Self-propelling cleaner

a self-propelling, cleaner technology, applied in the direction of vacuum cleaners, cleaning equipment, domestic applications, etc., can solve the problems of large dust stuck, inconvenient cleaning, and inability to clean, so as to achieve the effect of facilitating the cleaning of self-propelling cleaners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

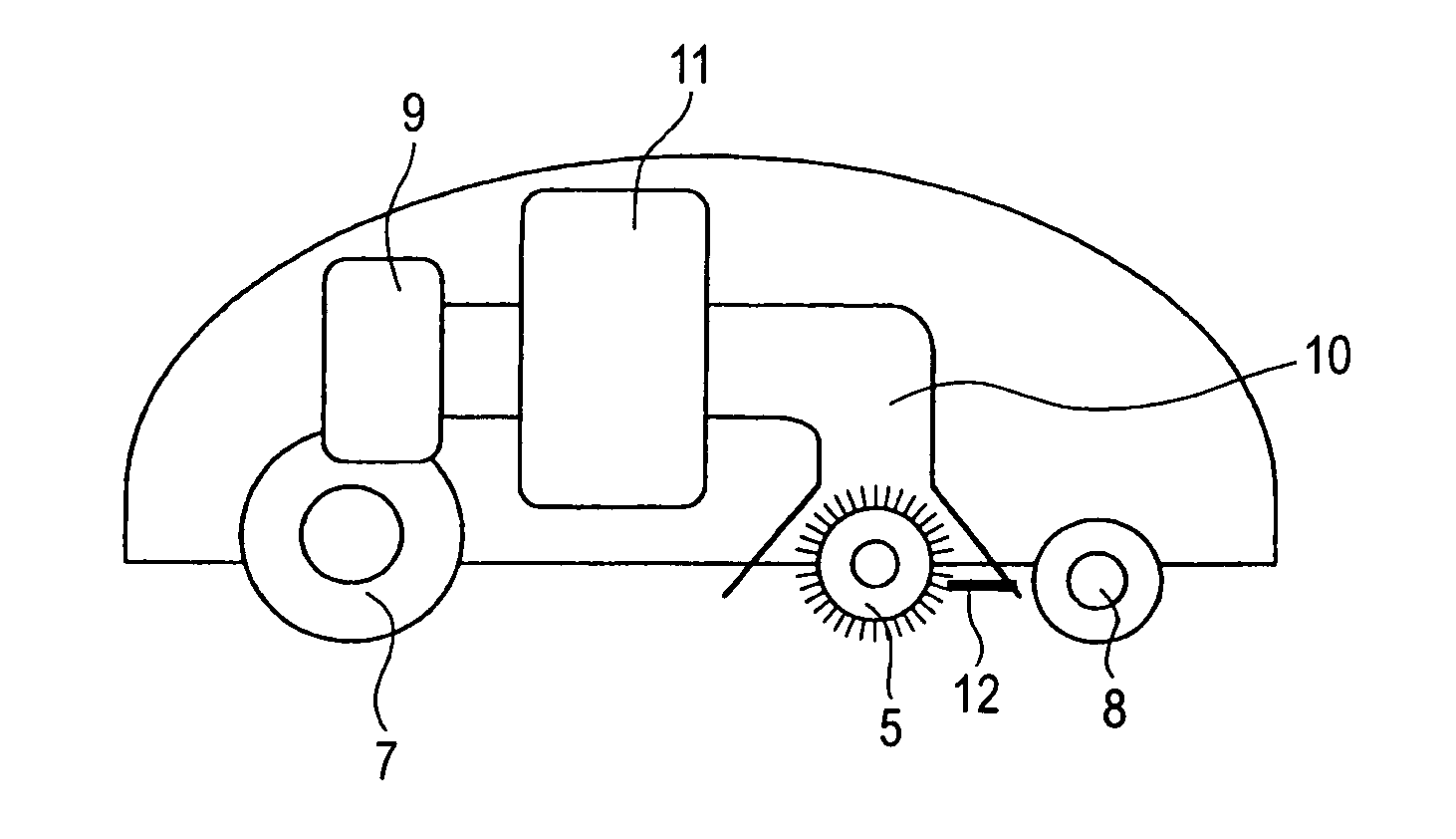

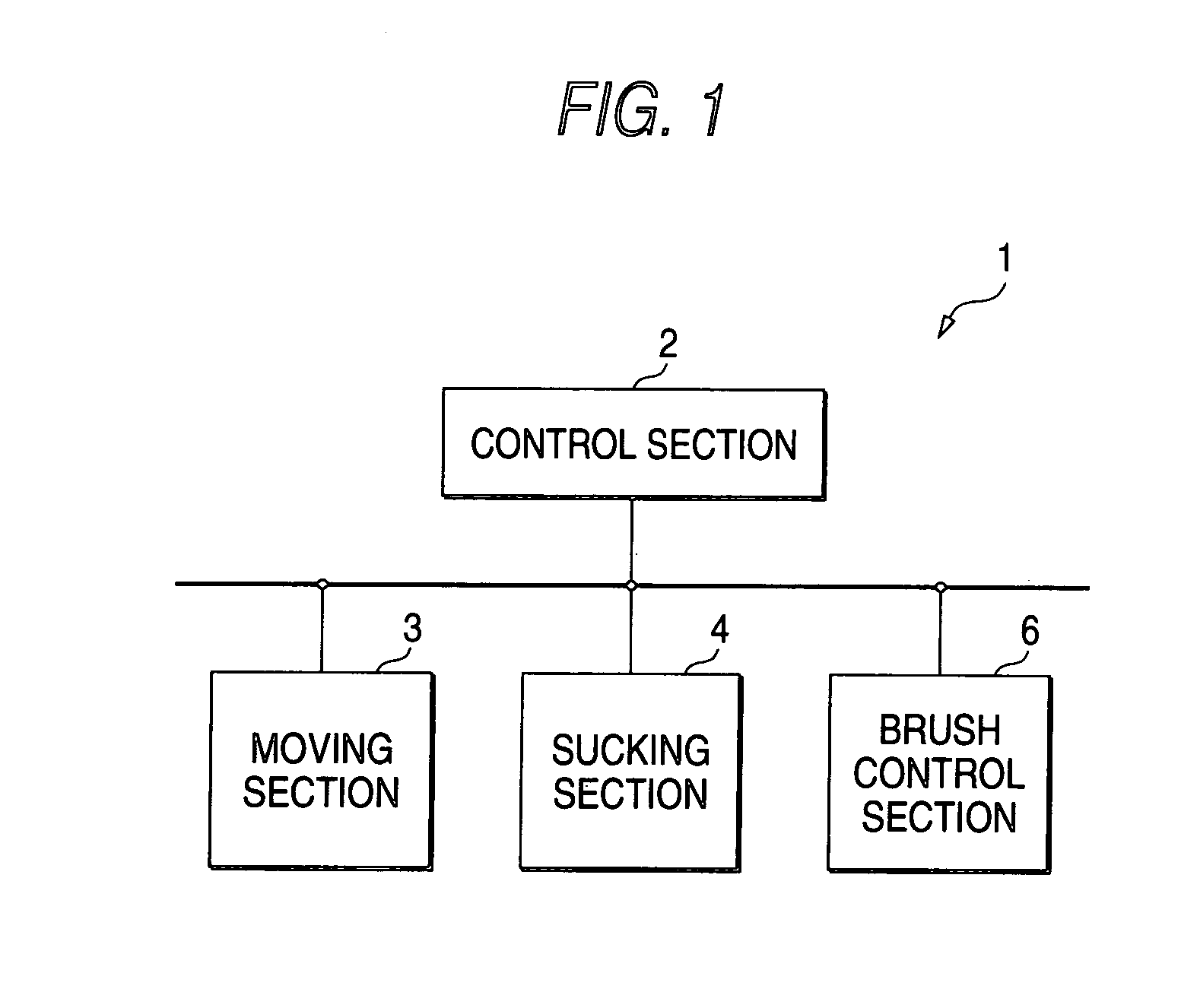

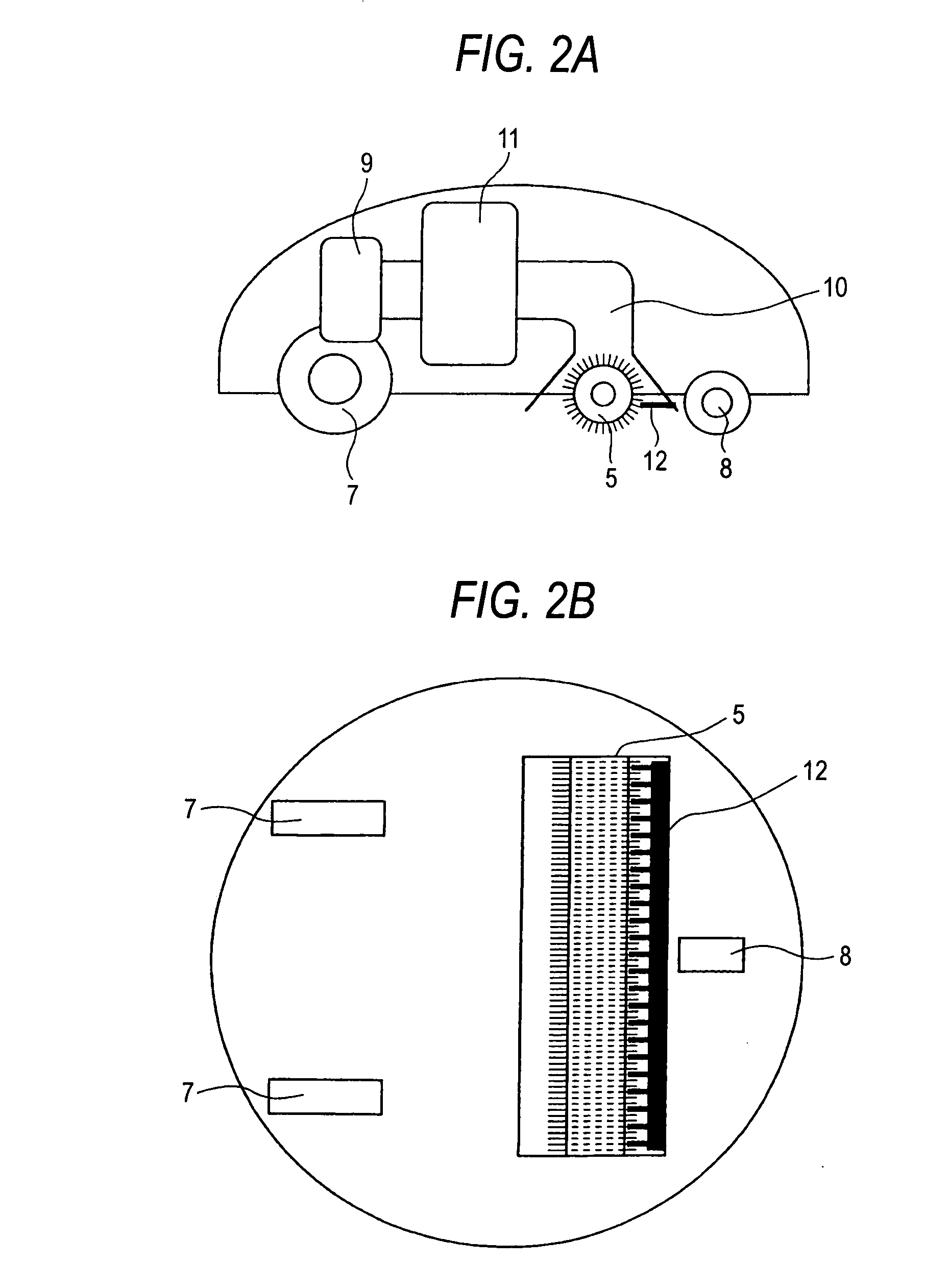

[0015]FIG. 1 is a block diagram showing the configuration of a self-propelling cleaner according to an embodiment of the present invention. FIGS. 2A and 2B are schematic diagrams of the self-propelling cleaner 1 according to the embodiment of the invention; wherein FIG. 2A is a side sectional view and FIG. 2B is a bottom view. The self-propelling cleaner 1 includes a control section 2 for controlling operation of the main body, a moving section 3 for controlling the rotation speeds of tires individually, a sucking section 4 for sucking dust into the main body through a suction mouth that is provided in the main body by rotating a suction fan, and a brush control section (dust removing section) 6 for kicking up dust on a floor or removing dust from a rotary brush 5 that is attached to the suction mouth by controlling the rotation direction of the rotary brush 5. The control section 2 stores a map that contains information indicating along what route the self-propelling cleaner should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com