Metal heater

a heater and metal technology, applied in the field of metal heaters, can solve the problems of difficult temperature control, dispersion of temperature or damage in the semiconductor wafer, and metal heaters with such structures, and achieve the effects of shortening the recovery time, quick heating of objects, and constant distance between the heating face of the metal plate and the semiconductor wafer or the lik

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

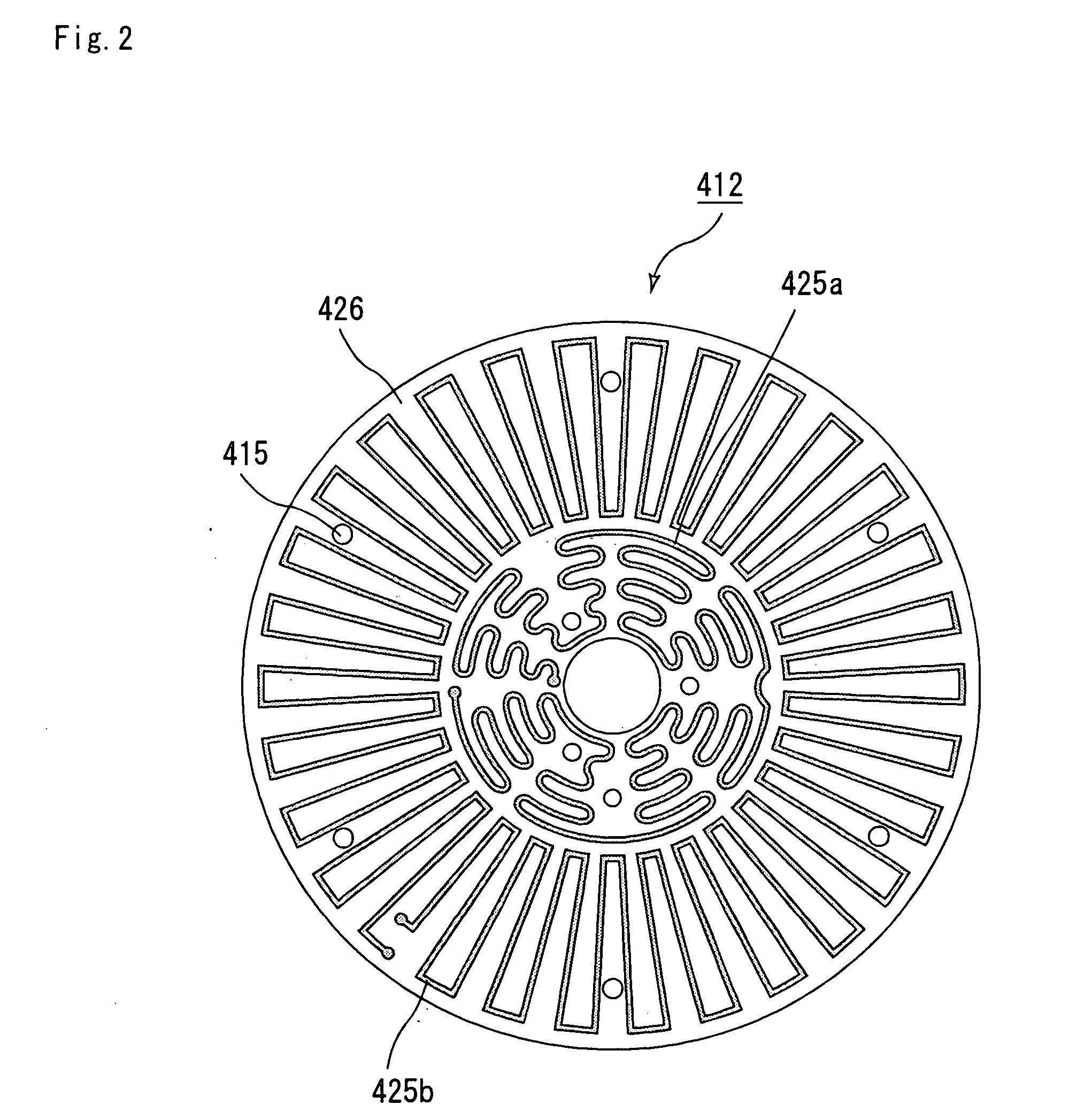

[0310] Manufacturing of metal heater (see FIGS. 1 and 2)

[0311] (1) A plate-shaped member, made of an aluminum-copper alloy (A2219 (JIS-H4000)), was machined at outer-diameter portion by using an NC lathe (manufactured by Washino Machinery Co., Ltd.) and formed into a disk shape, and this plate-shaped member was then subjected to an end-face machining process, a surface machining process and a rear-face machining process so that a disk-shaped member for an upper metal plate and a disk-shaped member for a lower metal plate were manufactured.

[0312] Next, each of parts to be through holes 415 to which lifter pins used for supporting a semiconductor wafer 419 are inserted, each of concave portions in which supporting pins 418 are placed and each of parts to be a bottomed hole 414 in which a temperature measuring element 416 is embedded were formed by using a machining center (Hitachi Seiki Co., Ltd.).

[0313] Here, the through holes 415 were formed at three positions, and the concave po...

example 2

Manufacturing of Metal Heater

[0330] The same processes as those of Example 1 were carried out except that the thickness of the upper metal plate 411 was set to 20 mm and that the thickness of the lower metal plate 421 was set to 5 mm so that a metal heater was manufactured.

example 3

Manufacturing of Metal Heater

[0331] The same processes as those of Example 1 were carried out except that the thickness of the upper metal plate 411 was set to 25 mm and that the thickness of the lower metal plate 421 was set to 10 mm so that a metal heater was manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com