Solar magnetohydrodynamic power generation

a magnetohydrodynamic and solar energy technology, applied in the field of solar magnetohydrodynamic power generation, can solve the problems of nuclear power plants having the added risk of potential accidents with disastrous consequences for both human life and the environment, and the use of fossil fuels has a detrimental effect on the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

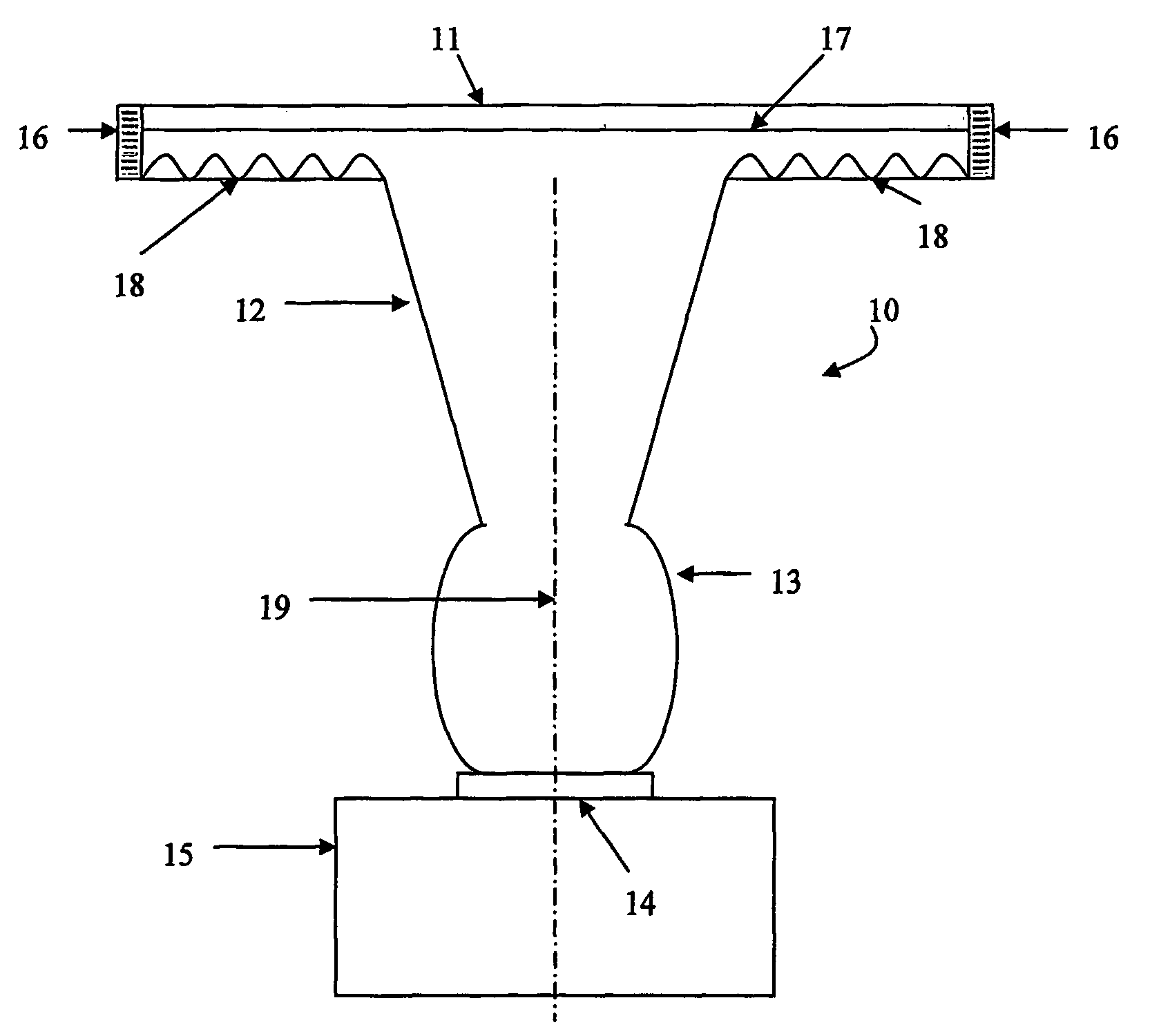

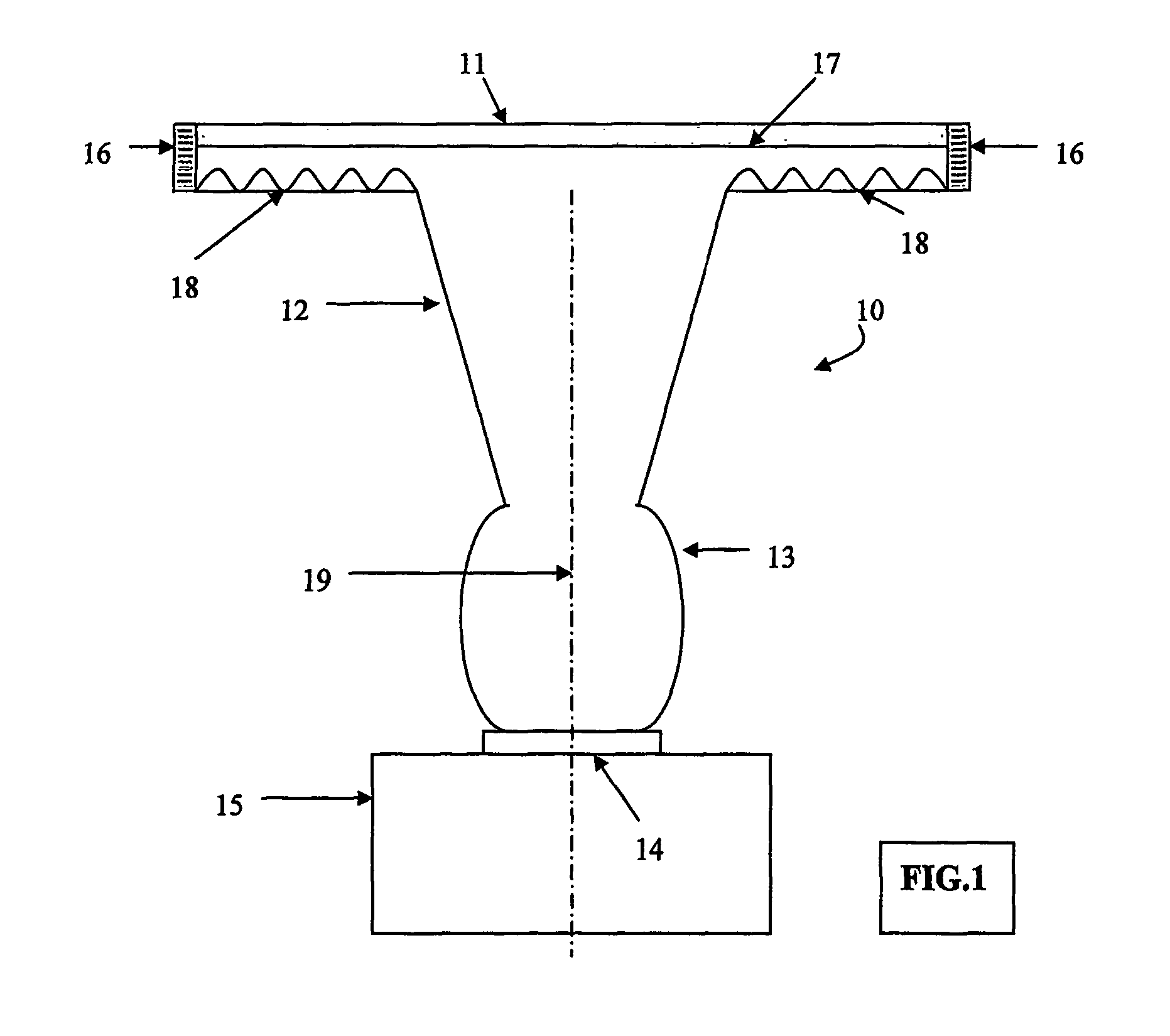

[0060] Referring to a first embodiment illustrated in FIG. 1, a multi-stage solar collector 10 comprises a planar collector 11, a paraboloidal mirror 12 and a non imaging compound parabolic concentrator 13. Thus a combination of lens and mirror systems is utilised in the multi-stage collector 10, which is coupled to a solar oven 15 in the embodiment. Although the lens comprised by the planar collector 11 and transparent window 14 into the solar oven 15 may be composed of quartz, glass and plastic are both cheaper. Glass is opaque for selected spectral regions in the infrared and only for ultraviolet wavelengths of less than 0.38 microns.

[0061] In order to provide efficient light transmission in desired wavelengths with low reflection, tailored plastics such as vinyl and polyethylene can be utilised. When exposed to sunlight and various weathering elements, and while glass is heavy and plastic is light, both have proven to be durable. A low-index (less reflection) of refraction mater...

third embodiment

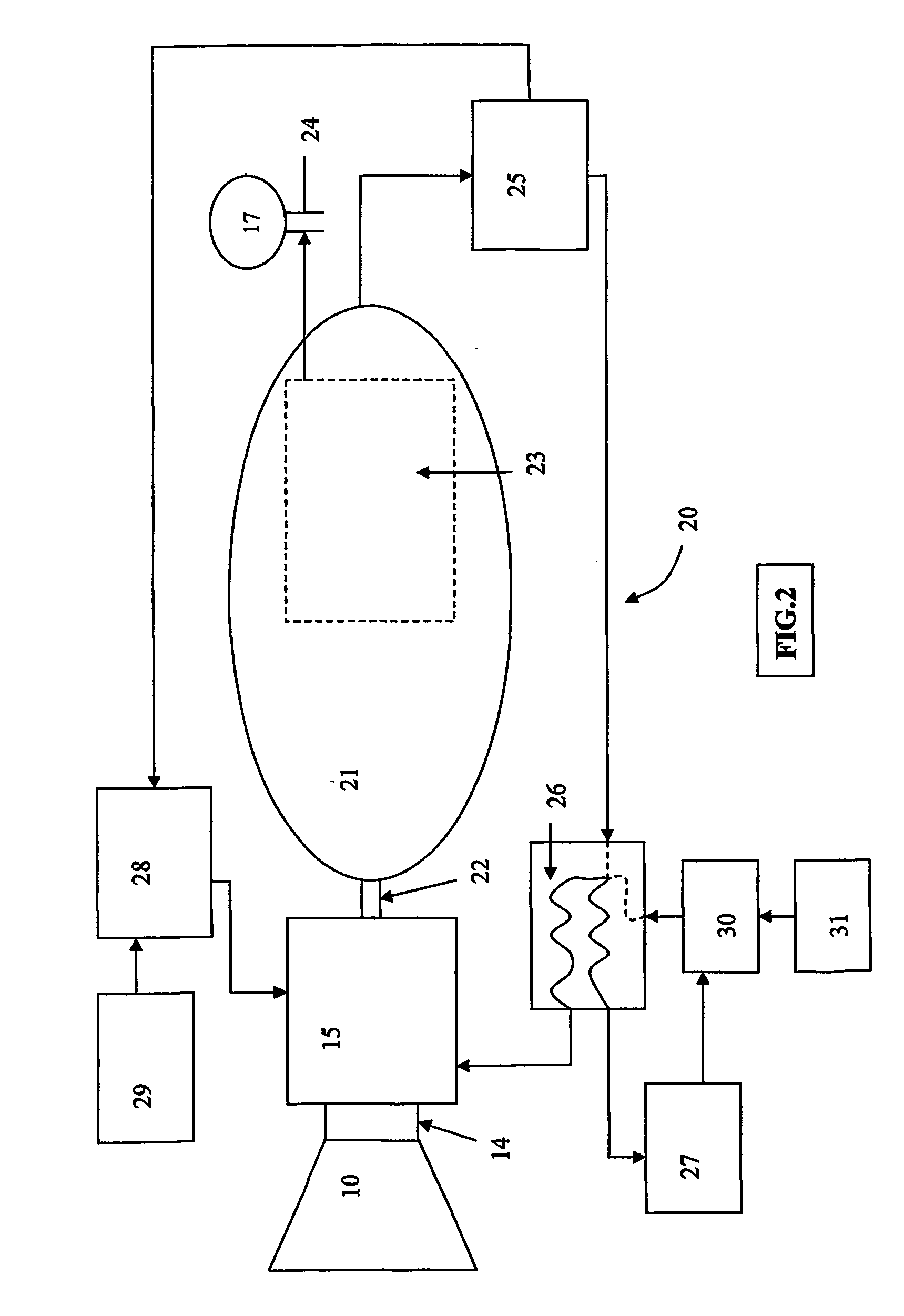

[0095] In the invention, a voltage source (not shown) is attached to the solar oven 15. By way of example the voltage source could be one or a plurality of a photovoltaic cell(s) and / or a battery. In one form of the embodiment, carbon particles are seeded into the solar oven 15. In this invention the high voltage source may also be used in combination with the radiation energy source using a compound collector 10. The carbon particles preferably have a mean diameter of between about 0.02×10−6 m to 0.04×10−6 m and are of sufficient number to provide for a charge density per cubic meter of about 2×1018 within the MHD generator 20 when the particles are electrostatically charged. Carbon particles are inserted into the gas flow from an external source 29 with a carbon particle injector of known construction. The microscopic carbon particles can be externally produced by techniques used in the manufacture of carbon black for the rubber industry, for example. A positive or negative high v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com