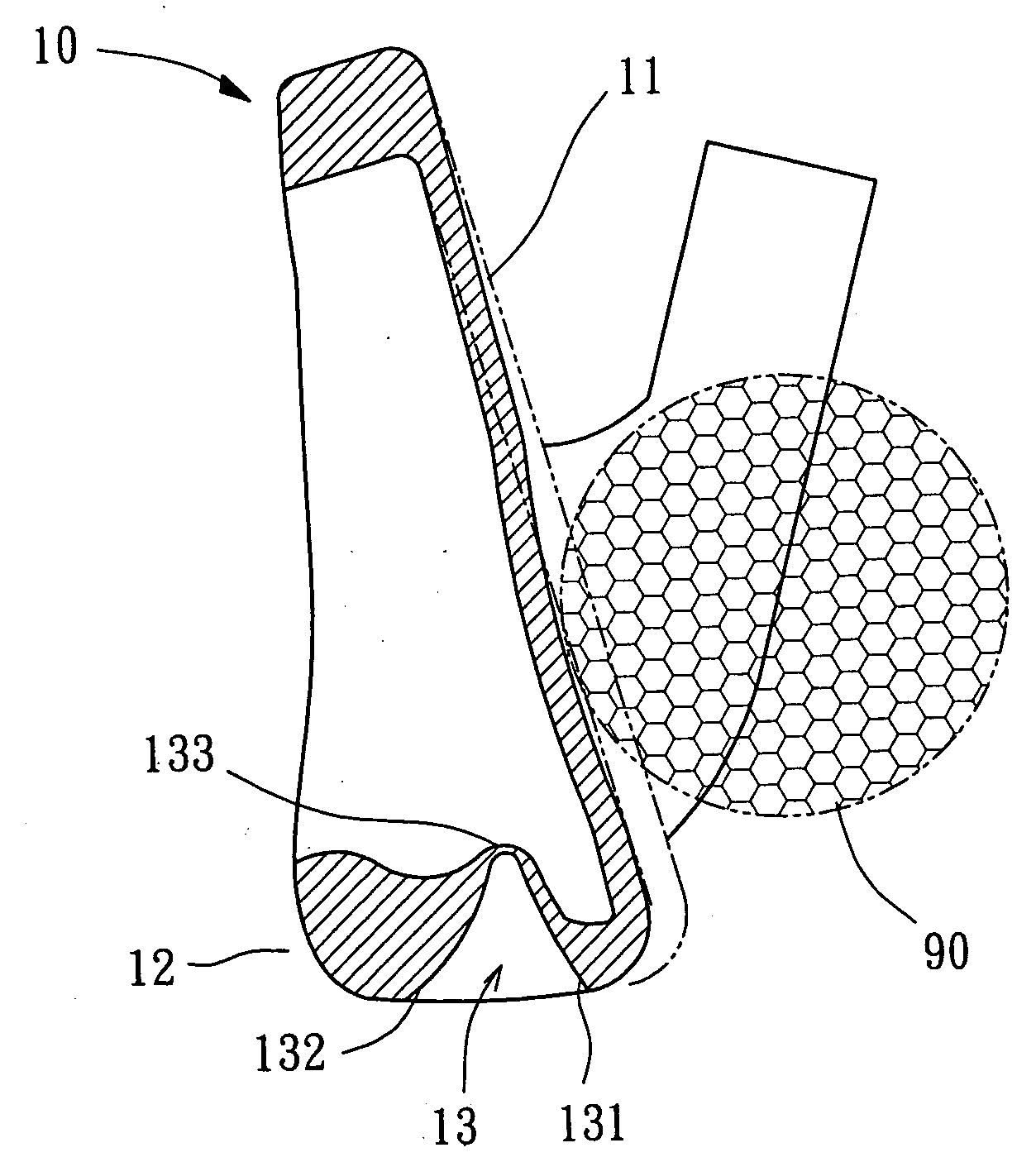

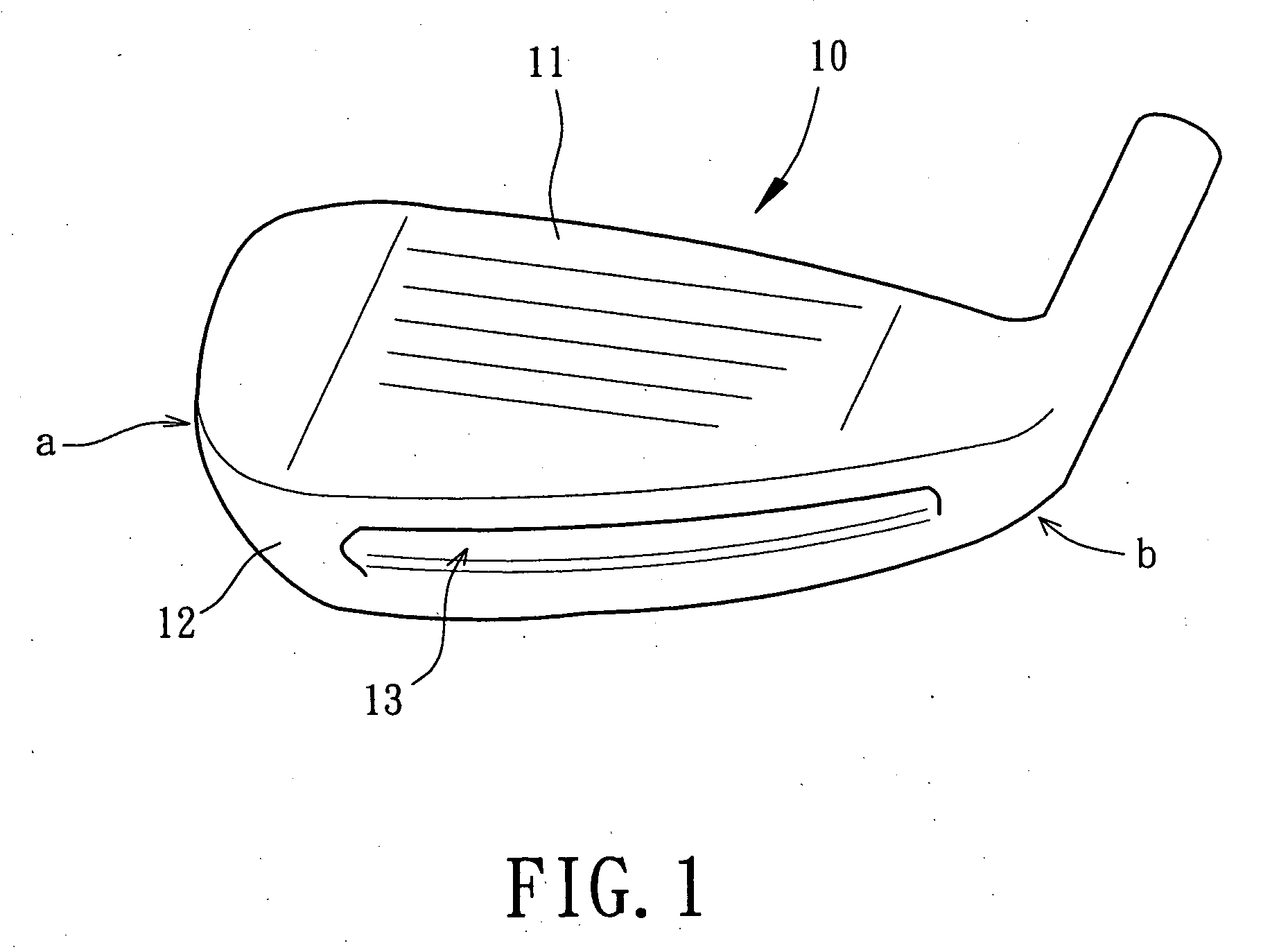

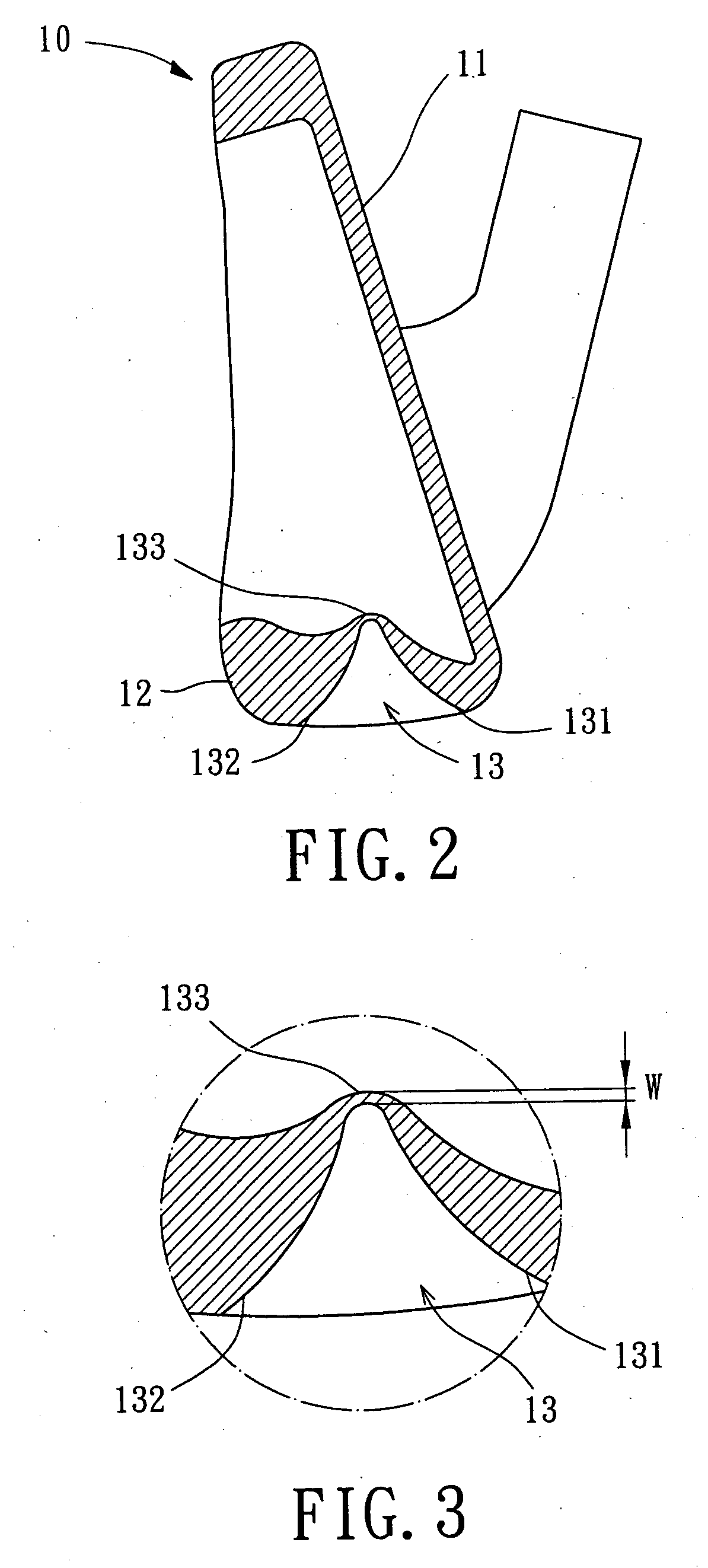

[0028] Referring to FIGS. 1 through 3, a golf club head 10 in accordance with the present invention comprises a face portion 11, a sole portion 12, a toe portion “a” and a heel portion “b”. In the illustrated embodiment, the golf club head is an iron club head made by casting, forging, or mechanical processing. The face portion 11 is disposed on a front face of the golf club head for hitting a golf ball. The sole portion 12 forms a lower portion of the golf club head.

[0029] The sole portion 12 comprises a deformation portion 13. In the illustrated embodiment, the deformation portion 13 is formed on an outer face of the sole portion 12 near the face portion 11, with an inner face of the sole portion 12 protruding upward toward a blade (not labeled) of the golf club head 10. The deformation portion 13 extends from the toe portion “a” to the heel portion “b” of the golf club head 10, providing a structure with enhanced elastic effect.

[0030] The deformation portion 13 comprises a defor...

second embodiment

[0034]FIG. 5 illustrates the invention. In this embodiment, the golf club head 10 is a head of a wood club or utility golf club. Similarly, the sole portion 12 comprises a deformation portion 13 near the face portion 11. The deformation portion 13 extends from the toe portion (not labeled) through the heel portion (not labeled) of the golf club head 10.

[0035] The deformation portion 13 comprises a deformation-starting section 131, a deformation-ending section 132, and a maximum deformation section 133 between the deformation-starting section 131 and the deformation-ending section 132. The thickness of the deformation-starting section 131 and the thickness of the deformation-ending section 132 decrease toward the maximum deformation section 133 so that the maximum deformation section 133 has the smallest thickness. Thus, the elastic deforming capability of the sole portion 12 of the golf club head 10 is increased without sacrificing the structural strength of the sole portion 12. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com