Bone implant, in particular, an inter-vertebral implant

a technology of bone implants and implants, which is applied in the field of bone implants, can solve the problems of easy leakage of filling and inability to allow optimal bone tissue growth, and achieve the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

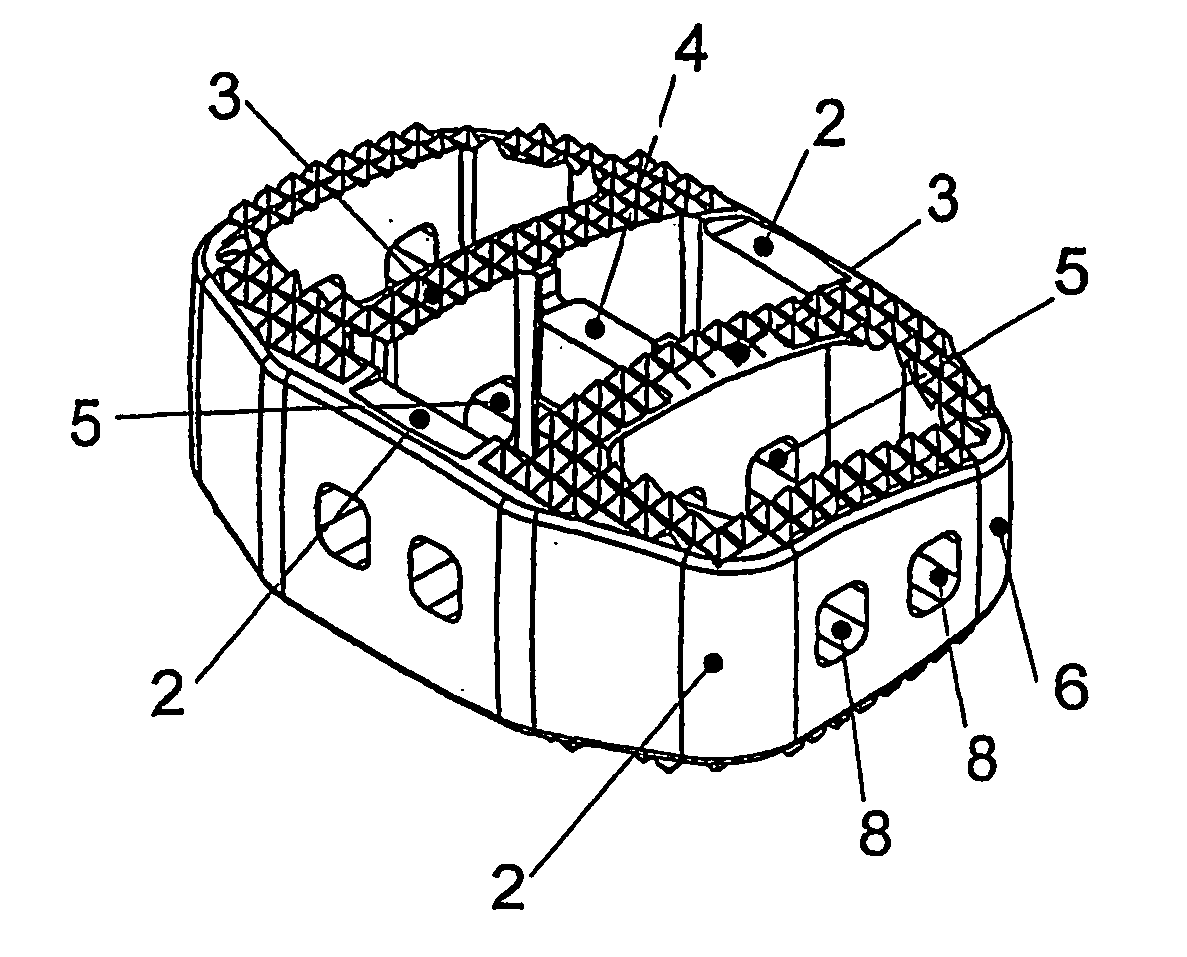

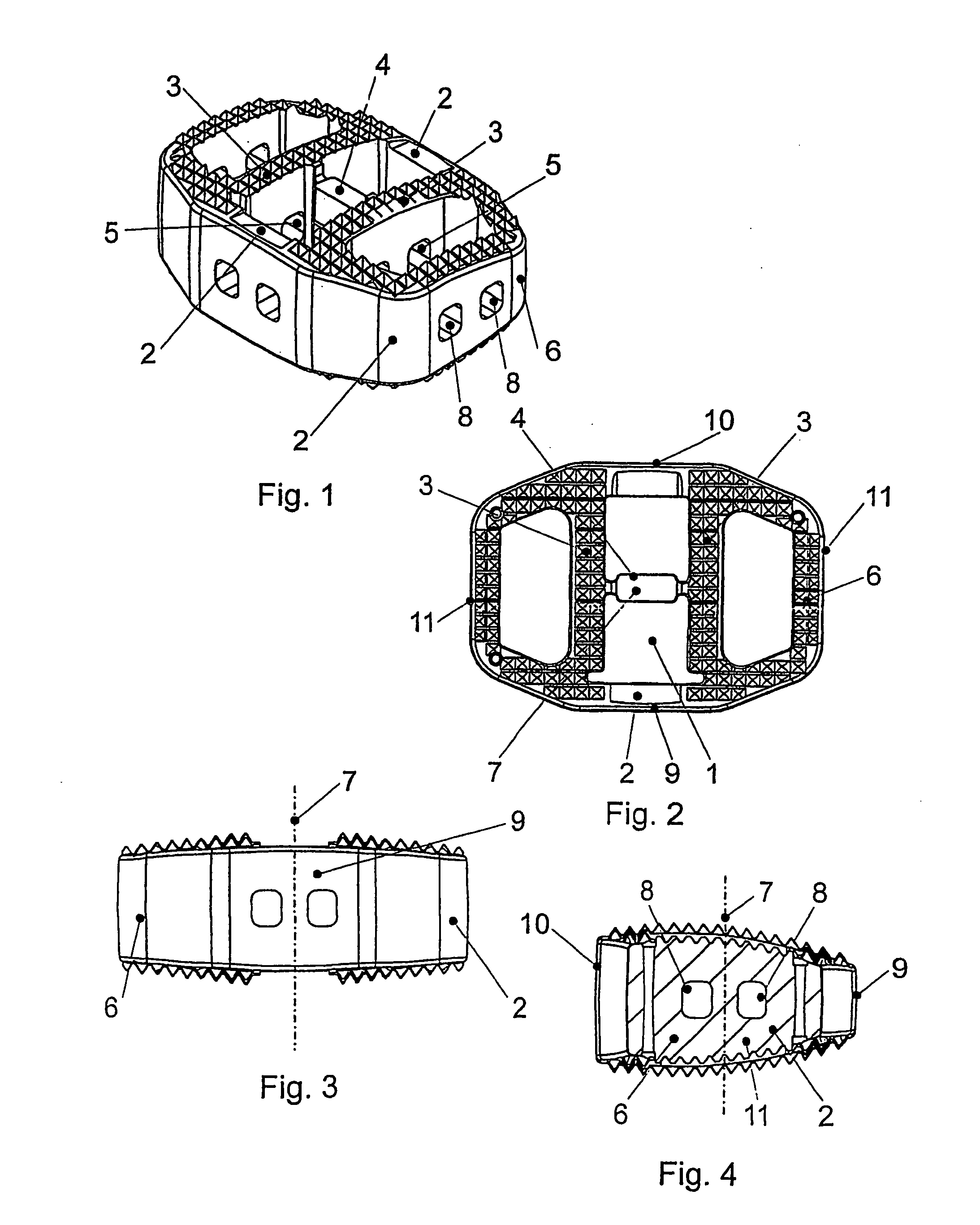

[0017] Referring to FIGS. 1 through 4, there is shown an inter-vertebral implant configured for insertion between the adjacent vertebral endplates and permitting growth of an osseous structure through the implant. The inter-vertebral implant may be a generally annular or circular shaped hollow body 1 comprising a mantle or sleeve 6 defining a hollow cylindrical or cone section which has a front section 9, a rear section 10, and two lateral sections 11, and further defines a cylindrical or central axis 7. The hollow body 1 may be divided into chambers by at least two intermediate walls 3 running essentially or substantially parallel to cylindrical axis 7. The intermediate walls or partitions 3 connect front section 9 with back or rear section 10 of the sleeve 6, and may be supported, interconnected and spaced with respect to one another by at least one cross brace or strut 4. Intermediate walls 3 increase the support areas on the neighboring vertebral body endplates, thereby reducing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com