Shoe with shell portions

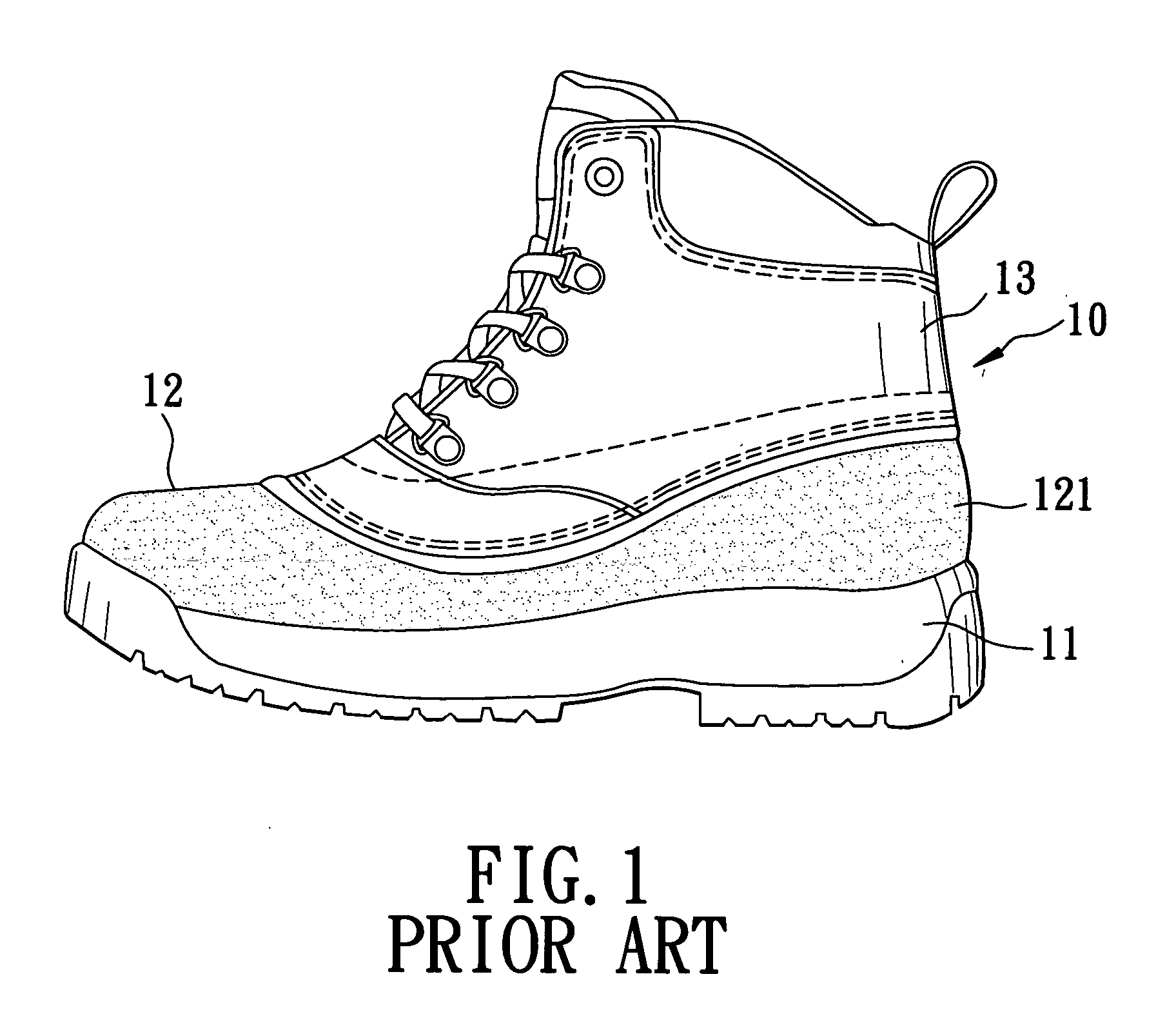

a shell and shoe technology, applied in the field of shoes, can solve the problems of increased molding cost and inability to adjust the size of the shoe, and achieve the effects of good bendability, cost effectiveness, and light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Referring to FIGS. 3 and 4, the first preferred embodiment of a shoe 30 according to the present invention is shown to include a first shell portion 31, a second shell portion 32, and an outsole unit 33. The outsole unit 33 includes a midsole 331 and an outsole 332 connected to a bottom surface of the midsole 331.

[0024] The second shell portion 32 is more flexible than the first shell portion and is composed of a plurality of pieces. In this embodiment, the second shell portion 32 includes a front part 321 and an instep part 322. The second shell portion 32 complements the first shell portion 31 to form an upper, and is mechanically connected to the first shell portion 31.

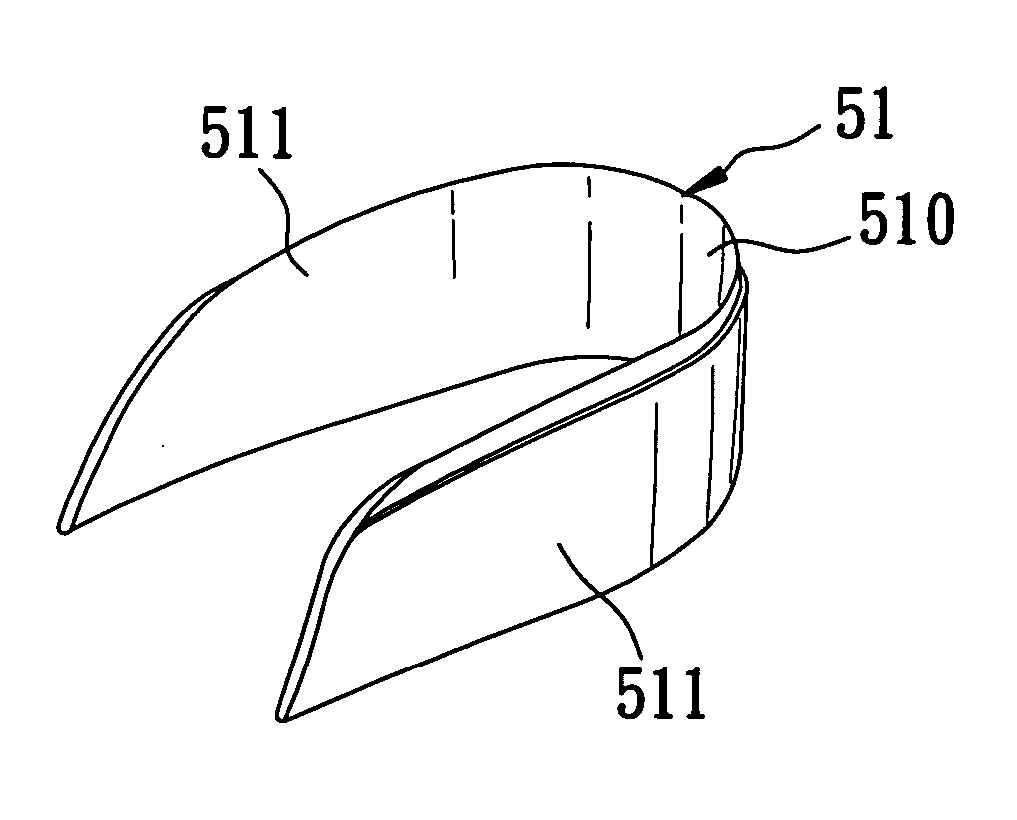

[0025] As shown in FIG. 4, the first shell portion 31 includes a sole part 312 which is secured to the midsole 331 and which has at least a heel region 3121, and a surrounding wall 310 which projects upward from a periphery of the heel region 3121 and which has a substantially U-shaped cross-section that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com