Corrugated pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

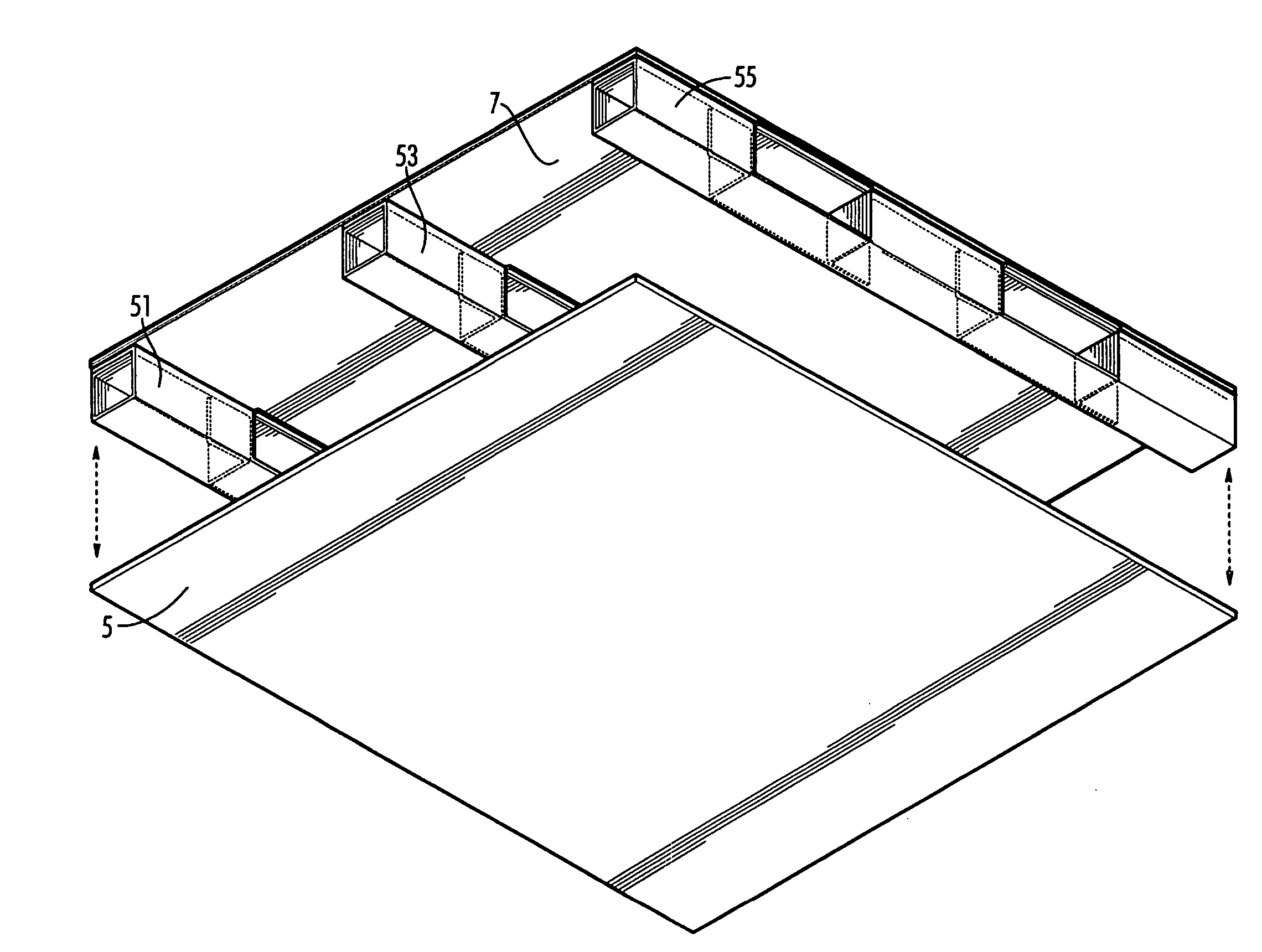

[0018] The pallet of this invention is constructed from standard corrugated paper and may use single or multiple thickness corrugated either coated or uncoated. The rating of the corrugated sheets may be the same or different but would be selected for specific types of use and standardized for that use. Unlike wood, corrugated is readily treated to impart resistance to water, moisture, grease and oil, and made flame retardant. This allows even smaller orders to be prepared for specific shipping conditions without need for ovens or pressure treatment equipment. For international shipment, no fumigation is required and the pallets weight less than equivalent wood pallets.

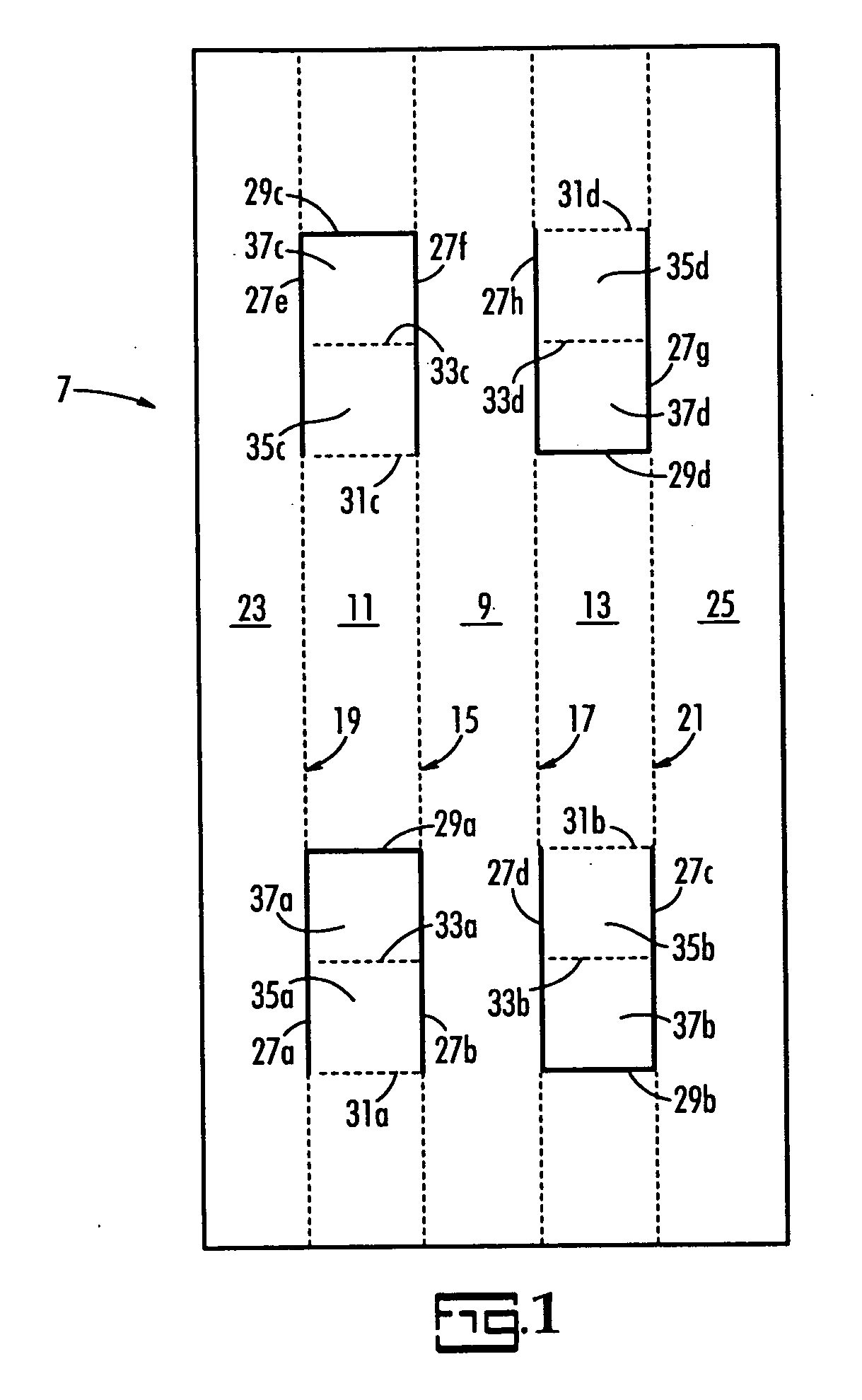

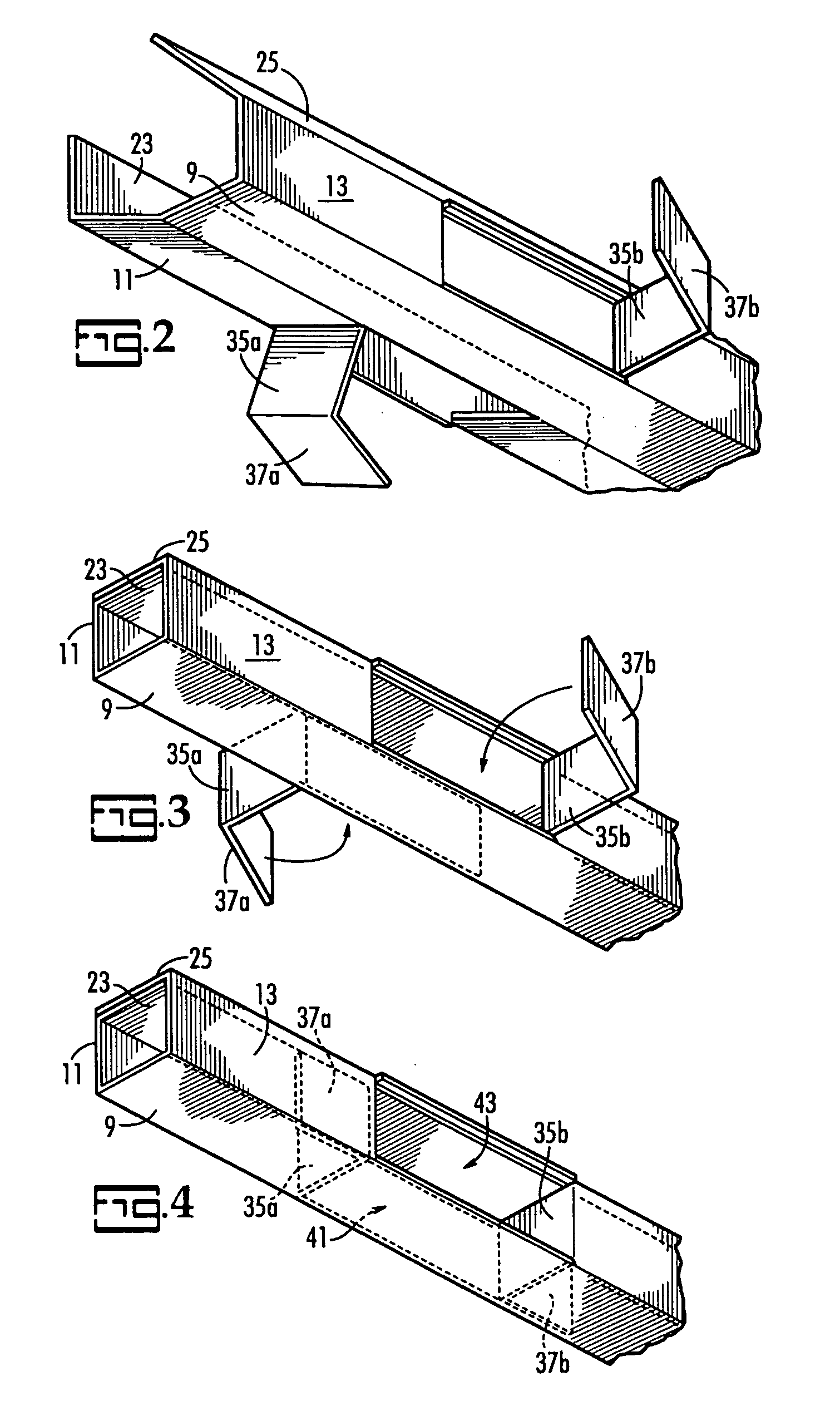

[0019] The pallet is made from three die cut corrugated sheets. One is a top surface which is a flat sheet having the final length and width dimensions of the pallet. The second is the bottom sheet, identical in length and width to the top sheet but which may be a single layer when the top is two or more layers.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com