Hand-held pumping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

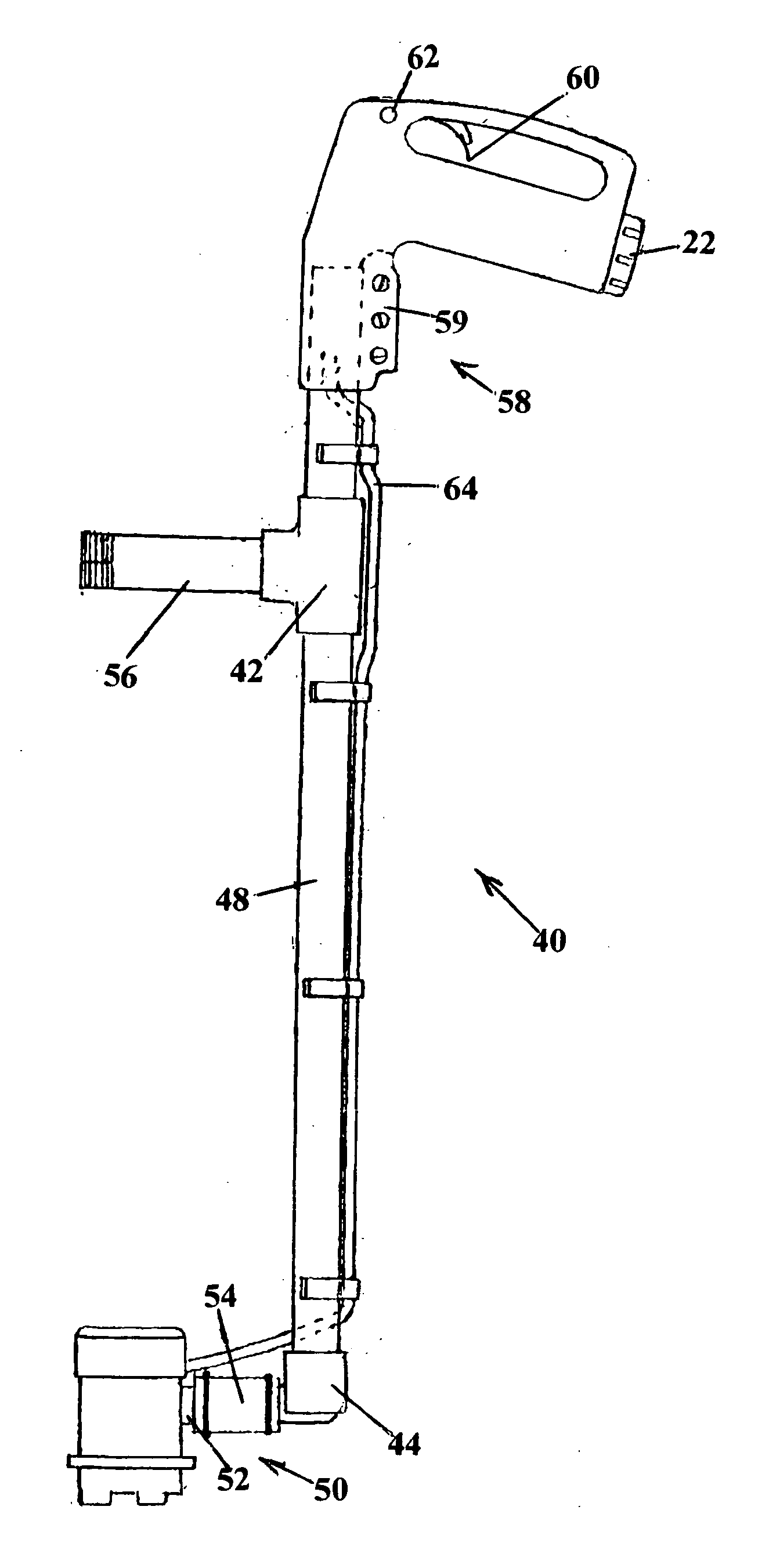

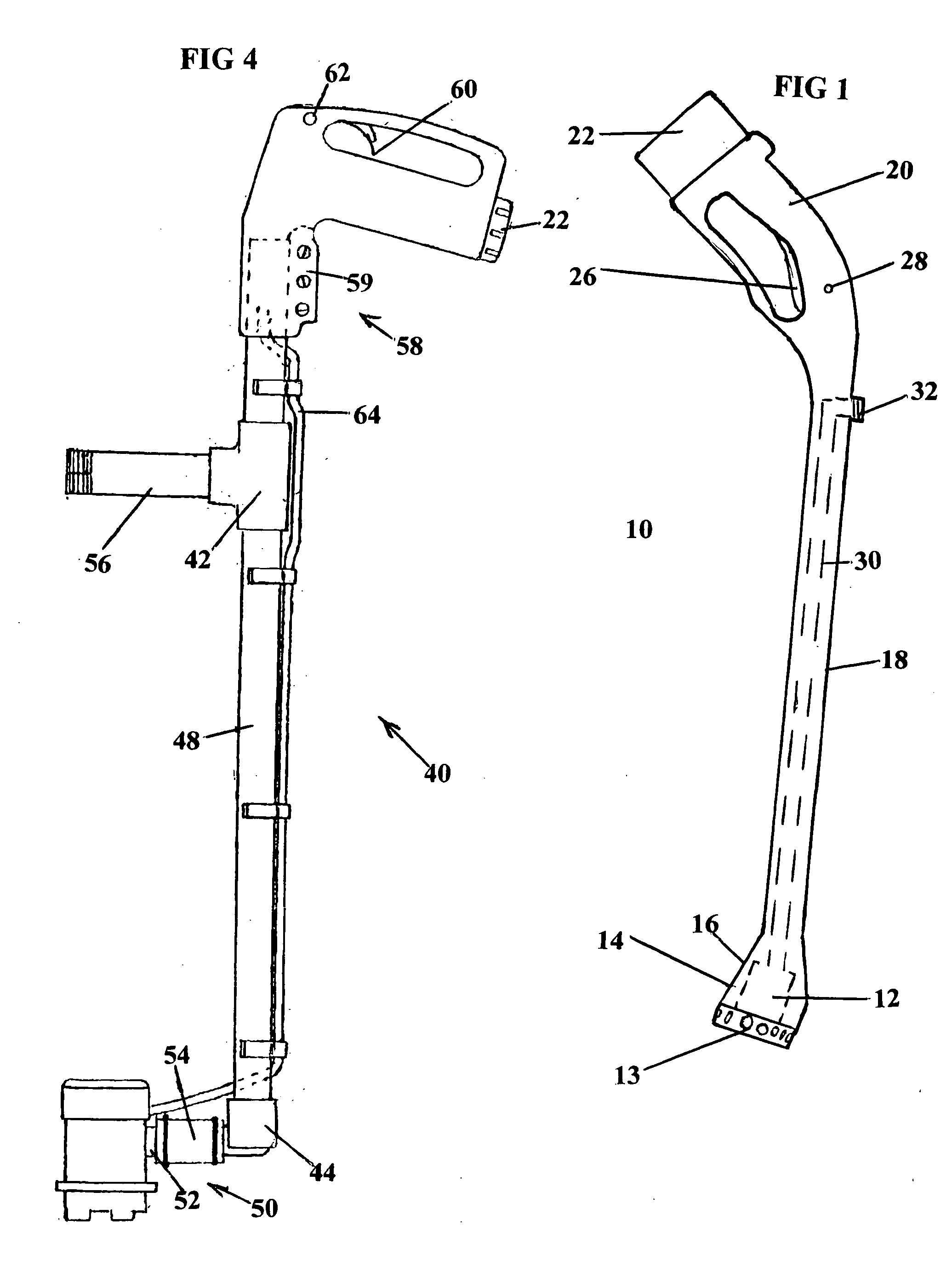

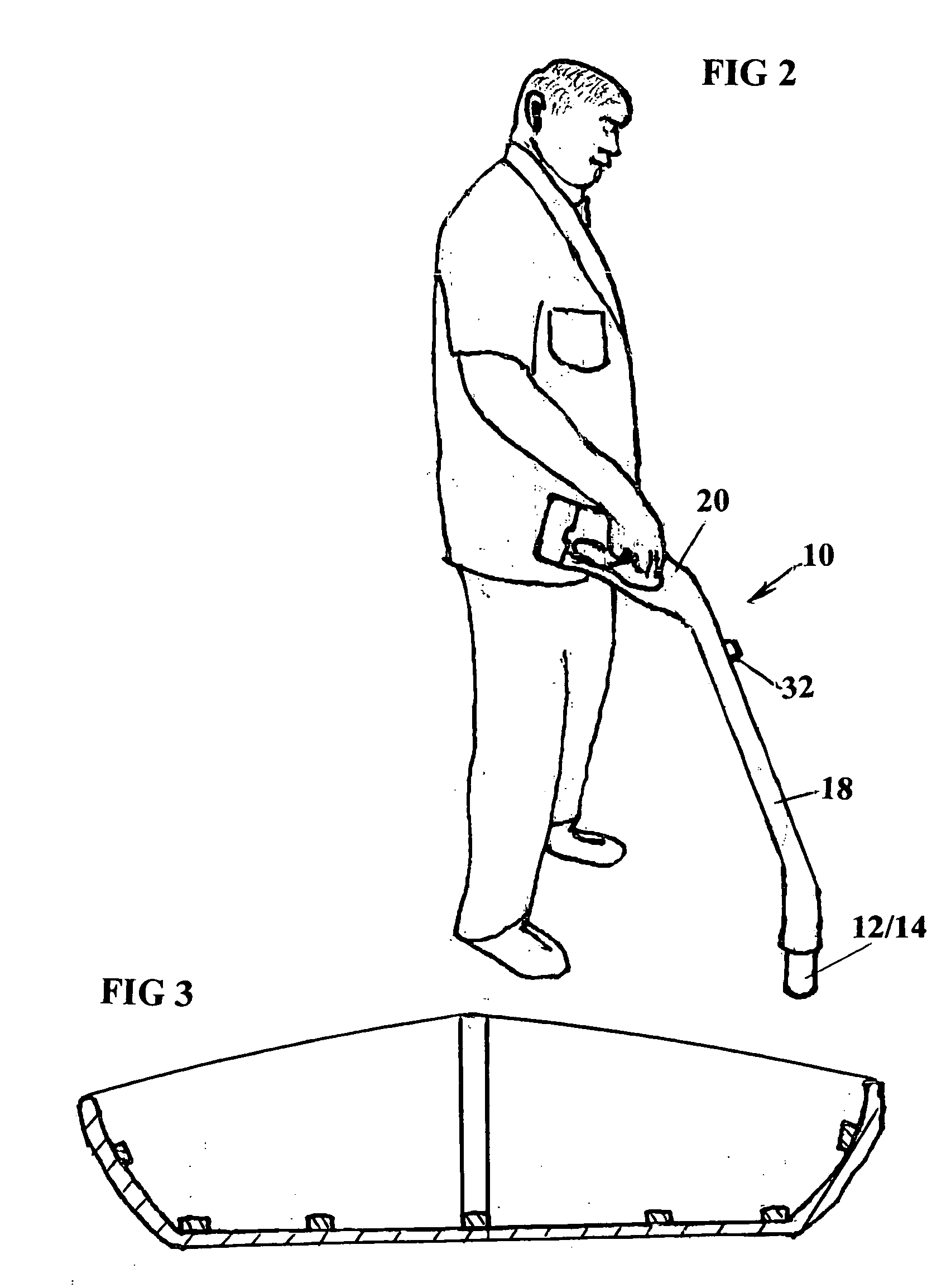

[0026] Referring to FIGS. 1 and 2, a bailer device 10 in accordance with the present invention has a pump portion 12 surmounted by an electric motor 14.

[0027] The pump 12 has a screened filter inlet 13, to exclude detritus that otherwise might jam or otherwise block the pump or the associated discharge flow passages.

[0028] The pump / motor 12 / 14 is mounted within a housing 16 at the end of a hollow shaft 18. The shaft 18 is surmounted by an off-set handle portion 20. A battery pack 22, such as those used in power hand tools, is house within the handle portion 20.

[0029] The handle 20 includes a pivotally mounted switch trigger lever 26, and an associated locking button 28 to lock the lever 26 in an operating or in an inoperative condition.

[0030] The motor 14 is DC (direct current) low voltage, suited for battery operation. The output of pump 12 passes upwardly by way of interior hose connection 30 to a discharge housing 32. The discharge axis of the housing 32 is substantially at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com