Dish receiving member of dishwasher

a technology for dishwashers and dish racks, which is applied in the field of dishwashers, can solve the problems of inefficient utilization of space in the dish rack, inability to accommodate the desired number of tableware products, and inability to efficiently use the space of the dish rack, so as to achieve efficient utilization of space and efficient utilization of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

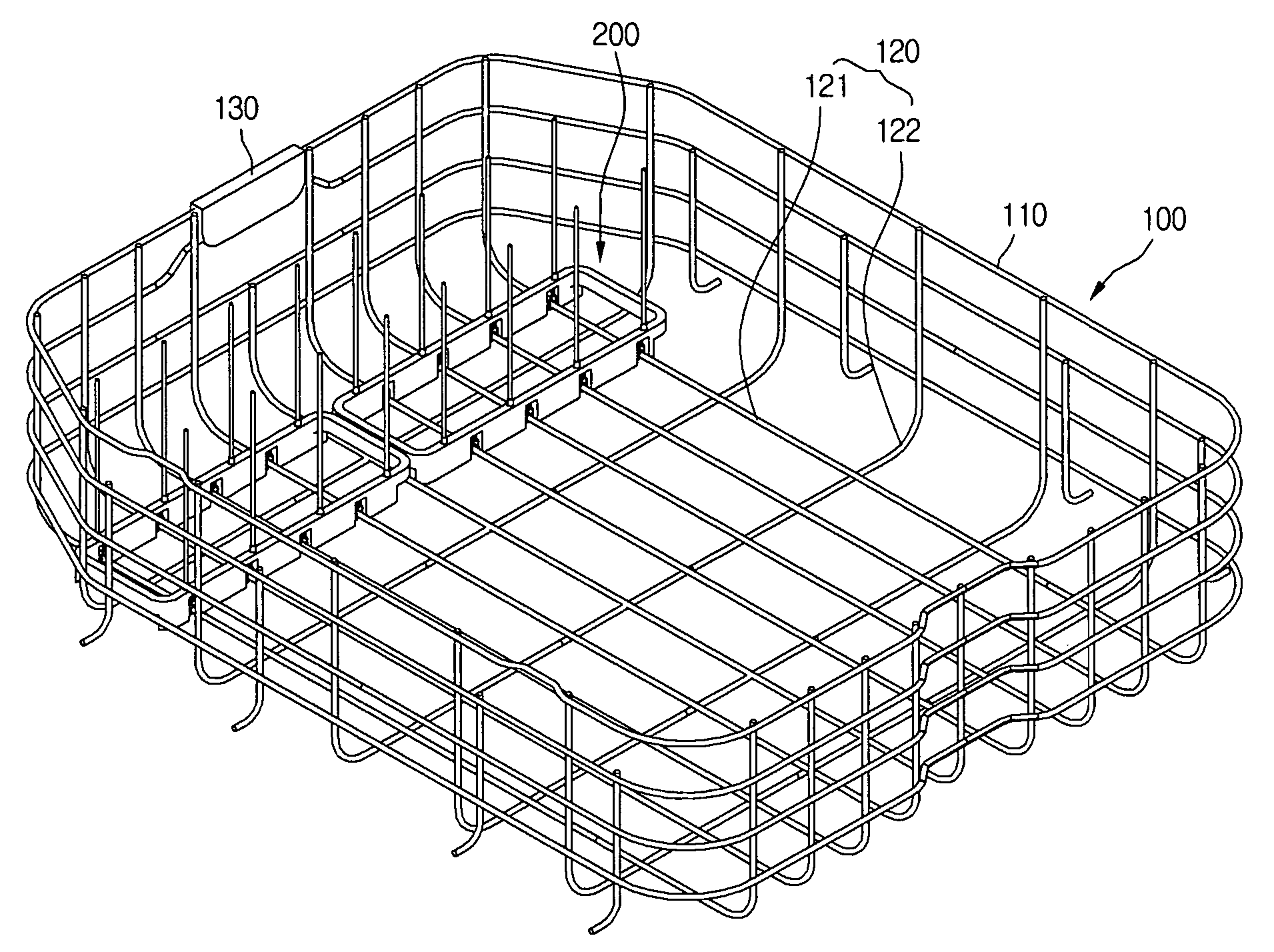

[0027]FIG. 1 is a perspective view of a dish rack 100 provided with a dish receiving member 200 according to the present invention.

[0028] Referring to FIG. 1, the dish rack 100 provided with the dish receiving member 200 includes an outer frame 110 forming the exterior of the dish rack 100, an accommodation frame 120 forming a bottom surface of the dish rack 100, and a grip 130. The accommodation frame 120 is curved in a U shape, and both ends of the accommodation frame 120 are coupled with the outer frame 110. The grip 130 is formed on a front portion or a top portion of the outer frame 110 for a user to pull or push the dish rack 100.

[0029] In detail, the outer frame 110 includes a plurality of horizontally-spaced bars. The accommodation frame 120 includes a plurality of bars that are uniformly spaced inside the outer frame 110. The accommodation frame 120 includes a rack column frame 121 and a rack row frame 122. The rack column frame 121 has one end coupled to a front portion o...

second embodiment

[0051]FIG. 4 is a perspective view of a dish receiving member according to the present invention.

[0052] In the second embodiment of the present invention, the supporting parts are detachably coupled to the holder body.

[0053] Referring to FIG. 4, the dish receiving member 200 includes a holder body 210 and supporting parts 220 extending from a top side of the holder body 210. The holder body 210 includes one or more frame inserting grooves 211 in a bottom surface for fitting around the rack column frame 121 of the accommodation frame 120.

[0054] The holder body 210 further includes supporting part insertion grooves 215 in a top portion for receiving the supporting parts 220. The supporting part insertion grooves 215 have a size and shape corresponding to the supporting parts 220. The supporting part insertion grooves 215 are formed in long surfaces of the holder body 210 at a uniform interval.

[0055] Therefore, the supporting parts 220 can be detachably coupled to the holder body 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com