Apparatus and method for cleaning a surgically prepared bone surface

a surgical preparation and surface technology, applied in the field of surgical instruments, can solve the problems of difficult simultaneous manipulation and coordination of gas supply and suction, increased use of gas, and inability to secure joint replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

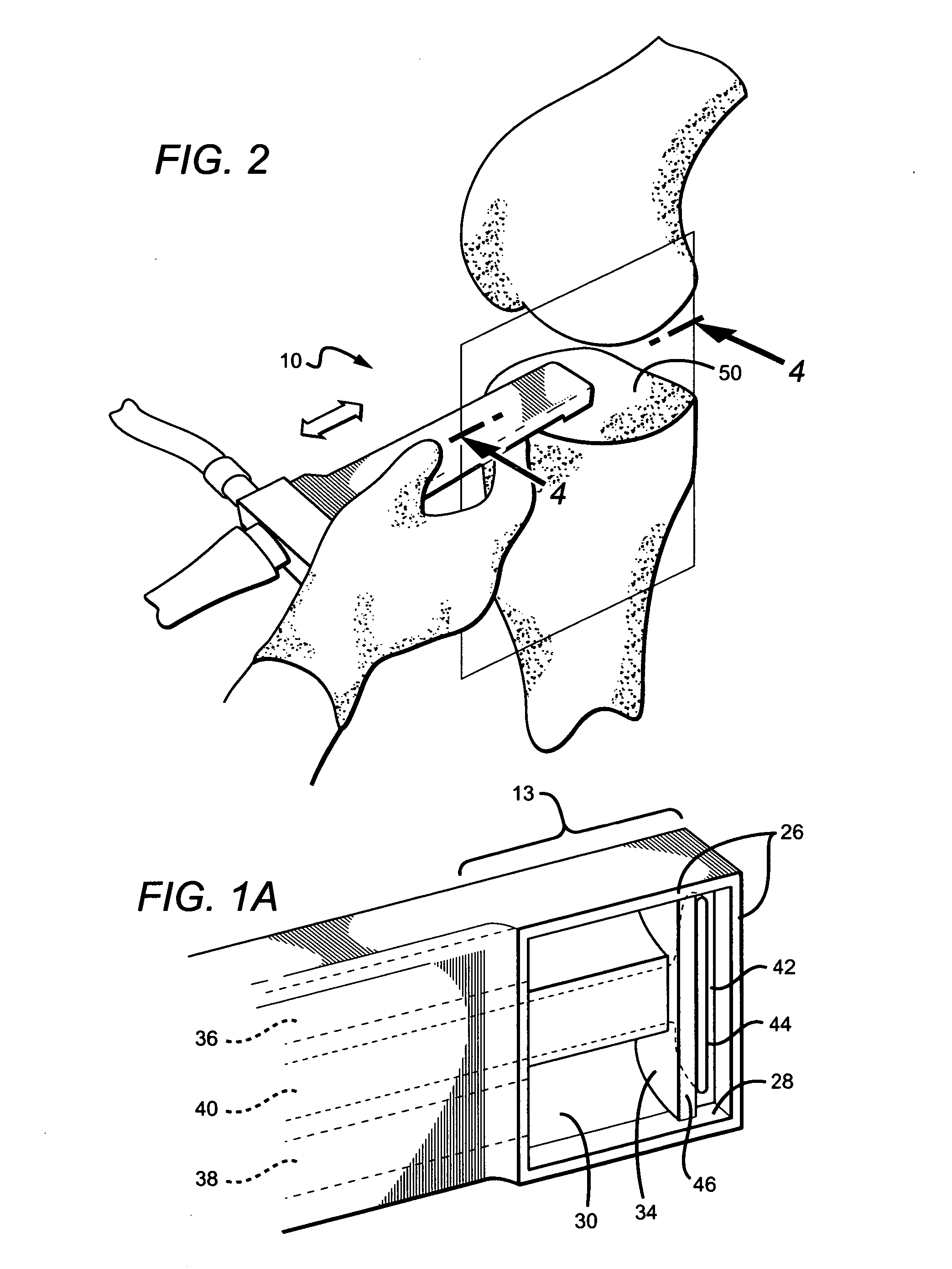

[0026] Some embodiments of the invention will be described in detail with reference to the related drawings of FIGS. 1-4. Additional embodiments, features and / or advantages of the invention will become apparent from the ensuing description or may be learned by practicing the invention.

[0027] In the figures, the drawings are not to scale with like numerals referring to like features throughout both the drawings and the description.

[0028] The following description is not to be taken in a limiting sense, but is made merely for the purpose of describing the general principles of the invention.

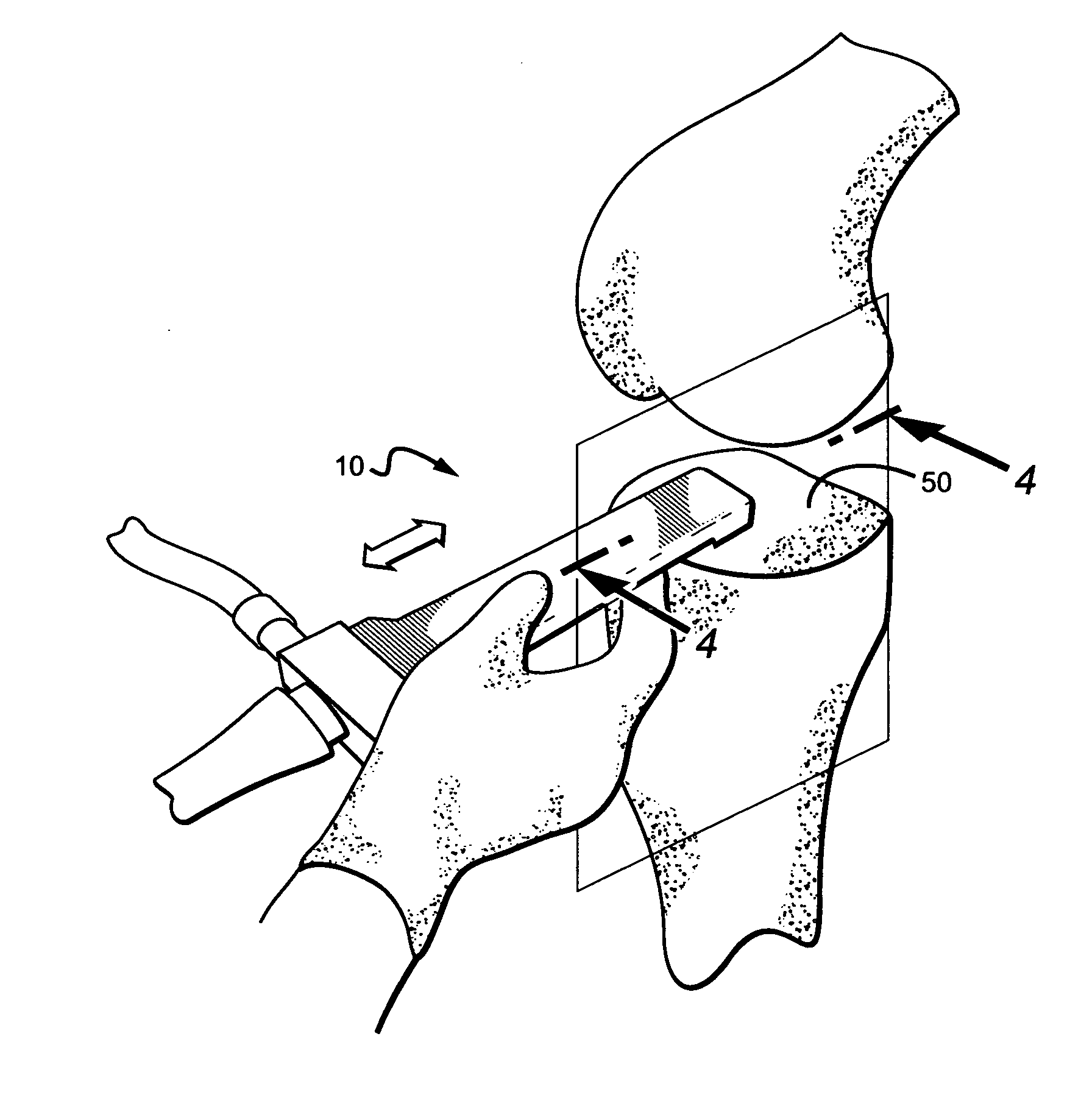

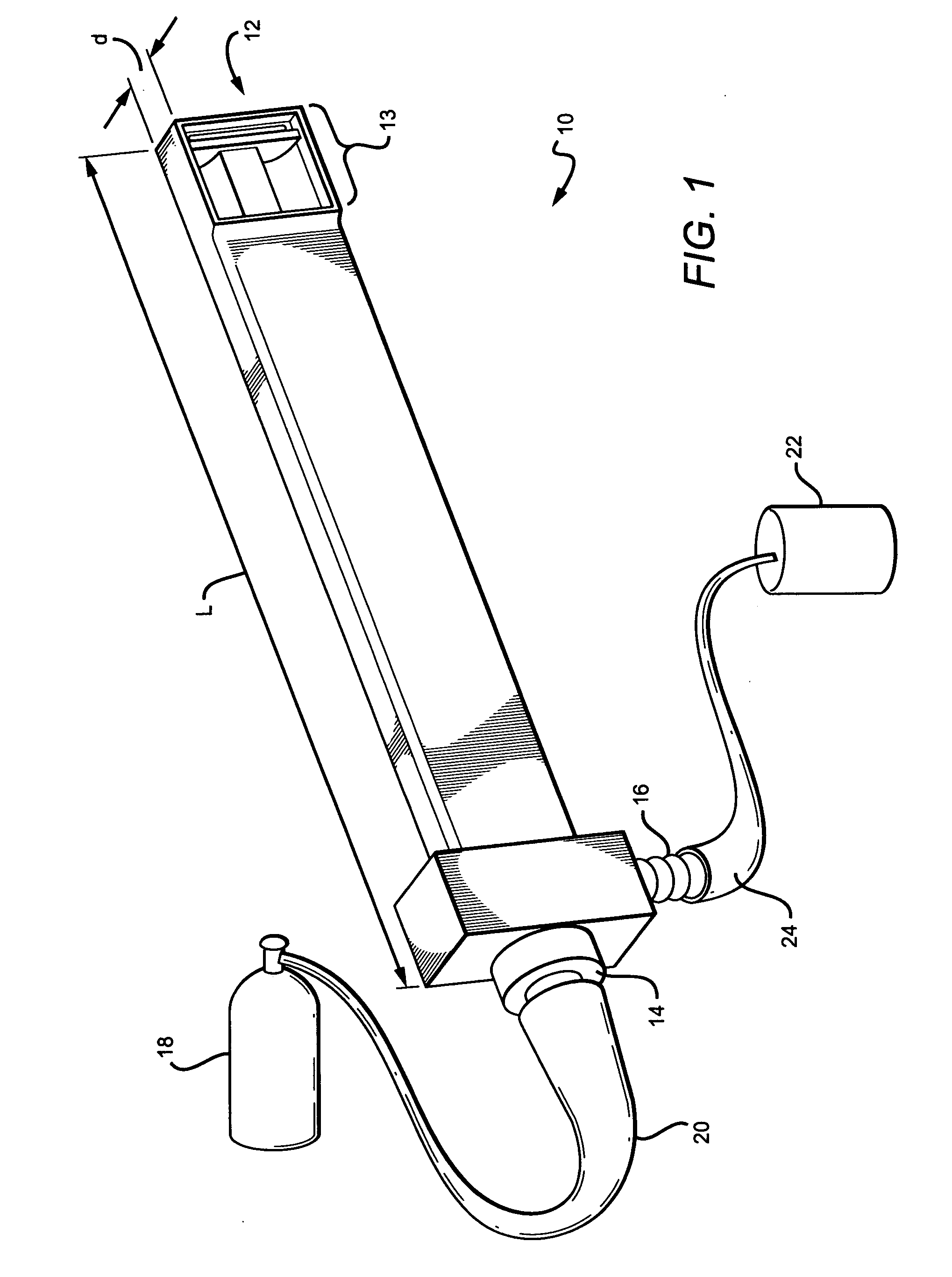

[0029]FIG. 1 is a front perspective view of an apparatus or tool generally referred to by reference numeral 10, adapted for cleaning a surgically prepared working surface in accordance with the present invention. The embodiment of FIG. 1 is particularly well adapted for cleaning a substantially planar bony surface, such as is produced by an oscillating saw in preparation for implantation of a kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com