Press molding apparatus and method of producing a glass optical element using the apparatus

a technology of glass optical elements and press molding, which is applied in the direction of glass making apparatus, glass shaping apparatus, instruments, etc., can solve the problems of insignificant thermal uniformity, difficult to uniformly heat the molding surfaces in the single-line arrangement, and disadvantageous single-line arrangement of molding surfaces, so as to increase the temperature elevation rate of pressing molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

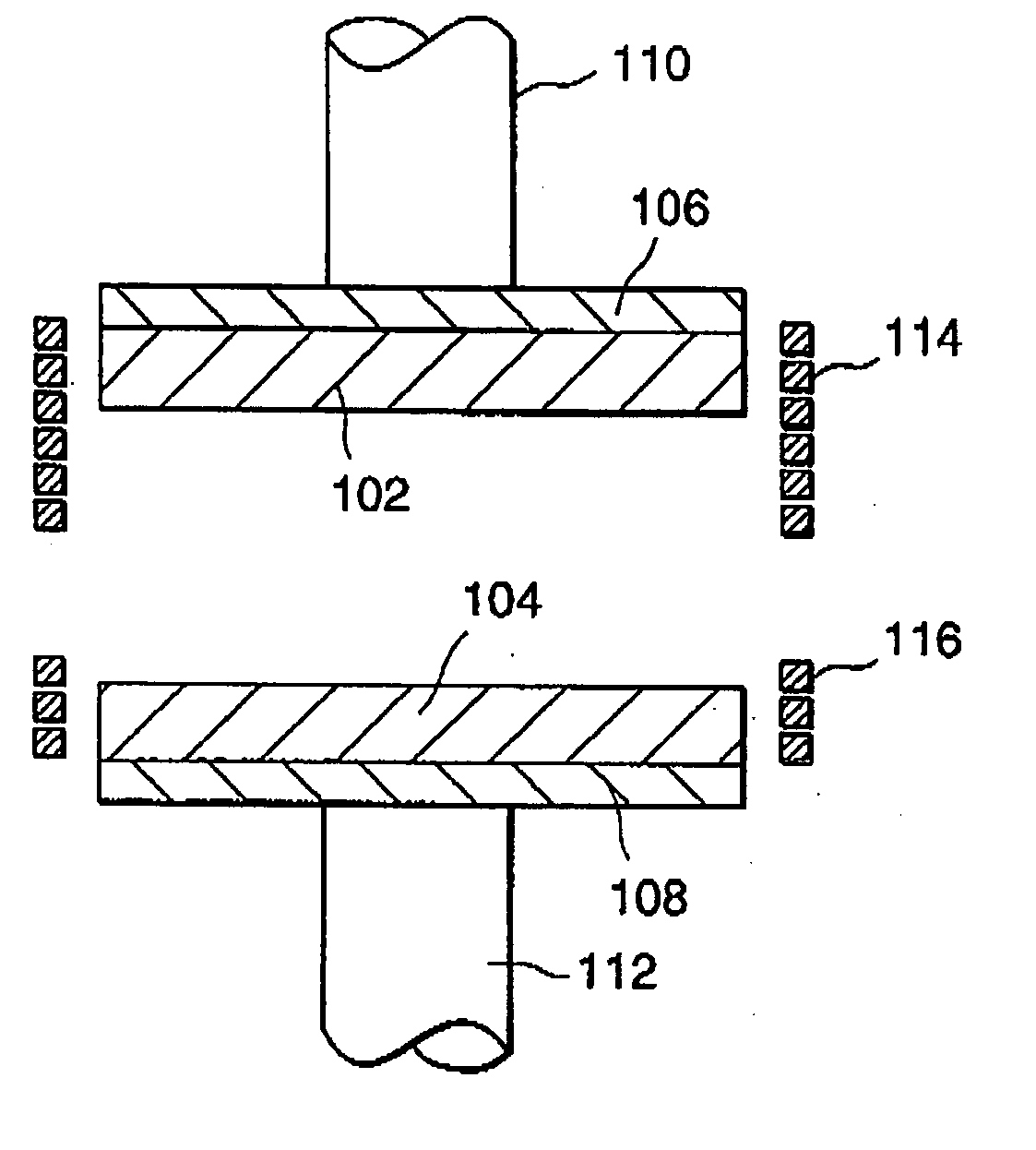

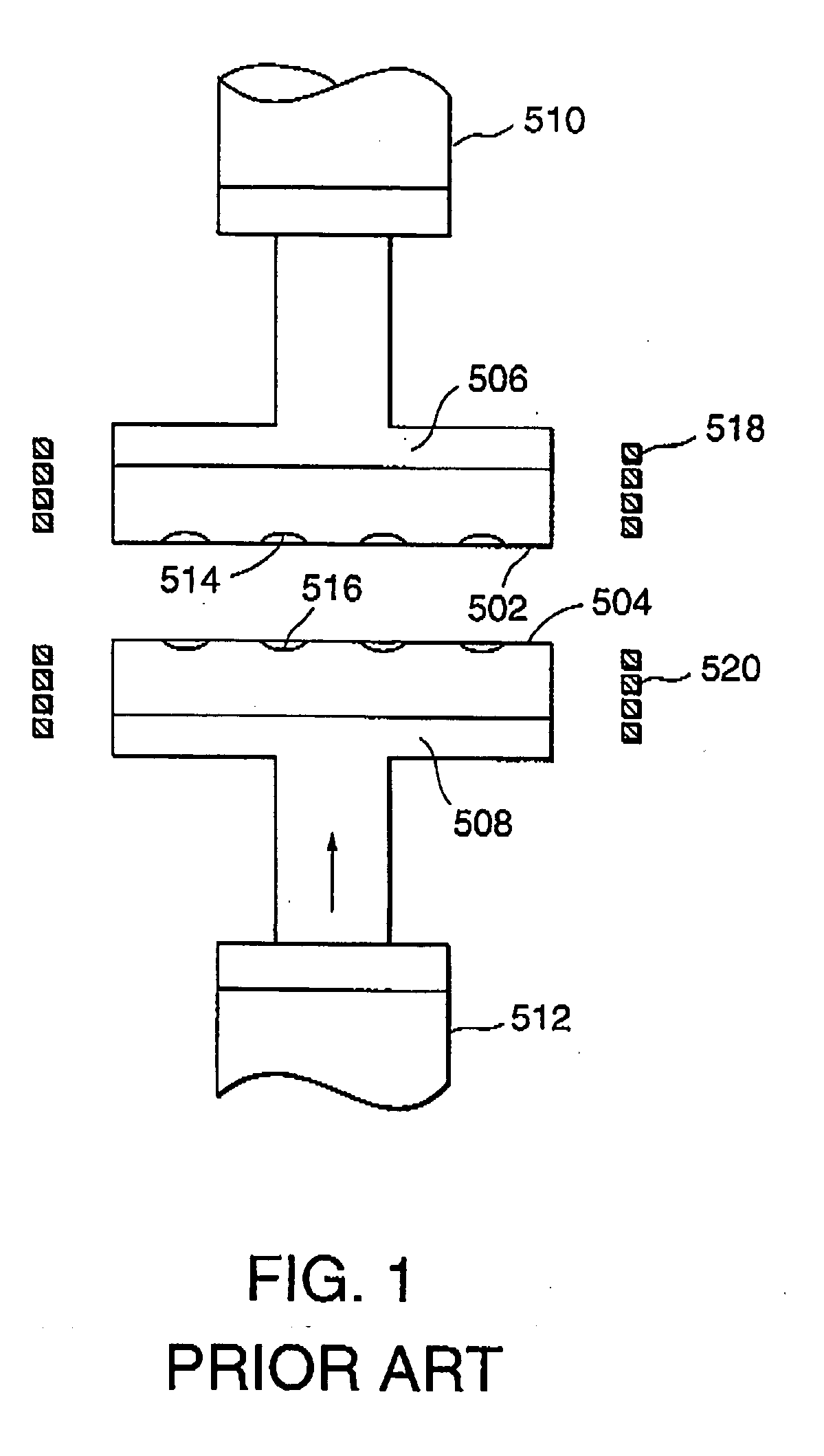

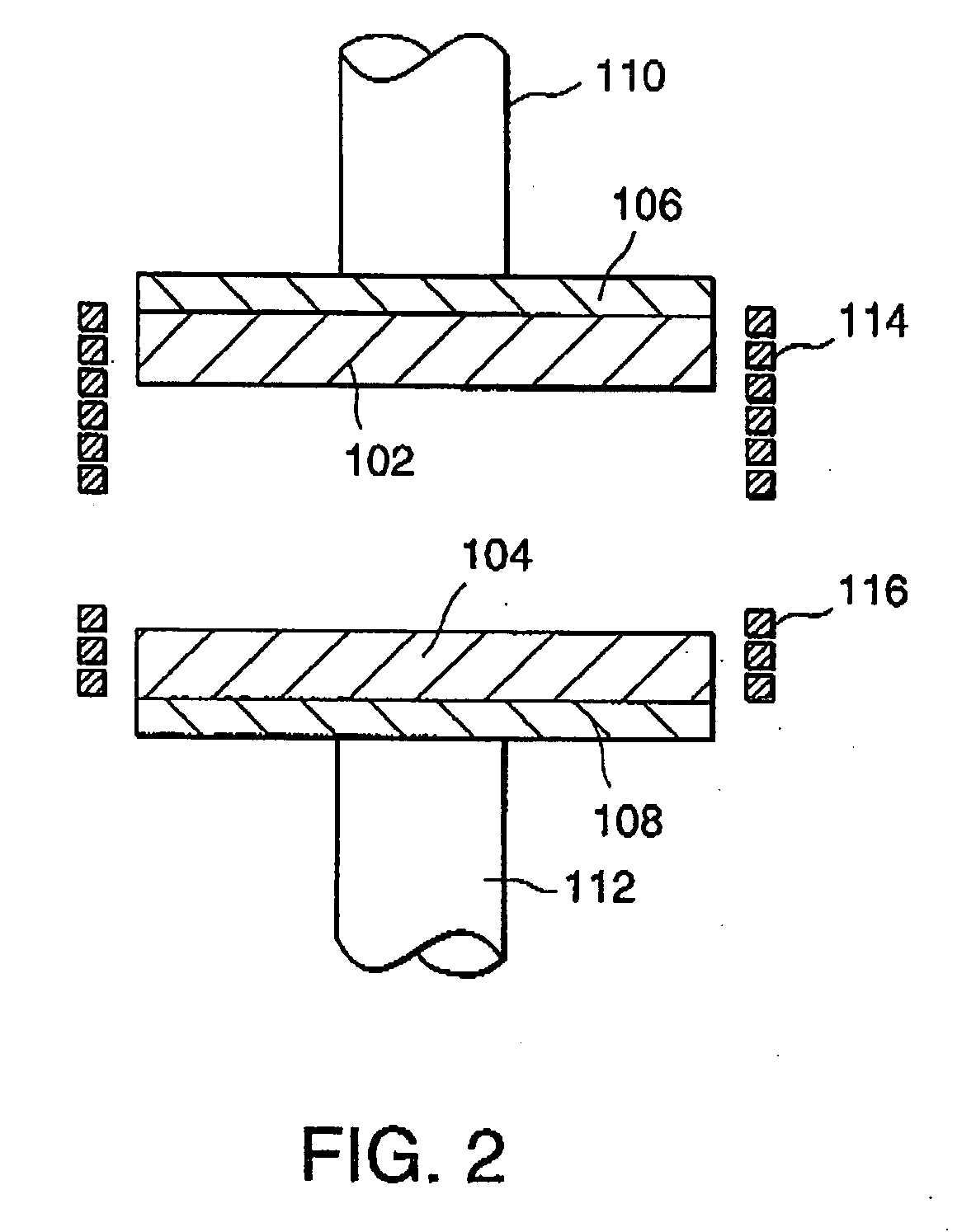

[0043] At first referring to FIG. 2, a press molding apparatus according to this invention will be described. For example, the press molding apparatus is used to produce a medium-aperture lens having a diameter of 17 mm by the use of a preform having a flat spherical shape. The press molding apparatus has a pressing mold comprising an upper mold 102 and a lower mold 104 for clamping and pressing the preform. Each of the upper and the lower molds 102 and 104 has an elongated shape extending in a transversal or horizontal direction in the figure and is made of, for example, a tungsten alloy. The upper and the lower molds 102 and 104 have a plurality of molding portions (which will later be described) formed on confronting surfaces thereof, respectively, to provide preforms with a predetermined shape. The upper and the lower molds 102 and 104 are attached through supporting members 106 and 108 to upper and lower main shafts 110 and 112, respectively, on the sides opposite to the confro...

second embodiment

[0056] Referring to FIG. 7, a press molding apparatus comprises a mother mold 600 having an elongated shape and six pairs of upper and lower mold members 602 and 604 supported by the mother mold 600 to be vertically movable. Each of the upper and the lower mold members 602 and 604 is made of cemented carbide and has a molding surface (i.e., a surface for pressing a preform P) coated with a thin film of a precious metal alloy. The mother mold 600 is made of a tungsten alloy and has a thermal expansion coefficient slightly greater than that of cemented carbide. The mother mold 600, the upper mold members 602, and the lower mold members 604 are supported on a tray 606 and transferred into a forming chamber (not shown). Between each of the lower mold members 604 and the tray 606, a spacer 608 is inserted to adjust the thickness of each lens. The tray 606 is mounted on a lower main shaft 612 driven in the vertical direction by a motor mechanism (not shown). By moving the lower main shaf...

fourth embodiment

[0066] As a specific example for the fourth embodiment, press molding was performed by the use of the press molding apparatus in which the perforations were formed throughout an entire periphery of the mother mold and particularly densely formed in the local regions corresponding to the areas between every adjacent ones of the molding surfaces (see FIG. 5). As a result, it was possible to shorten the time before the target temperature (Table 1) was reached.

[0067] Next referring to FIG. 12, description will be made of a fifth embodiment of this invention. For example, a press molding apparatus according to the fifth embodiment is used to produce a medium-aperture lens having a diameter of 17 mm by the use of a preform prepared by preliminarily forming a glass material into a flat spherical shape. As illustrated in FIG. 12, the press molding apparatus comprises a pressing mold set including an upper mold 102 and a lower mold 104. Each of the upper and the lower molds 102 and 104 has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com