Intensifier

a technology of inverter and airflow rate, which is applied in the field of inverter, can solve the problems of insufficient air flow rate, damage to one or more components in the rack, and failure of one or more rack components, etc., and achieves the effect of discharging waste heat, reducing heat loss, and increasing air flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following detailed description and in the several figures of the drawings, like elements are identified with like reference numerals.

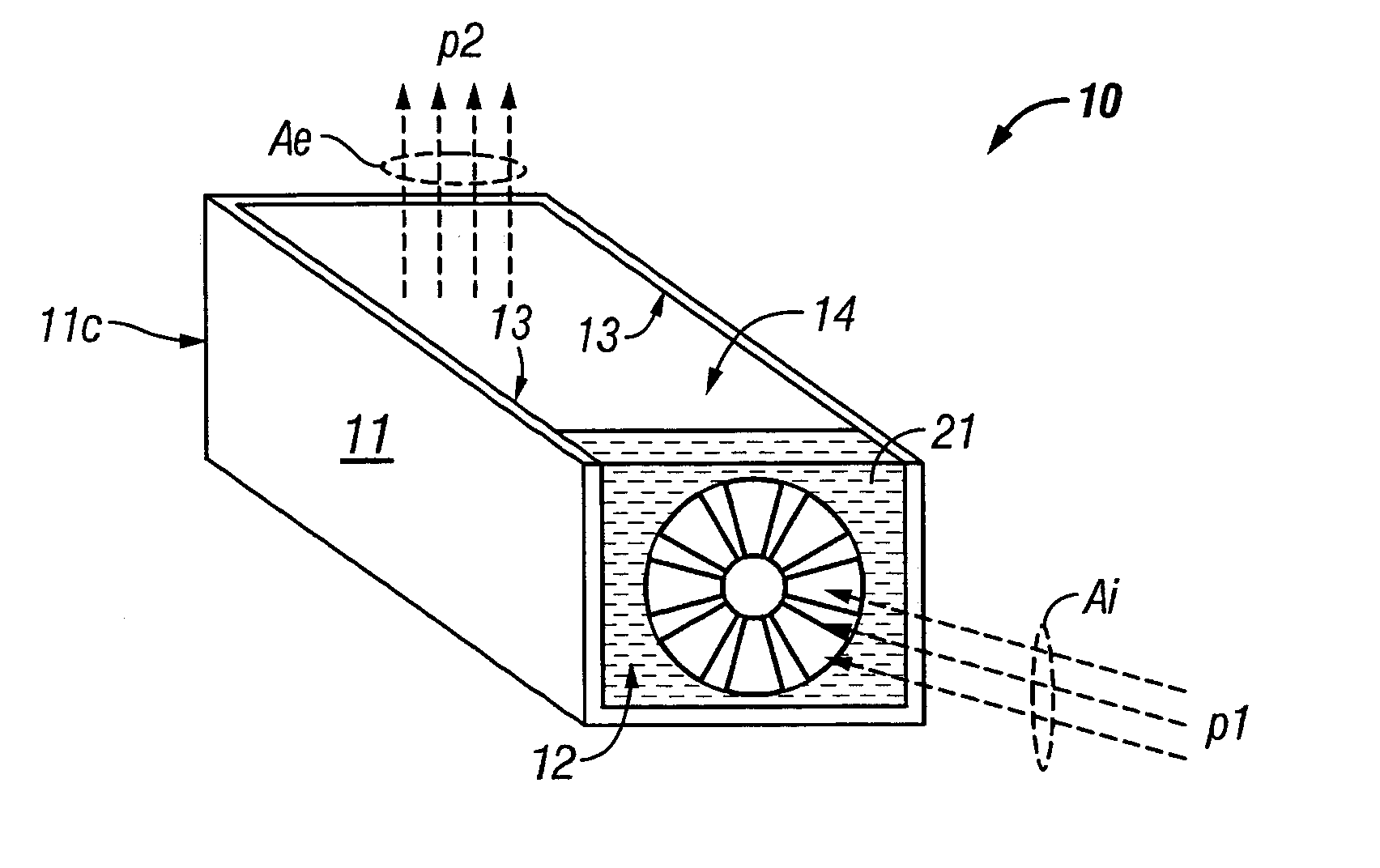

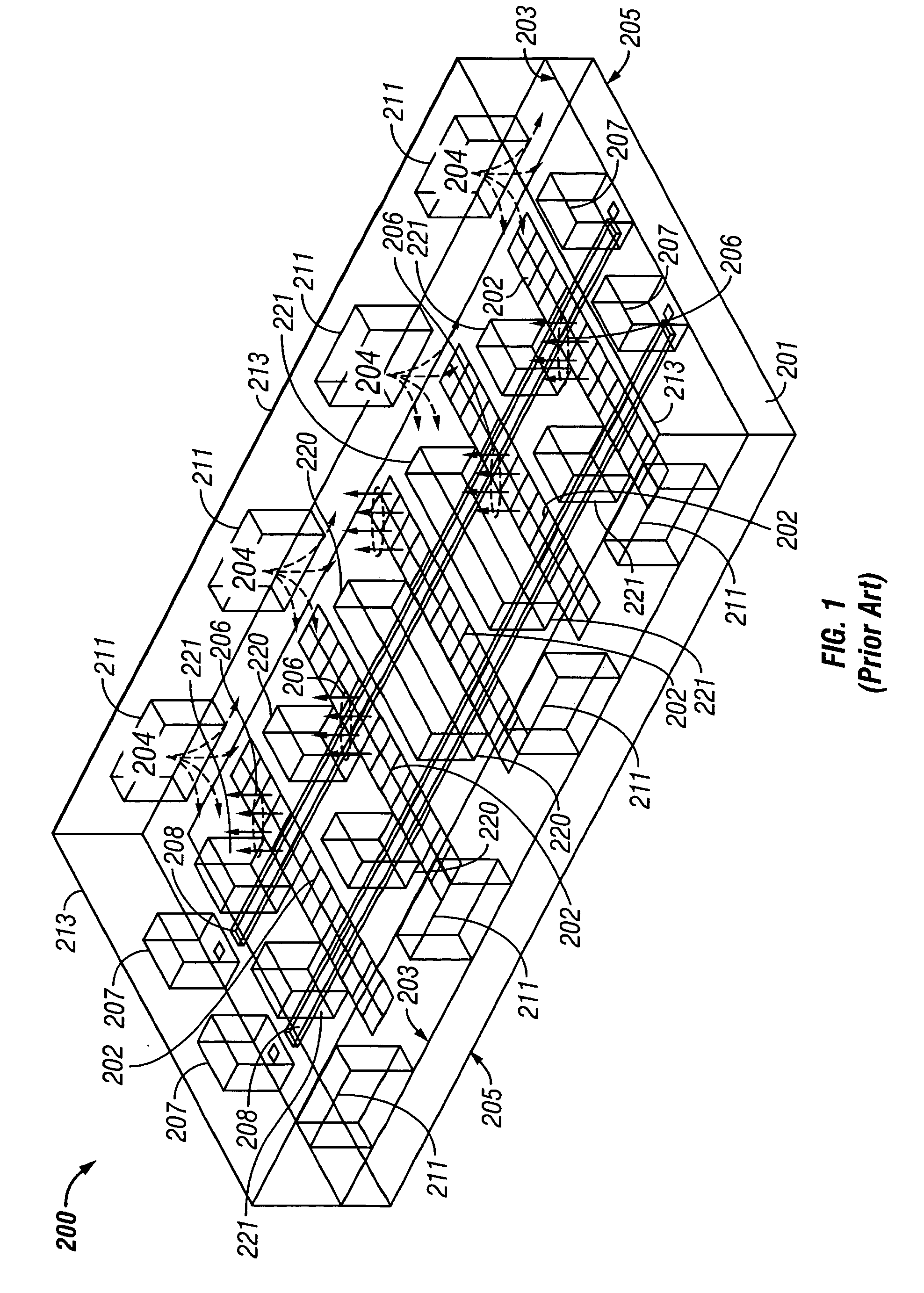

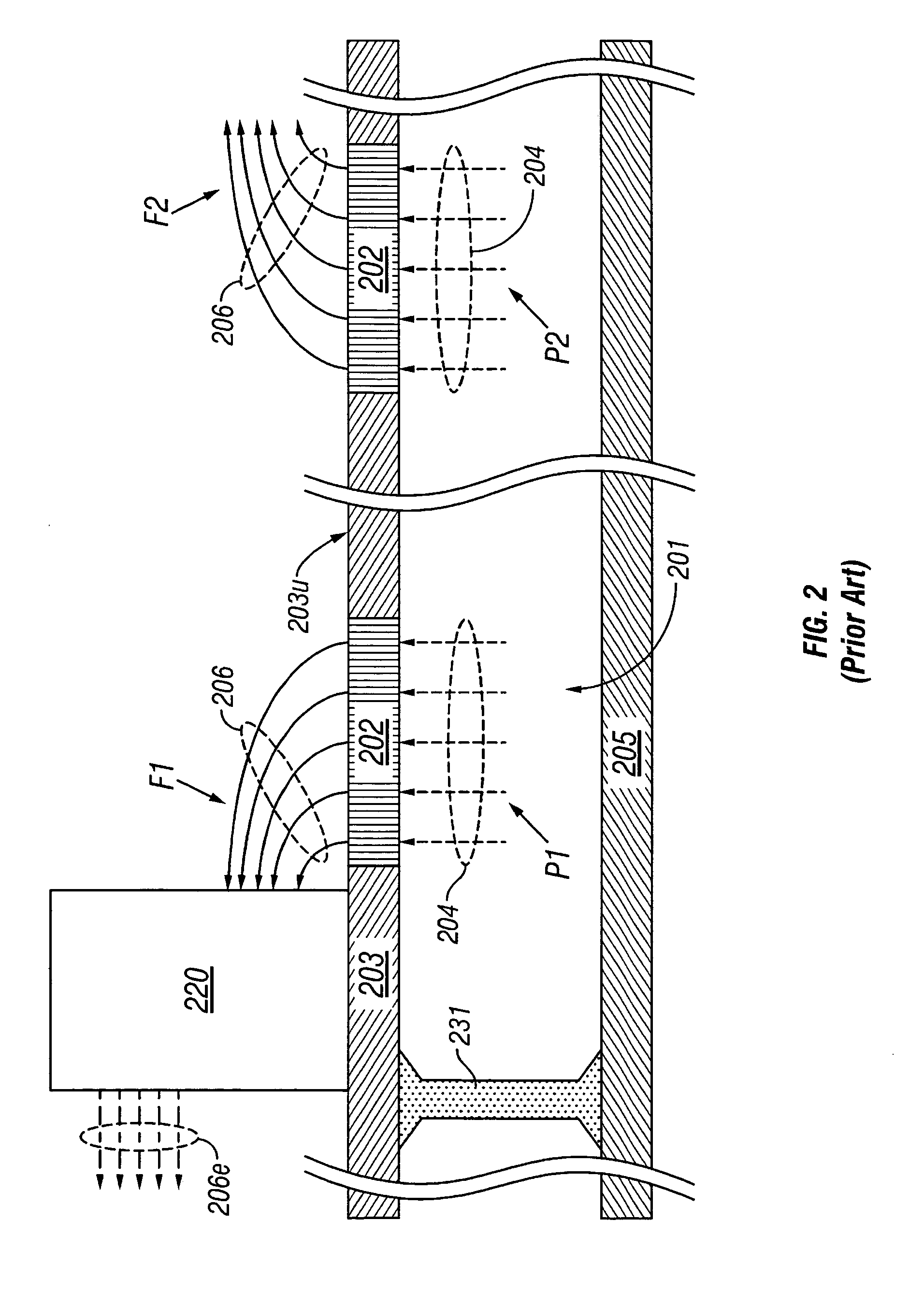

[0039] As shown in the drawings for purpose of illustration, the present invention is embodied in an intensifier comprising an enclosure that includes an intake port, an exhaust port, an interior surface that defines a chamber, and an air flow source in communication with the chamber. The enclosure can be positioned in a space that includes an ambient at a first pressure and the exhaust port can be positioned adjacent to an opening in a surface that partially encloses the space. The air flow source draws the ambient into the chamber through the intake port and expels the ambient out of the chamber through the exhaust port at a second pressure that is higher than the first pressure.

[0040] Turning to FIGS. 3a and 3b, an intensifier 10 includes an enclosure 11 that includes an intake port 12, an exhaust port 14, and an interior surface 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com