Double pivot vehicle mirror assembly

a mirror and double-pitch technology, applied in the field of mirror assemblies, can solve the problems of high cost of simultaneous attaining a fixed position, and achieve the effect of small support force, enhanced support arm and/or mirror head, and high resistance torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

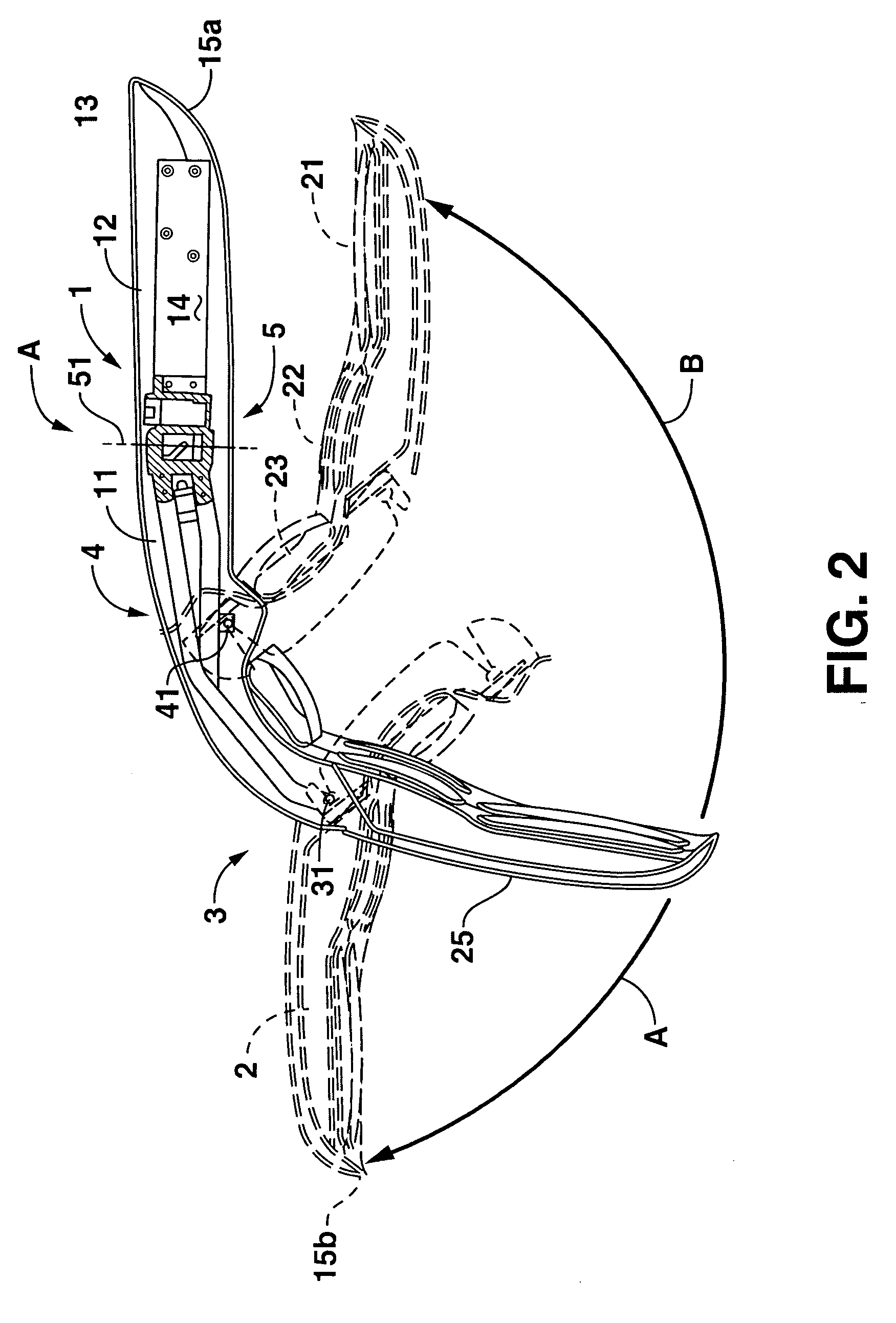

[0020] Referring now in more detail to the drawings, the invention will now be described in more detail.

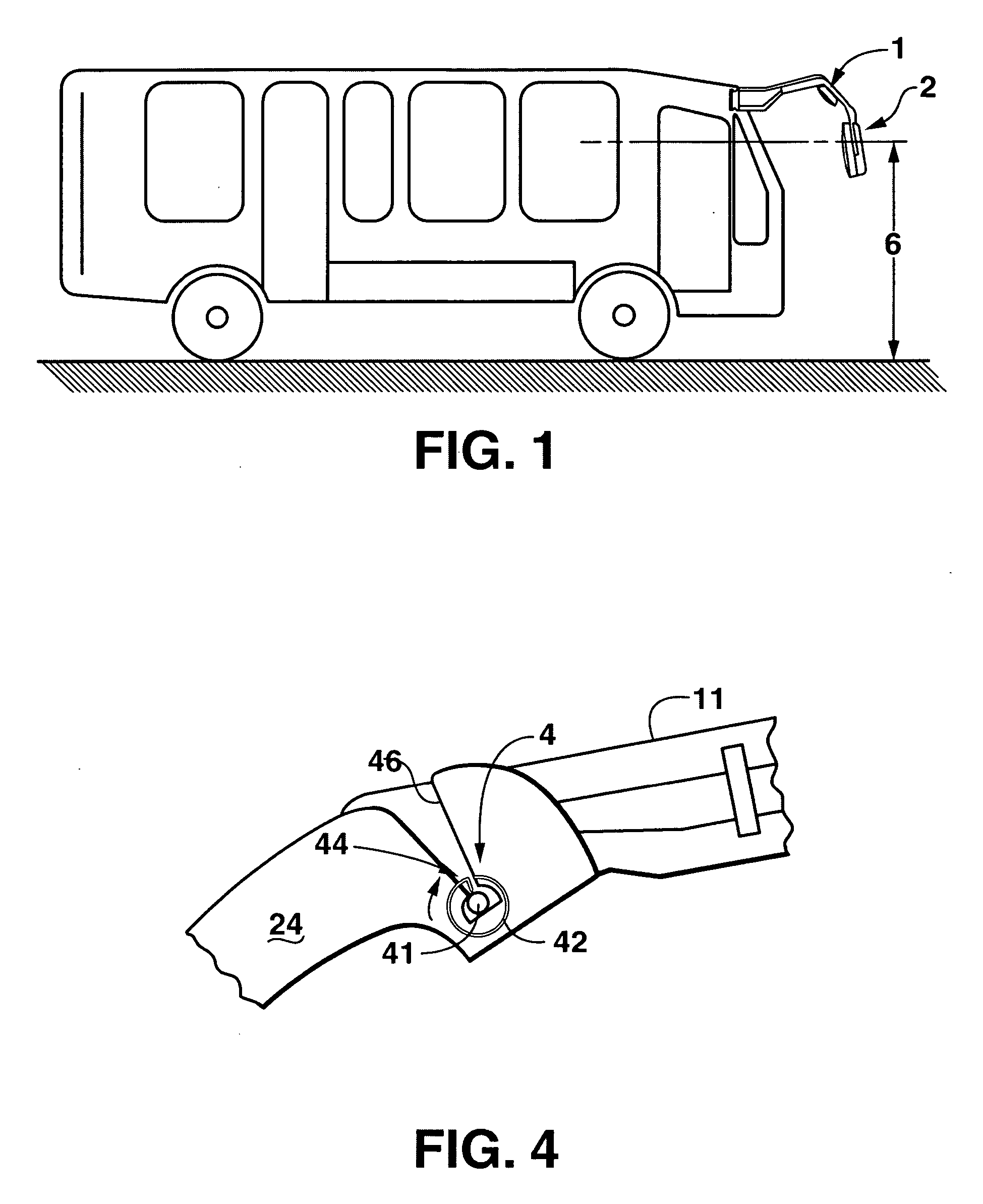

[0021] As is shown in FIG. 1, a mirror assembly, designated generally as A, in accord with the present invention is illustrated installed on a vehicle. The mirror assembly includes a support arm 1 and a mirror head 2. Mirror head 2 of the assembly, is illustrated in a position which has not been pivoted, and at least partially extends into safety zone 6 above the ground. Since mirror head 2, in accordance with the invention, is pivotal in alternate positions above the safety zone, damage is avoided even in the case of an impact against an obstruction within the safety zone. Especially traumatic damage to persons, who are within the said safety zone, such as, bus passengers, can be avoided.

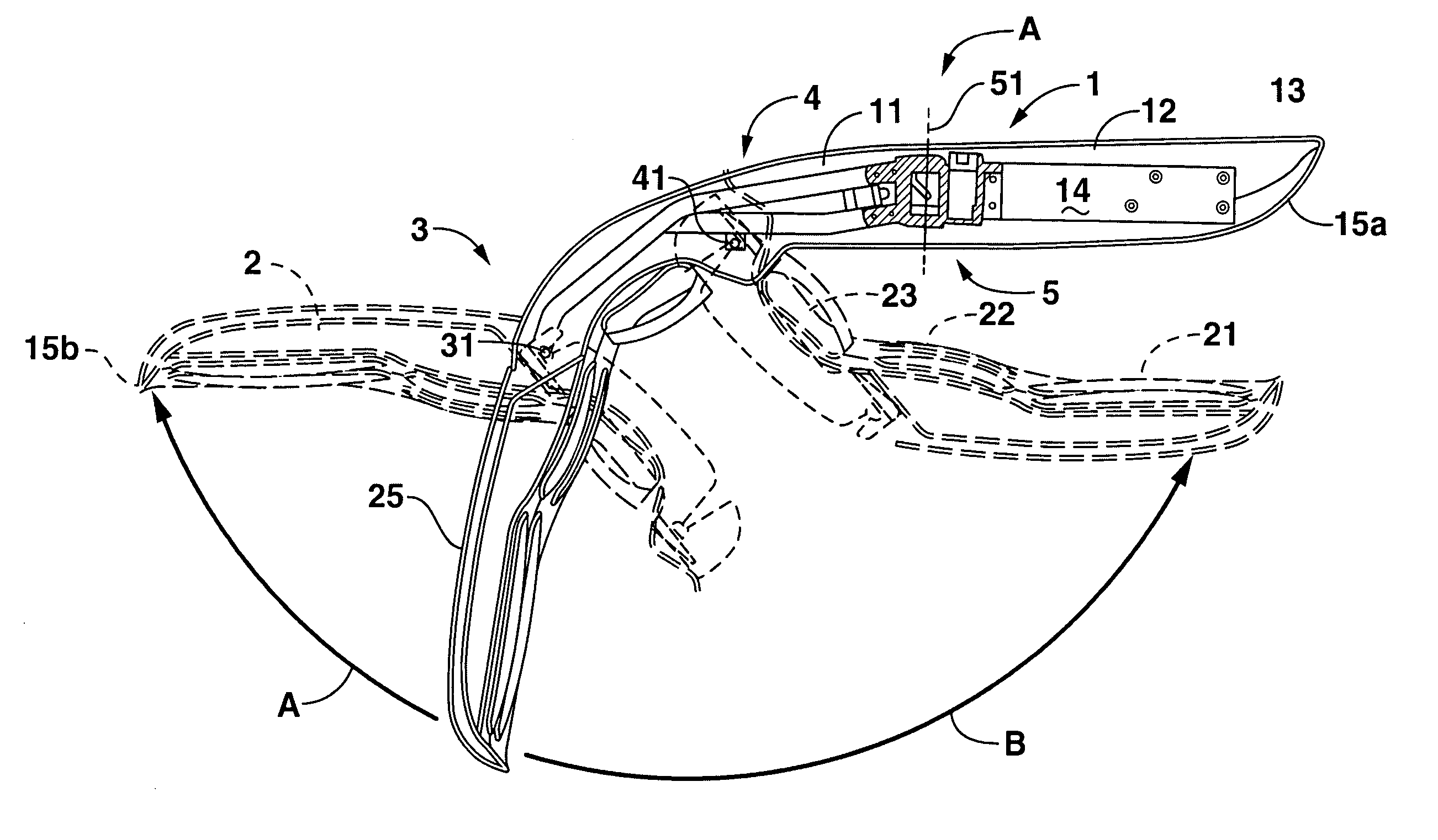

[0022]FIG. 2 illustrates, in a side profile view, a mirror assembly in accordance with an embodiment of the present invention in an operating condition (solid lines) and two alternate positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com