Buckle with strap securing bar

a technology of securing bar and buckle, which is applied in the direction of buckle, snap fastener, transportation and packaging, etc., can solve the problems of unexpected belt loosening, difficult to loosen the belt when, and requires extra work on the part of the user to loosen the belt, so as to prevent inadvertent strap slippage and easy loosen the strap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

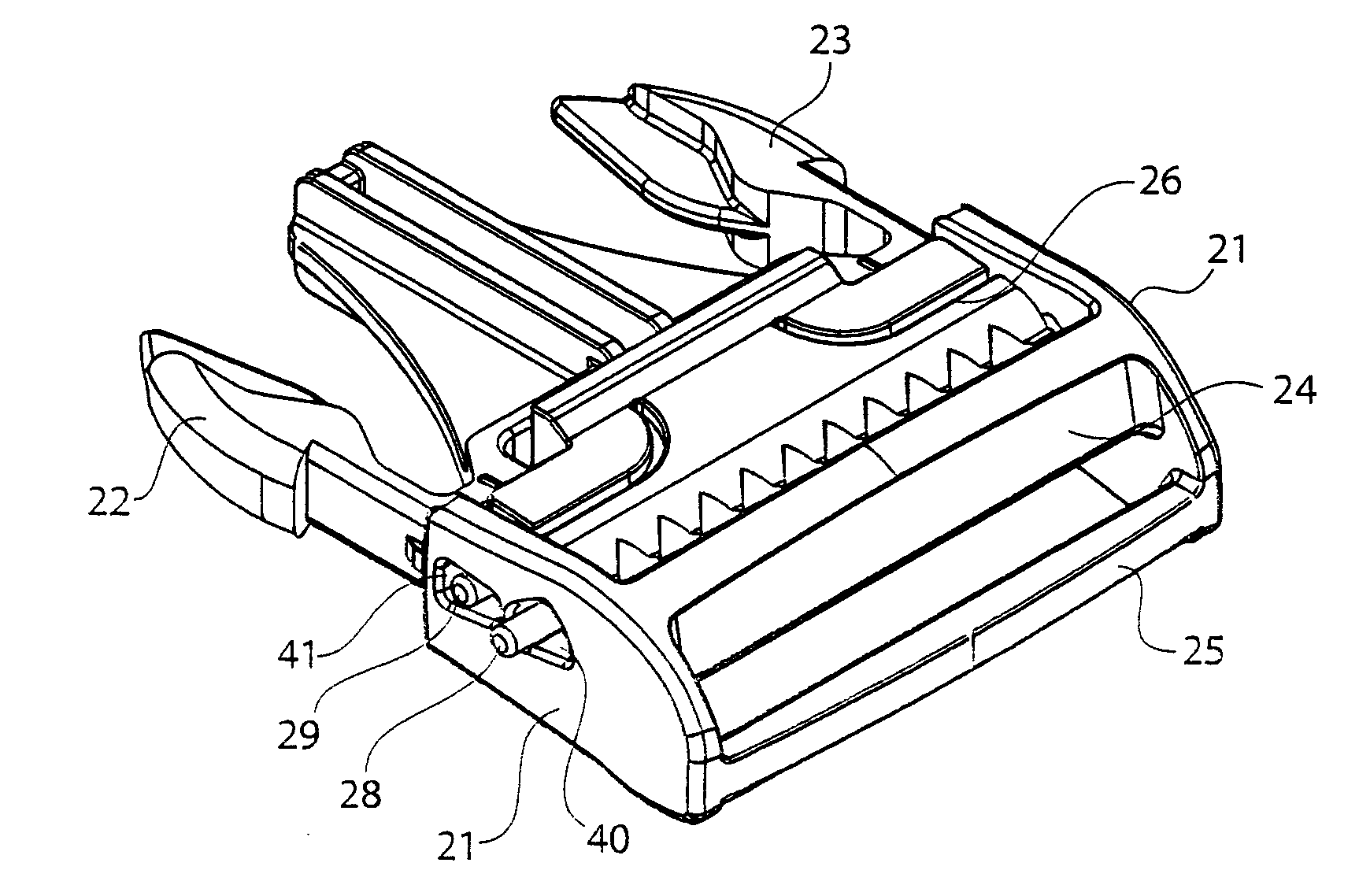

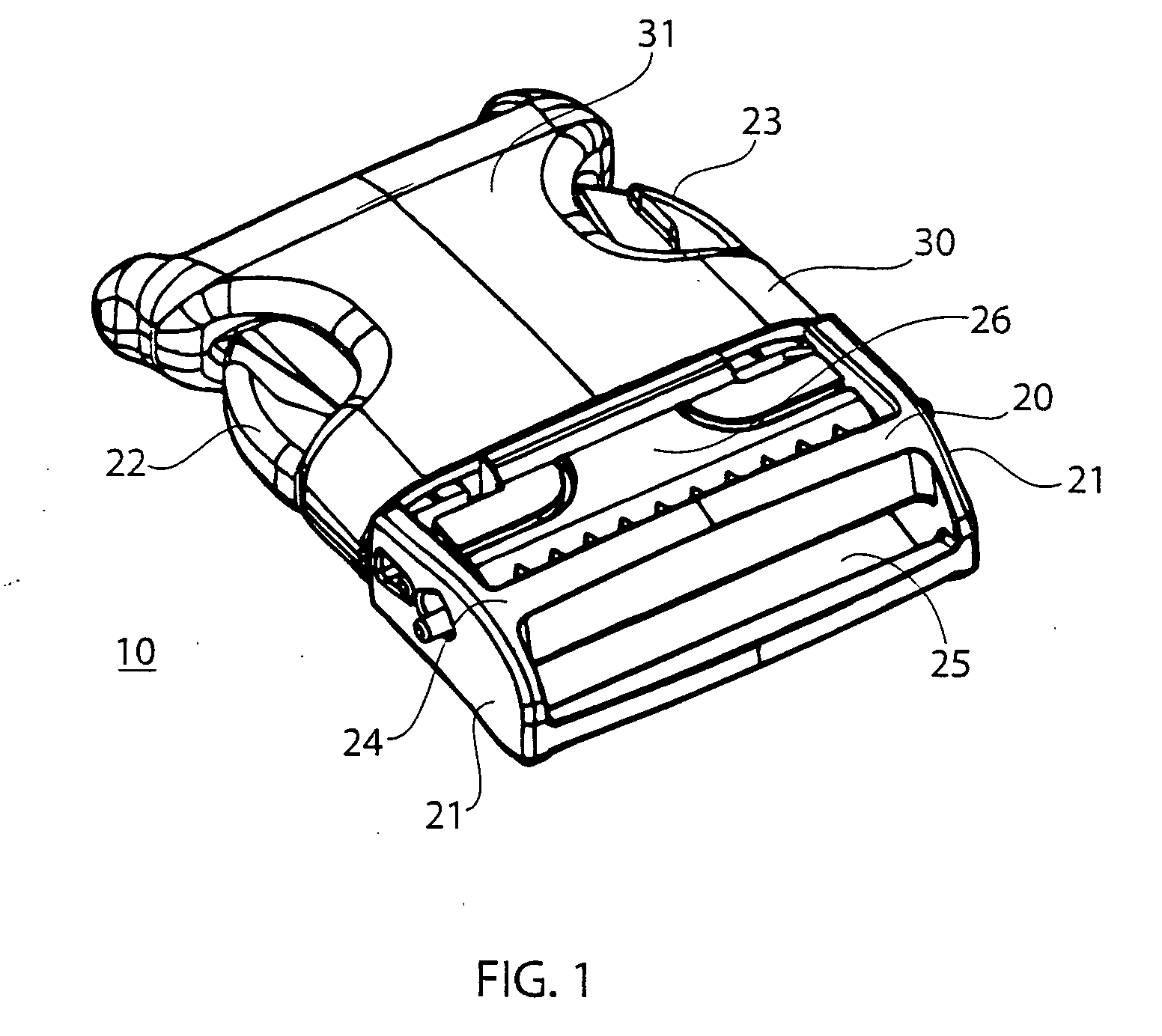

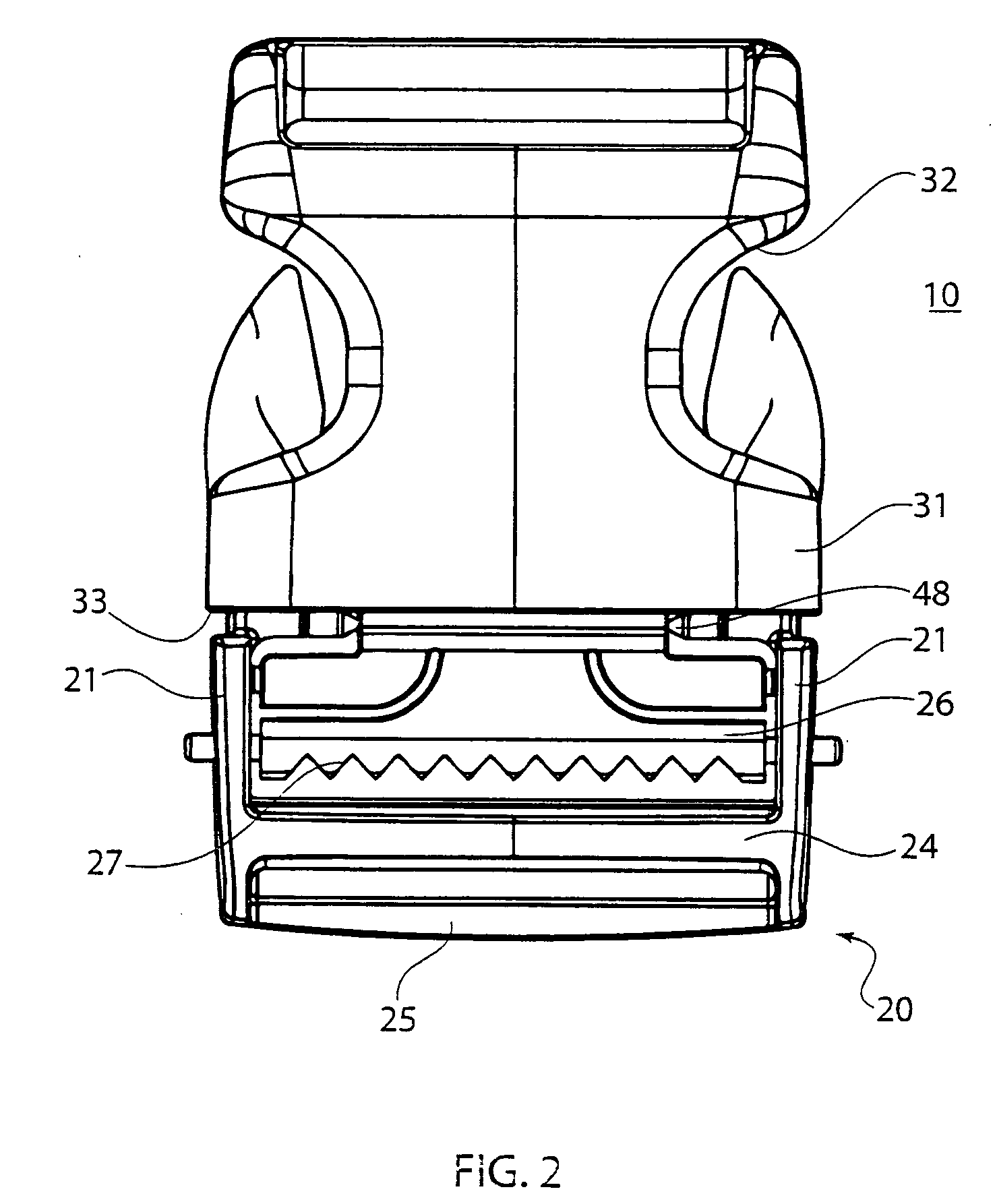

[0031] Referring now in detail to the drawings, FIGS. 1-3 show buckle 10 in a locked position. Buckle 10 comprises a male portion 20 and a female portion 30. Male portion 20 has two sidewalls 21, two locking arms 22, 23, a first strap retaining bar 24 and a second strap retaining bar 25. A slidable or pivotable strap gripping bar 26 is disposed adjacent first strap retaining bar 24.

[0032] Strap gripping bar 26 has a plurality of teeth 27 disposed along a face adjacent strap retaining bar 24. Strap gripping bar 26 is connected to male portion 20 via two protrusions 28, 29 on each end of strap gripping bar 26, which extend through two apertures 40,41 on each of sidewalls 21 of male portion 20. The shape of the protrusions 28, 29 and of apertures 40, 41 are such that strap gripping bar 26 can slide and / or pivot between a gripping position and a release position, which will be described in detail below. A detailed picture of male portion 20 is shown in FIG. 4, and a detailed picture of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com