Coolant pumping device

a pumping device and cooling technology, applied in the direction of pumping, positive displacement liquid engine, machine/engine, etc., can solve the problems of high noise, difficult starting of the rotor in such a condition, and difficult starting of the rotor under such a condition, so as to enhance the operation smoothness improve heat removal efficiency, and enhance the effect of the smooth operation of the pumping devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

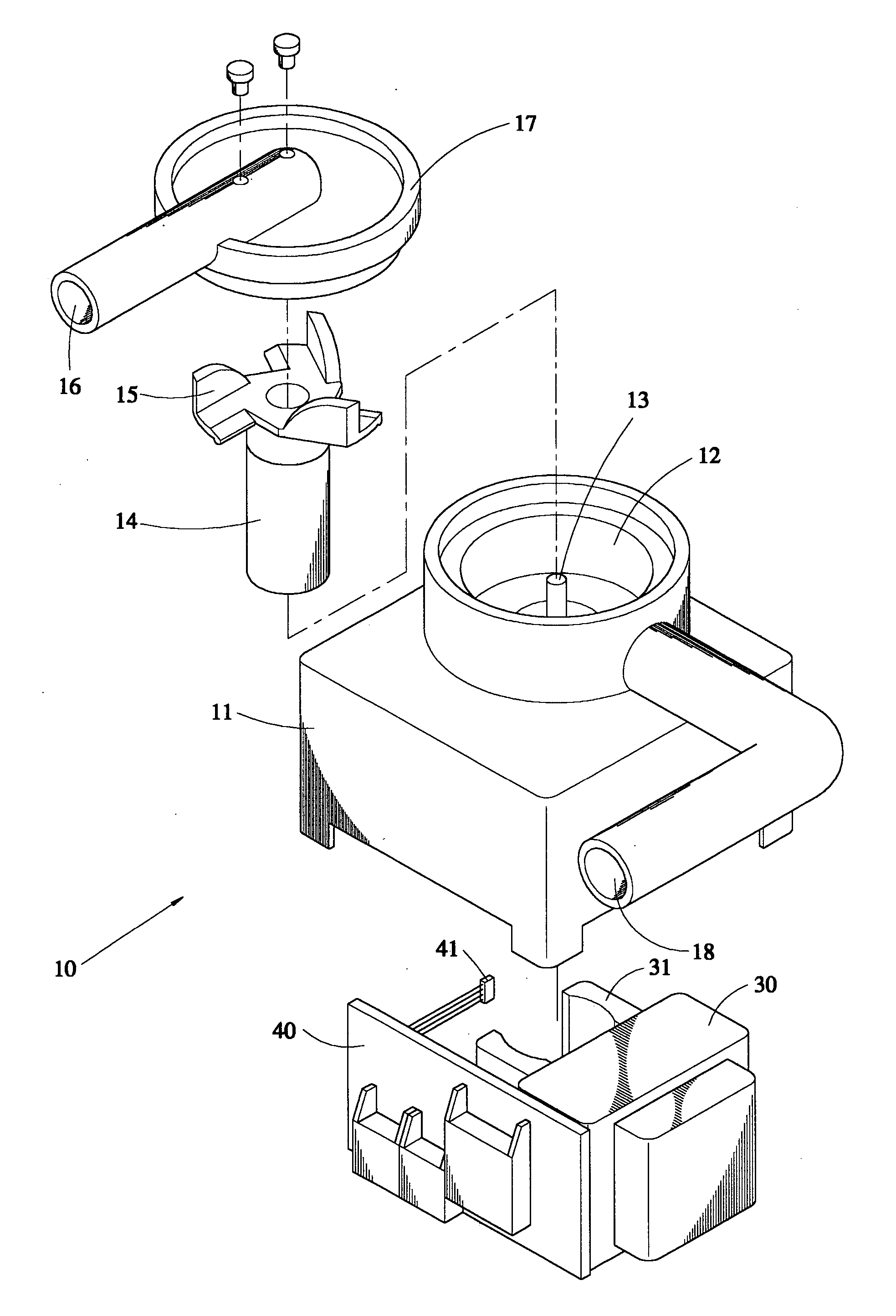

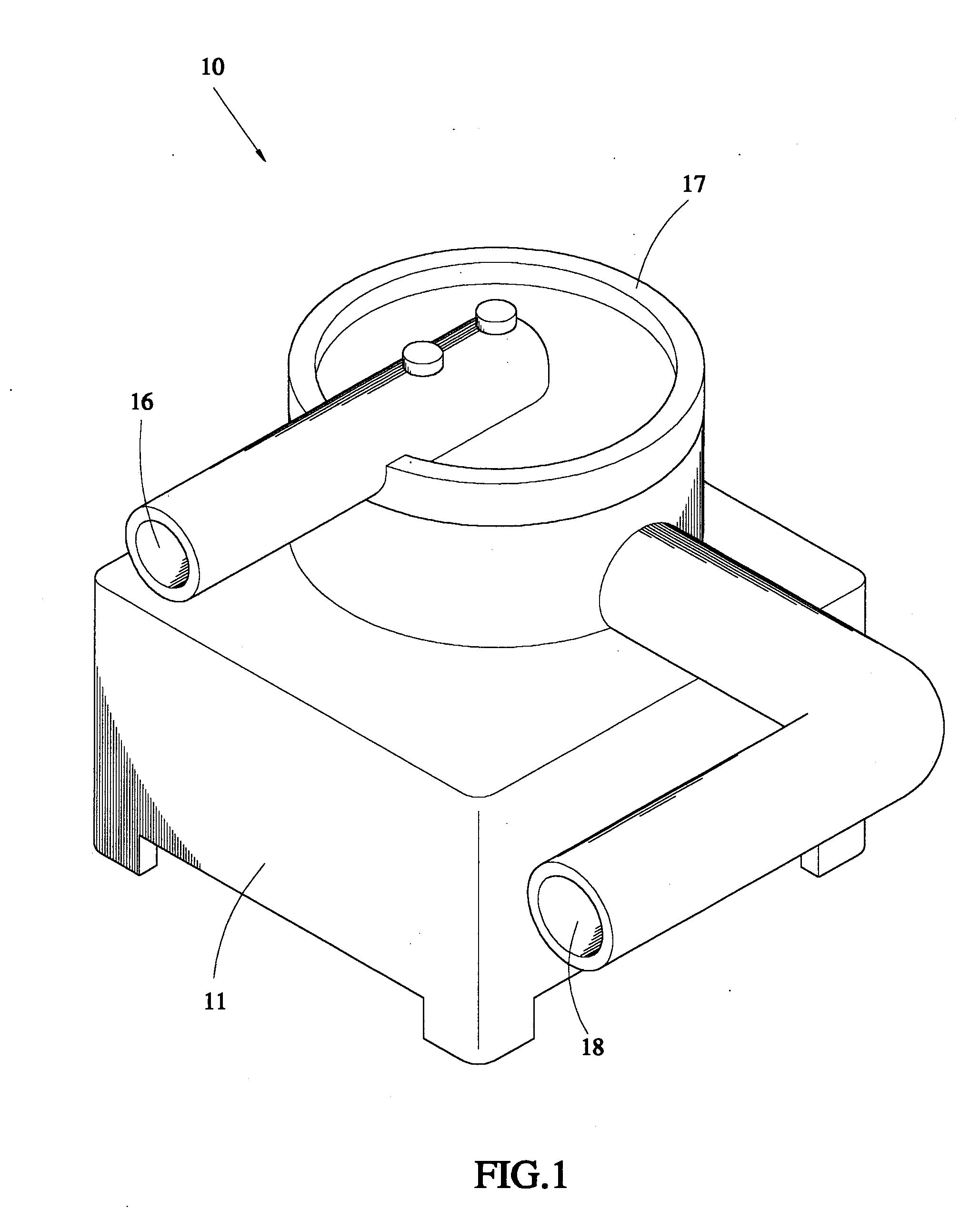

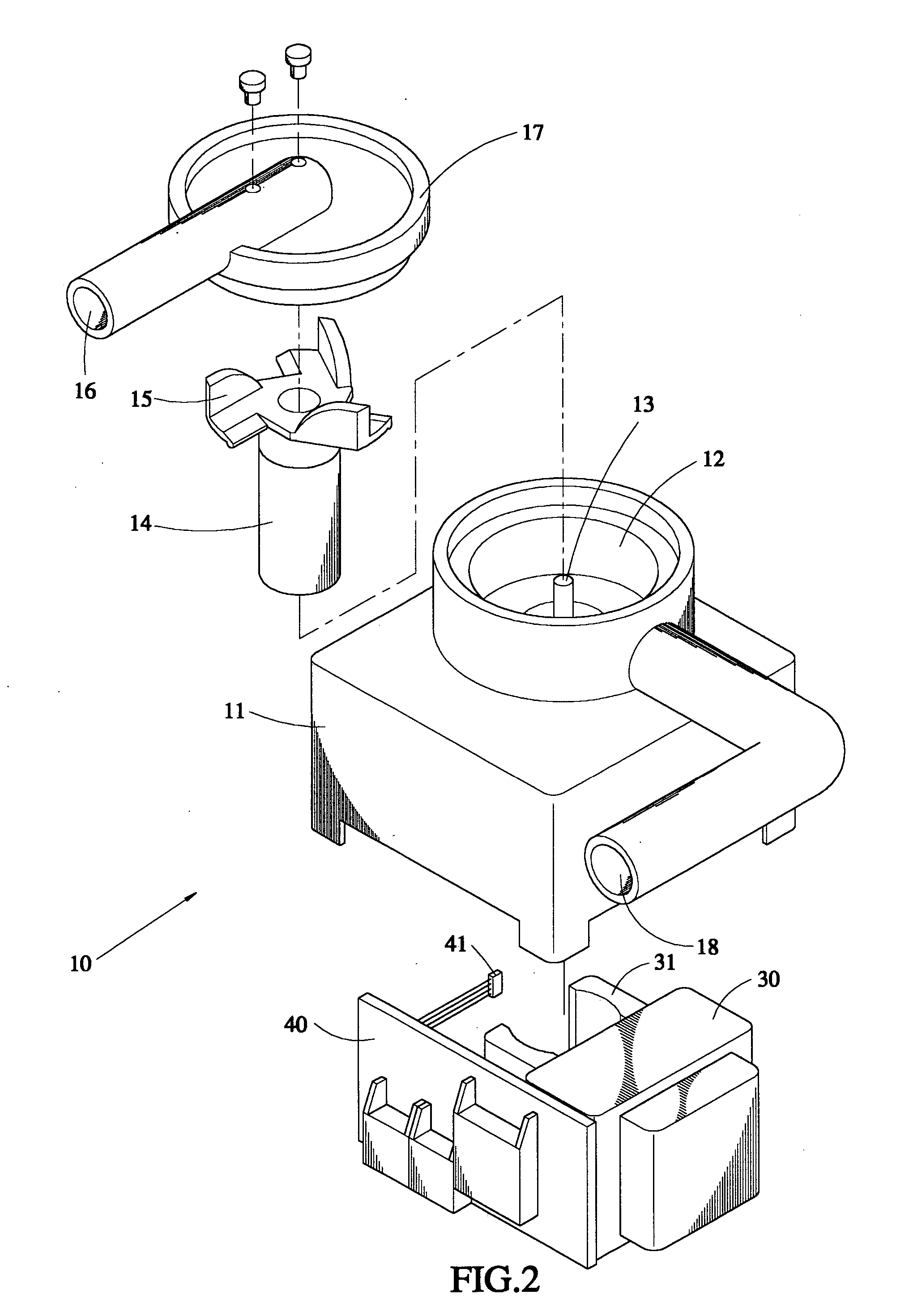

[0016] With reference to the drawings and in particular to FIGS. 1 and 2, which show, respectively, a perspective view and an exploded view of a coolant pumping device constructed in accordance with the present invention, generally designated with reference numeral 10, the coolant pumping device 10 comprises a casing 11 defining an interior space (not labeled) in which parts constituting a stator portion of an electrical motor are arranged, including at least windings 30 and silicon steel plates 31. A circuit board 40 on which a circuit for controlling power supplied to the stator portion is formed is also arranged inside the casing 10 and in electrical connection with the stator portion.

[0017] A first chamber 12 is formed atop the casing 11. In the embodiment illustrated, the first chamber 12 comprises a cylindrical outer wall from which a coolant outlet 18, which in the embodiment illustrated is in the form of a shaped tube in fluid communication with the first chamber 12, extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com