Inspection device of a tape reel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0002] 1. Technical Field of the Invention

[0003] The present invention relates to an inspection device of a tape reel and an inspection method for the same, especially relates to an inspection device for inspecting a dimension accuracy of a flange in a tape reel in which a pair of disk-shaped flanges are fixed in a mutually facing manner on both ends of a cylindrical hub, and an inspection method for the same.

[0004] 2. Background of the Invention

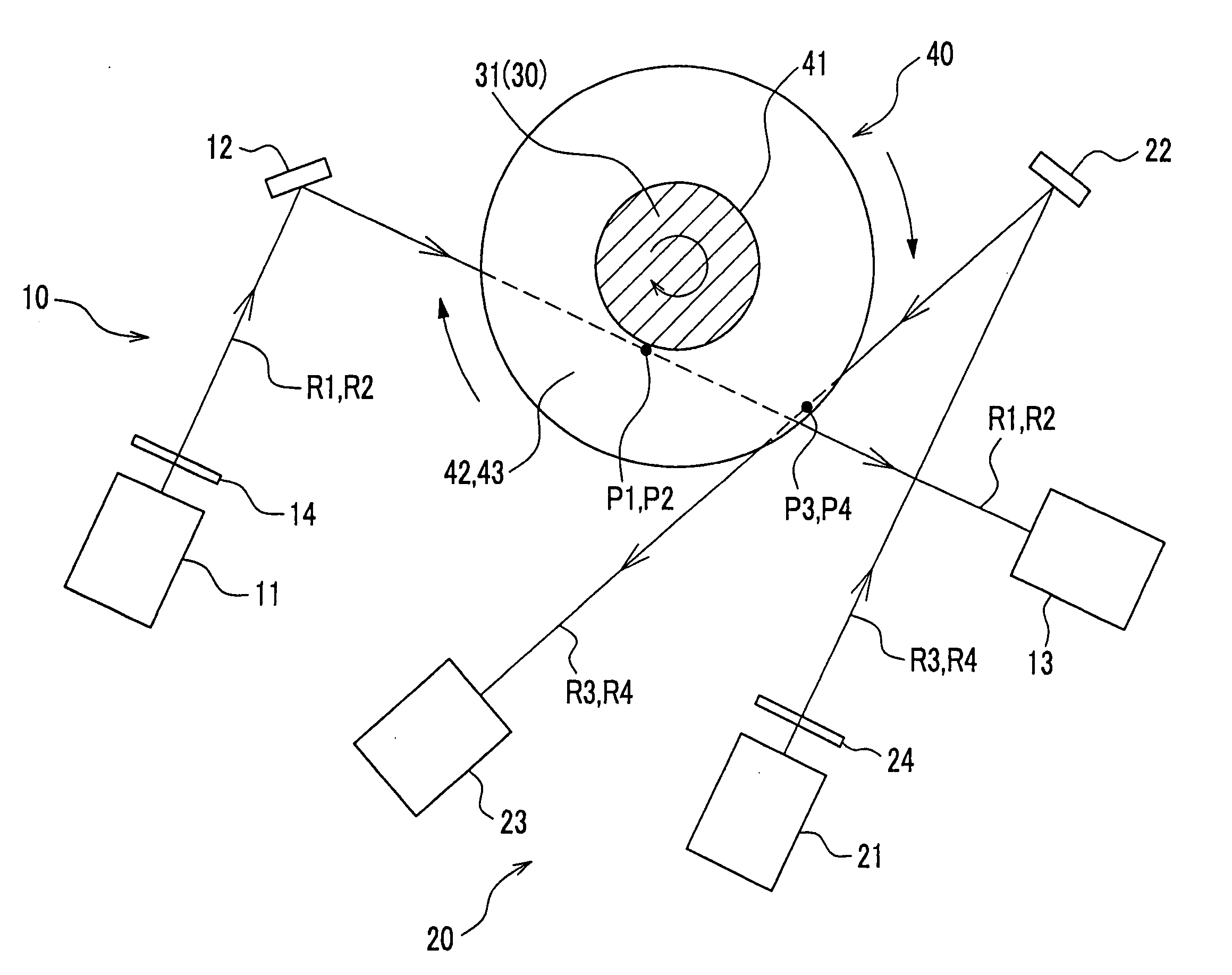

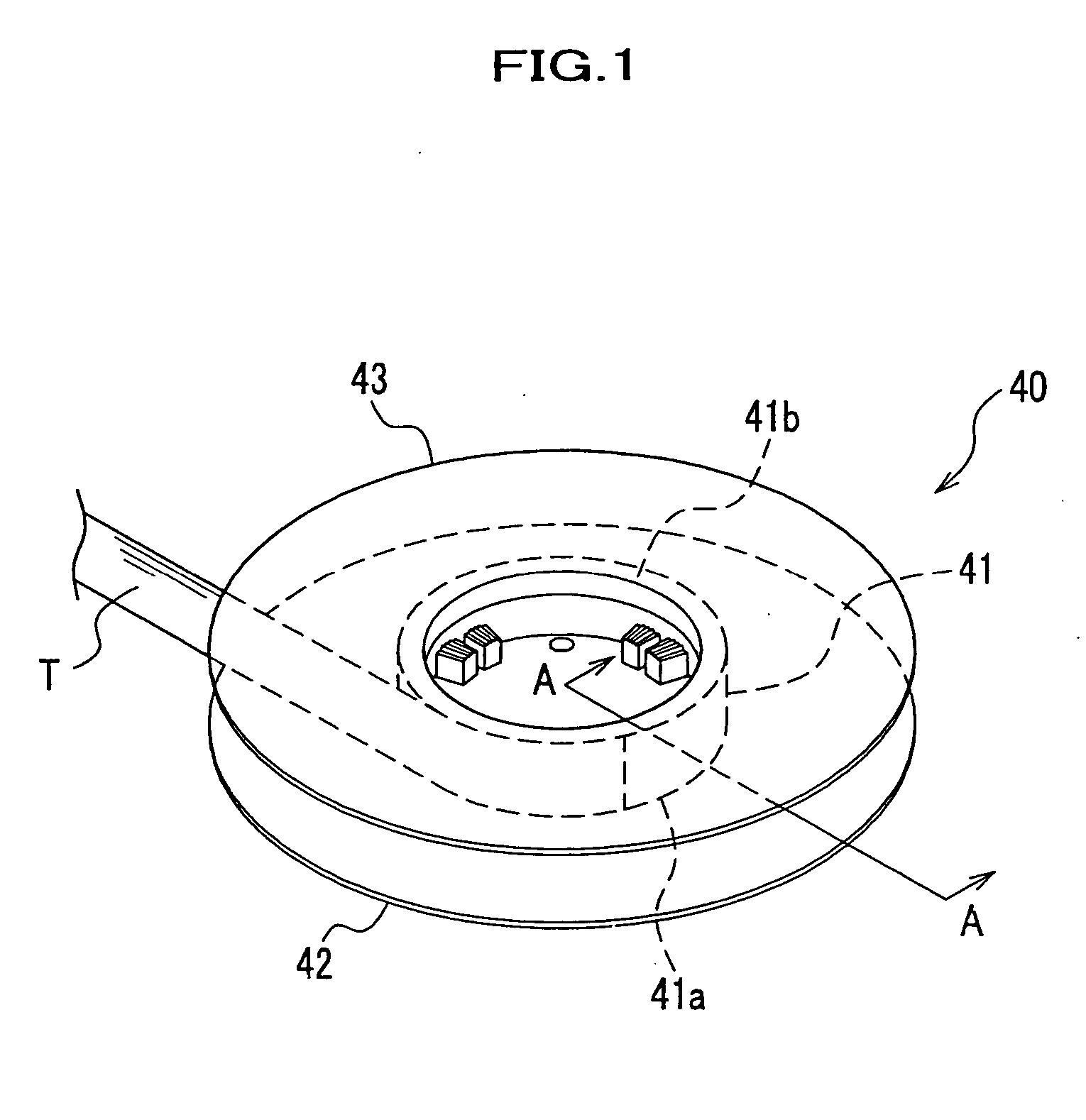

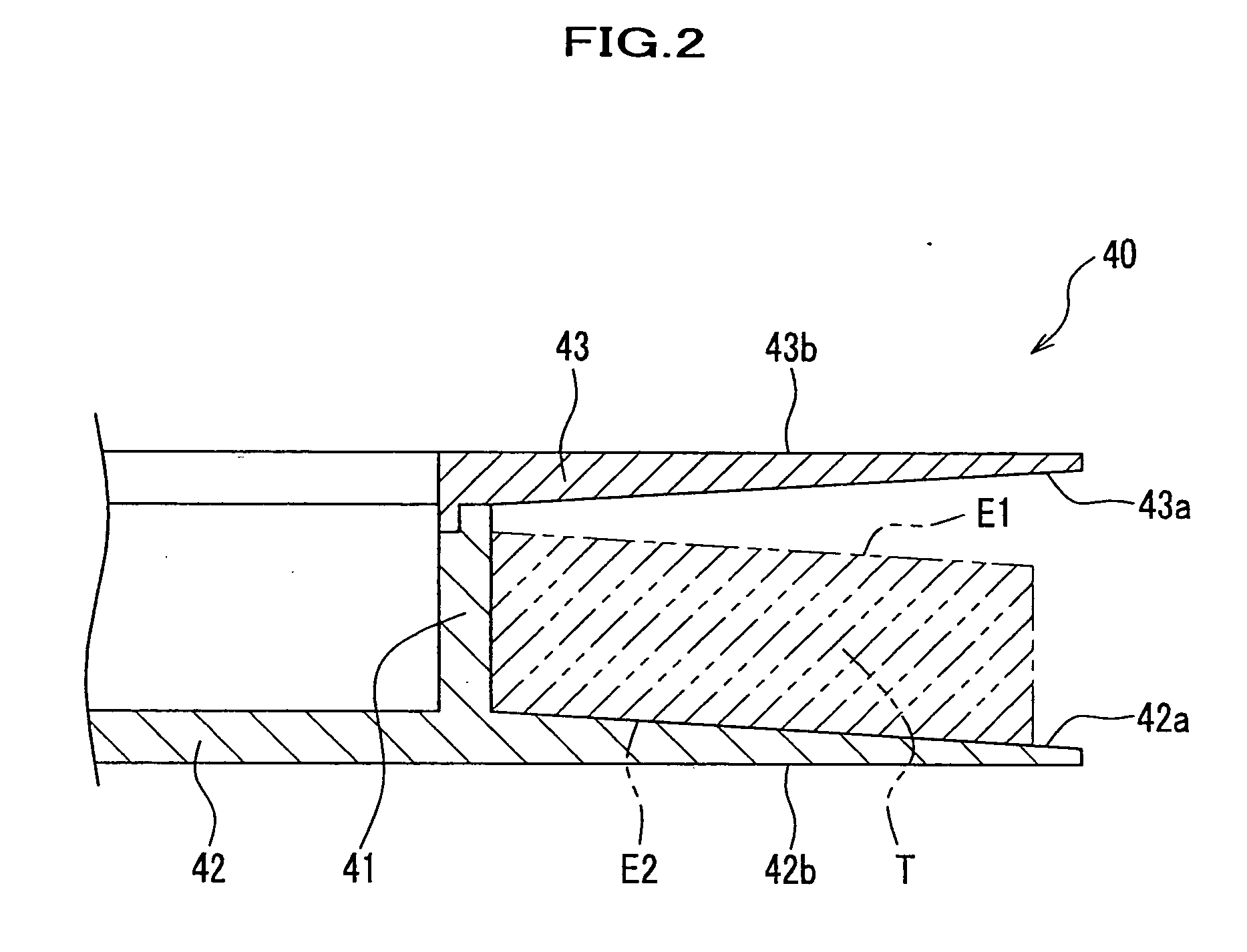

[0005] Conventionally, a magnetic tape serving as a magnetic recording medium is widely used as a recording medium used for other record reproducing devices such as an audio device and a video device. Generally various films, such as a magnetic tape, a movie film, and an X ray film, are wound on the tape reel as shown in FIG. 1 and 2 to be held. FIG. 1 is a perspective view showing one example of the tape reel. Also, FIG. 2 is a sectional view taken along the line A-A in FIG. 1.

[0006] As shown in FIG. 1, a tape reel 40 is constituted inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com