Device for applying adhesive to a workpiece

a technology for workpieces and adhesives, applied in the direction of coatings, programmed manipulators, programme control, etc., can solve the problems of time-consuming and substantial calibration efforts, and achieve the effect of rapid defect recognition and correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

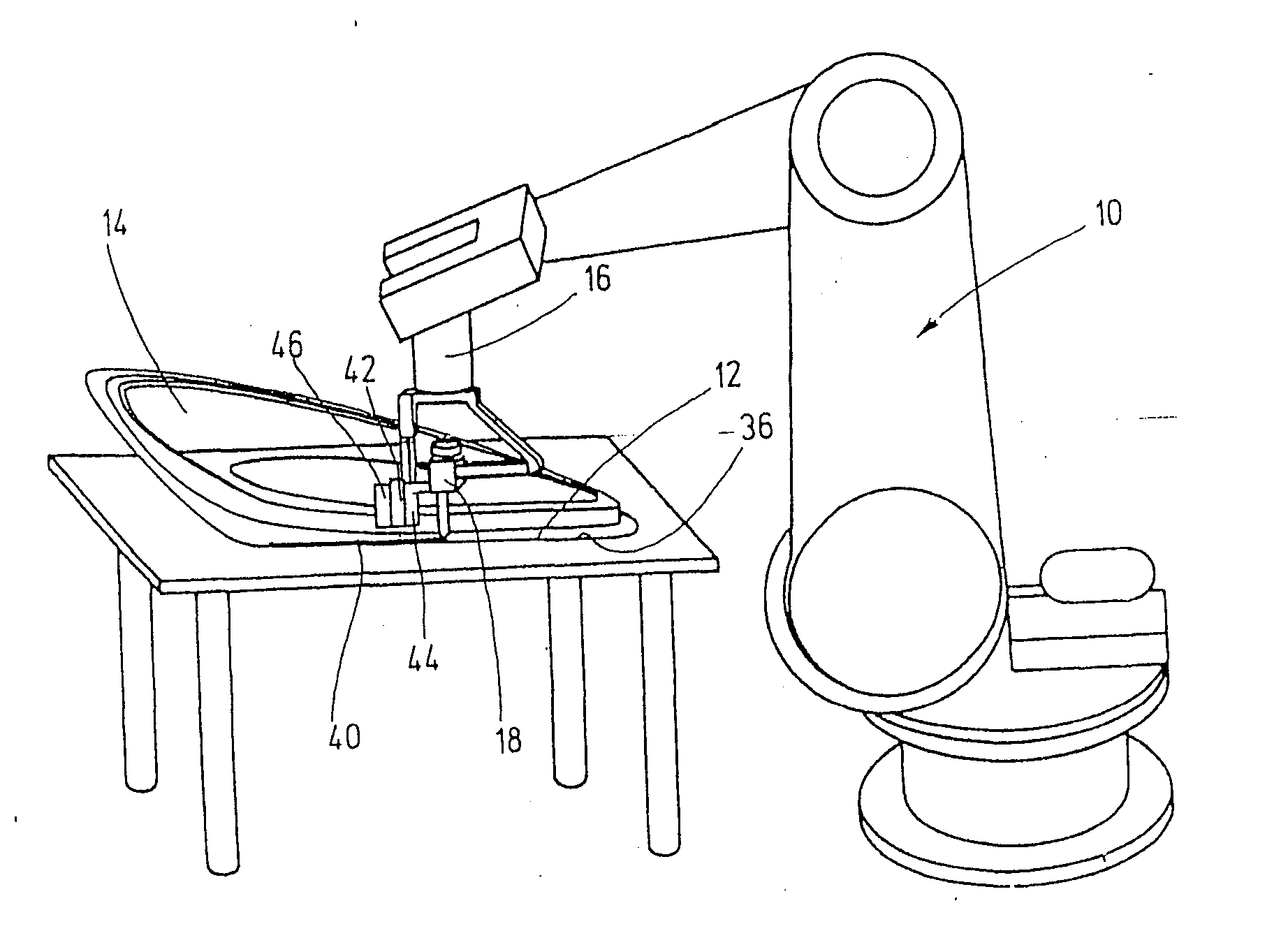

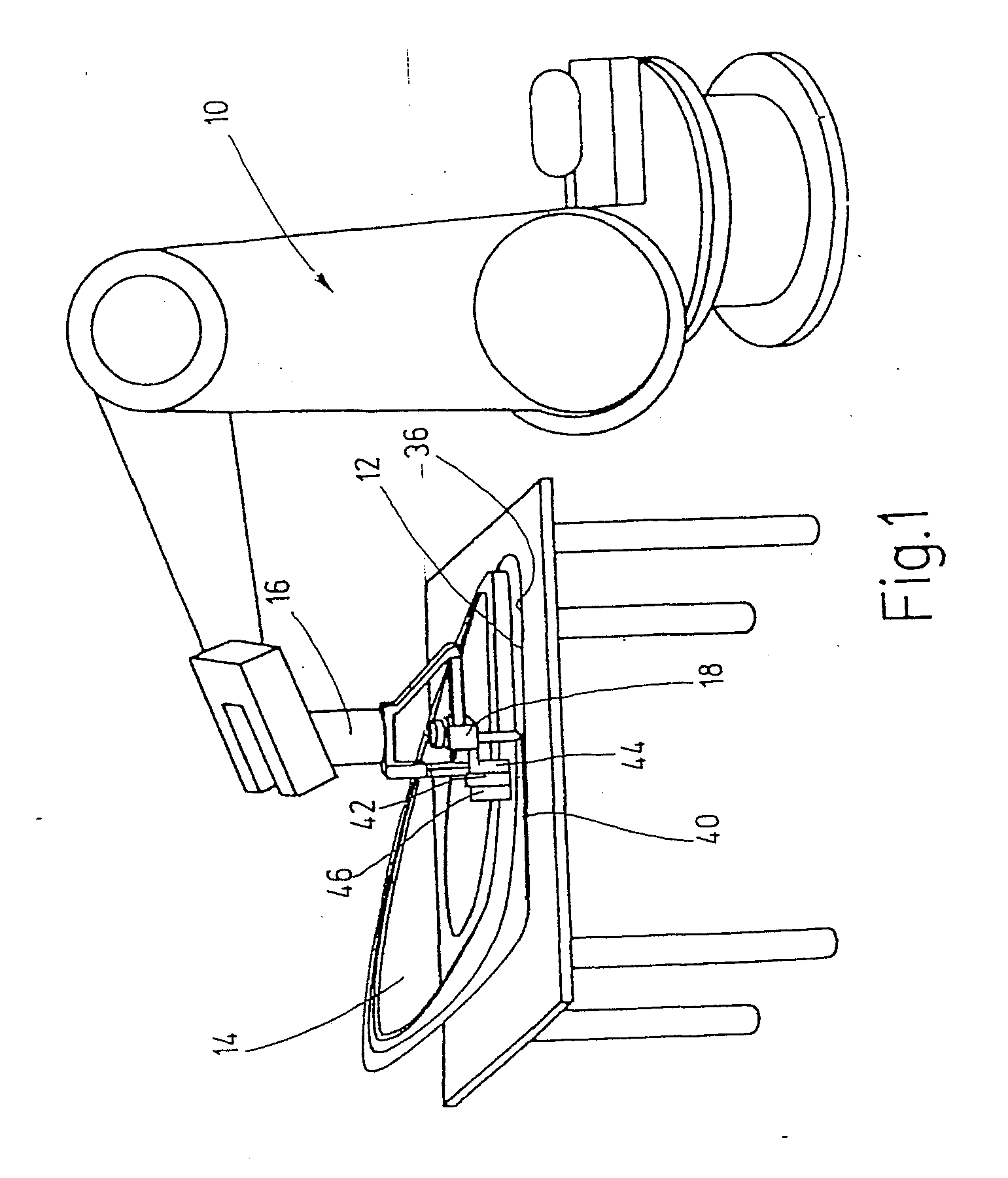

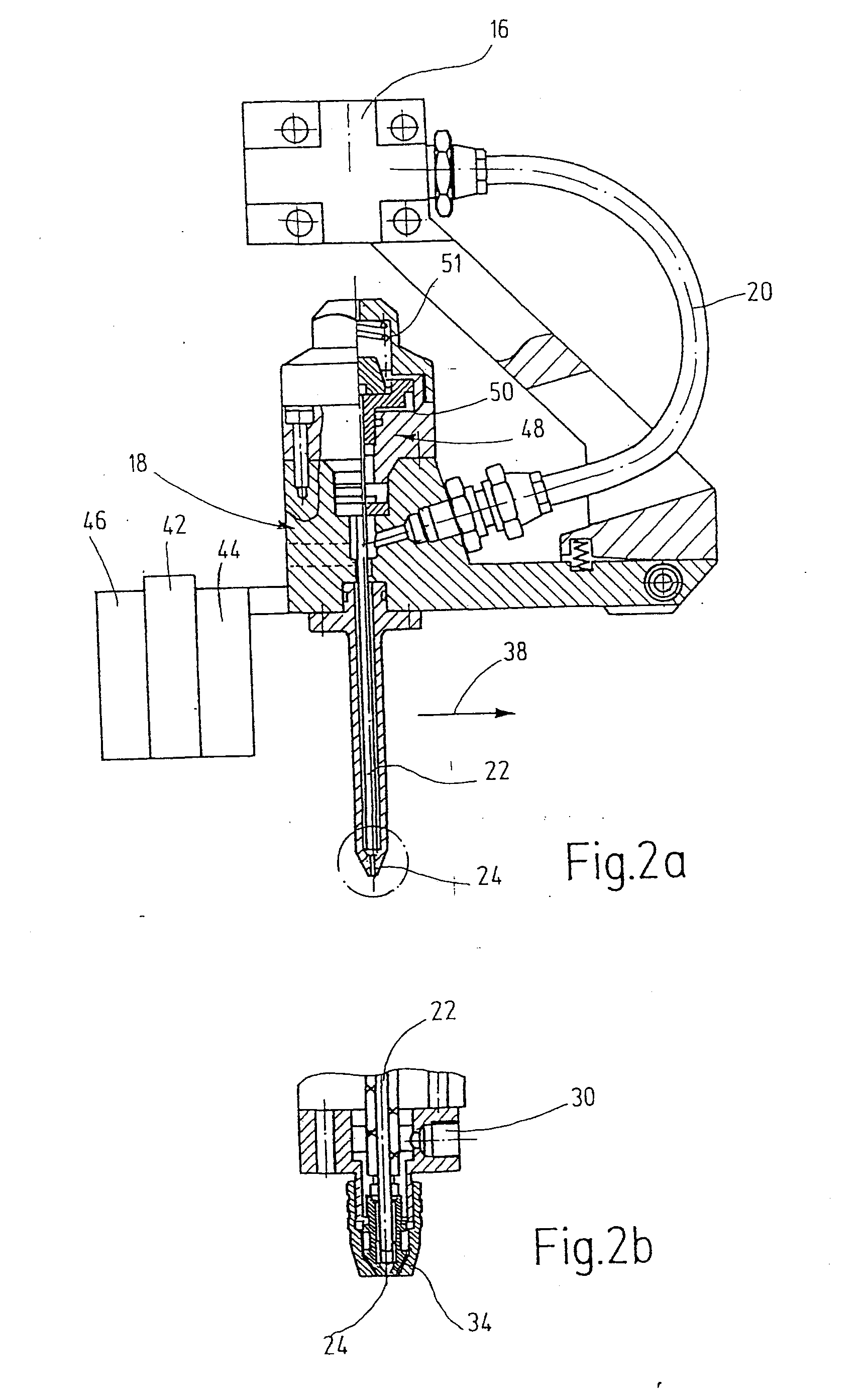

[0022] The robot 10 shown in the figure is designed for application of adhesive for sealing of edge beads or flange welds 12 of workpieces 14, here parts for passenger vehicles. The robot carries for this purpose on its end element 16 a nozzle head 18, which is supplied with a pasty adhesive via a flexible hose 20 and includes an application nozzle 24 closeable via a valve needle 22. The actuation of the valve needle 22 occurs via a cylinder-piston arrangement 48, of which the piston 50, when in the open position, is slid upward pneumatically by the robot control against the force of a closing spring 51, and in the closed position is slid downward under the influence of the closing spring 51. In the shown embodiment the nozzle head 18 is a cyclone spray head, wherein the adhesive thread 28 is emitted out of the application nozzle 24, which thread is deflected and whirled with the aid of pressurized gas, such that a strip-like laid-down partially open adhesive strip 40 of defined bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com