Shape memory alloy wire driven positive displacement micropump with pulsatile output

a memory alloy wire and micropump technology, applied in the field of compact medical devices, can solve the problem of not cost-effective use of such mechanisms in disposable devices, and achieve the effect of accurate, repeatable and reliable fluid output and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. Overview

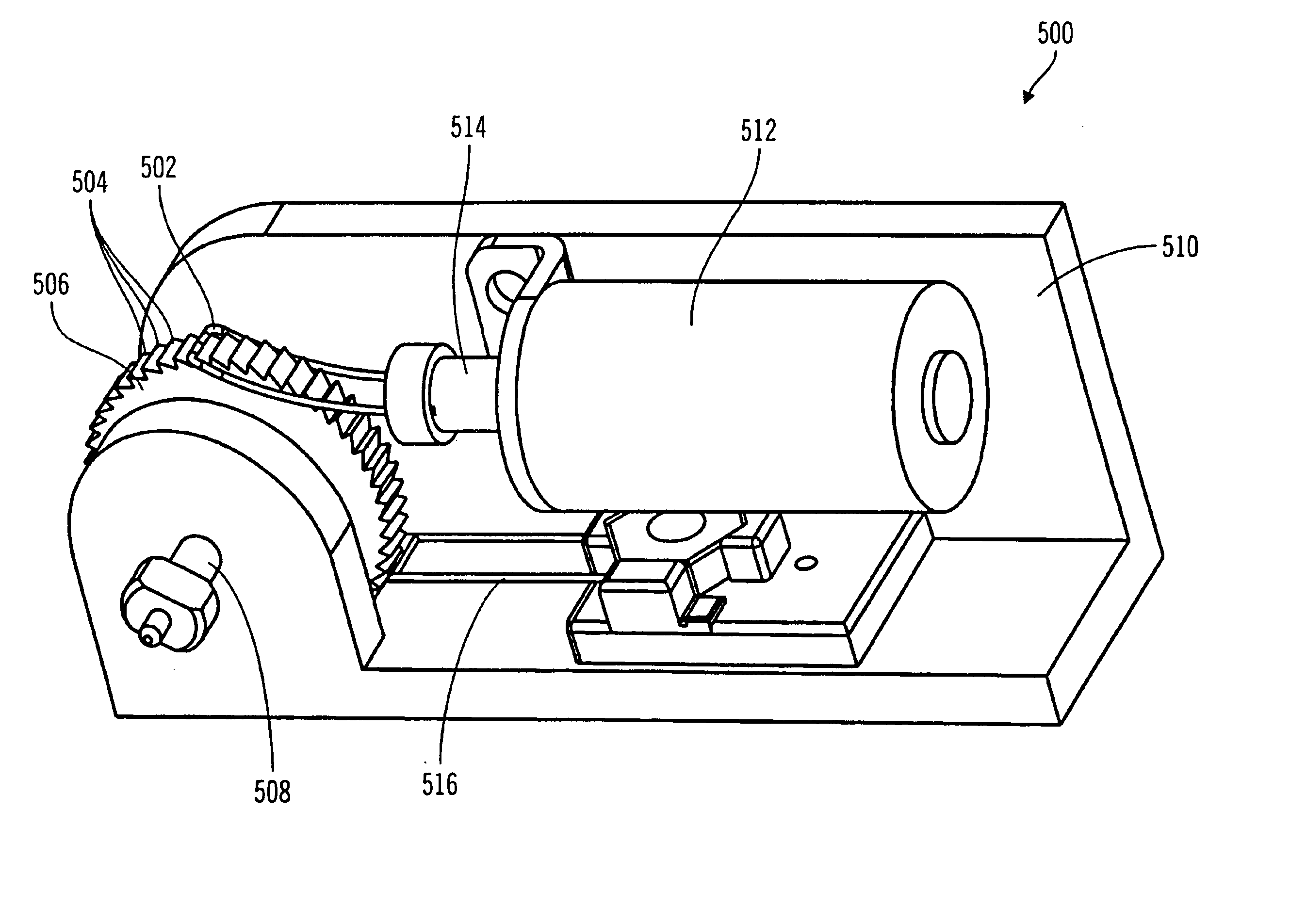

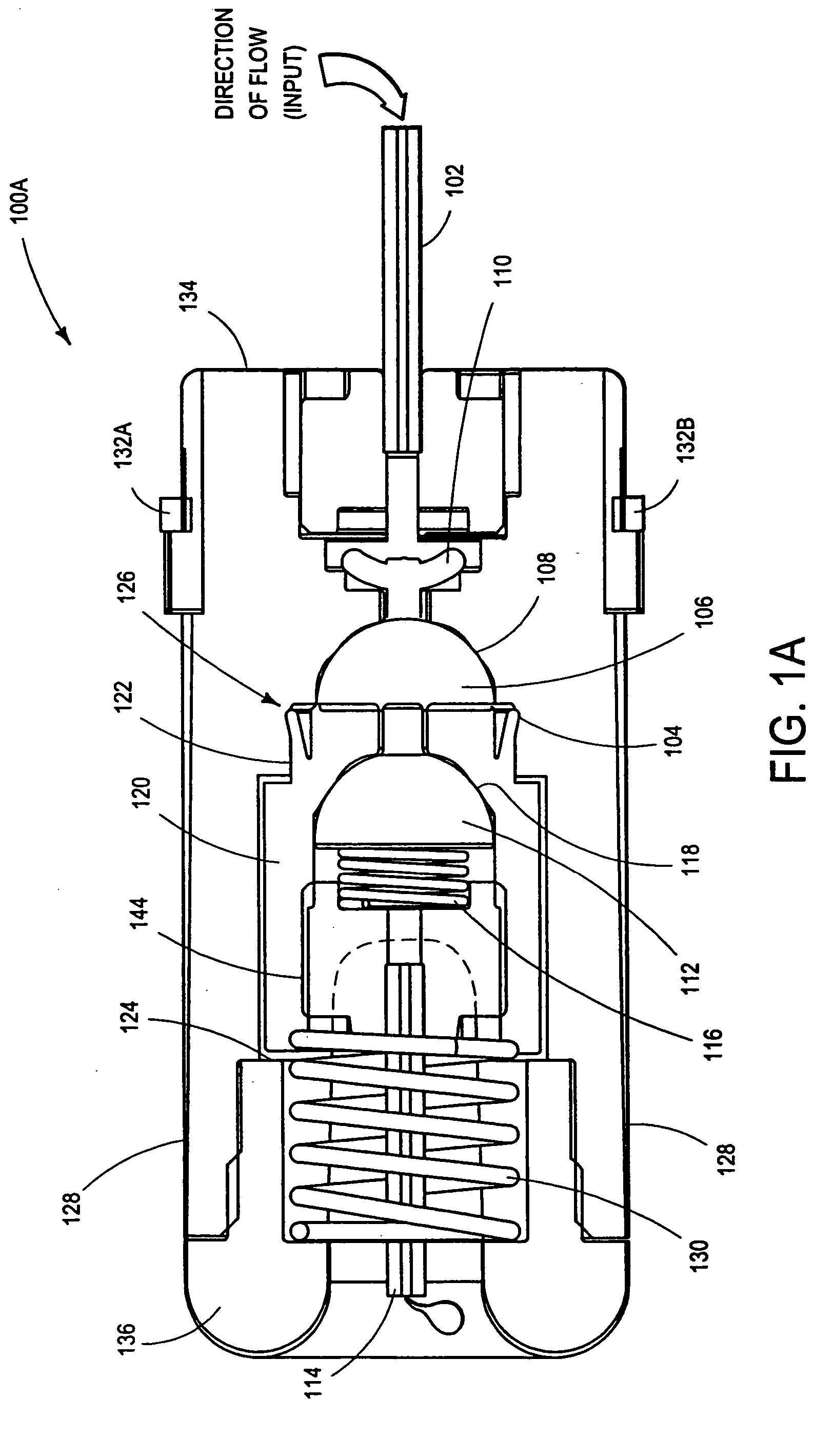

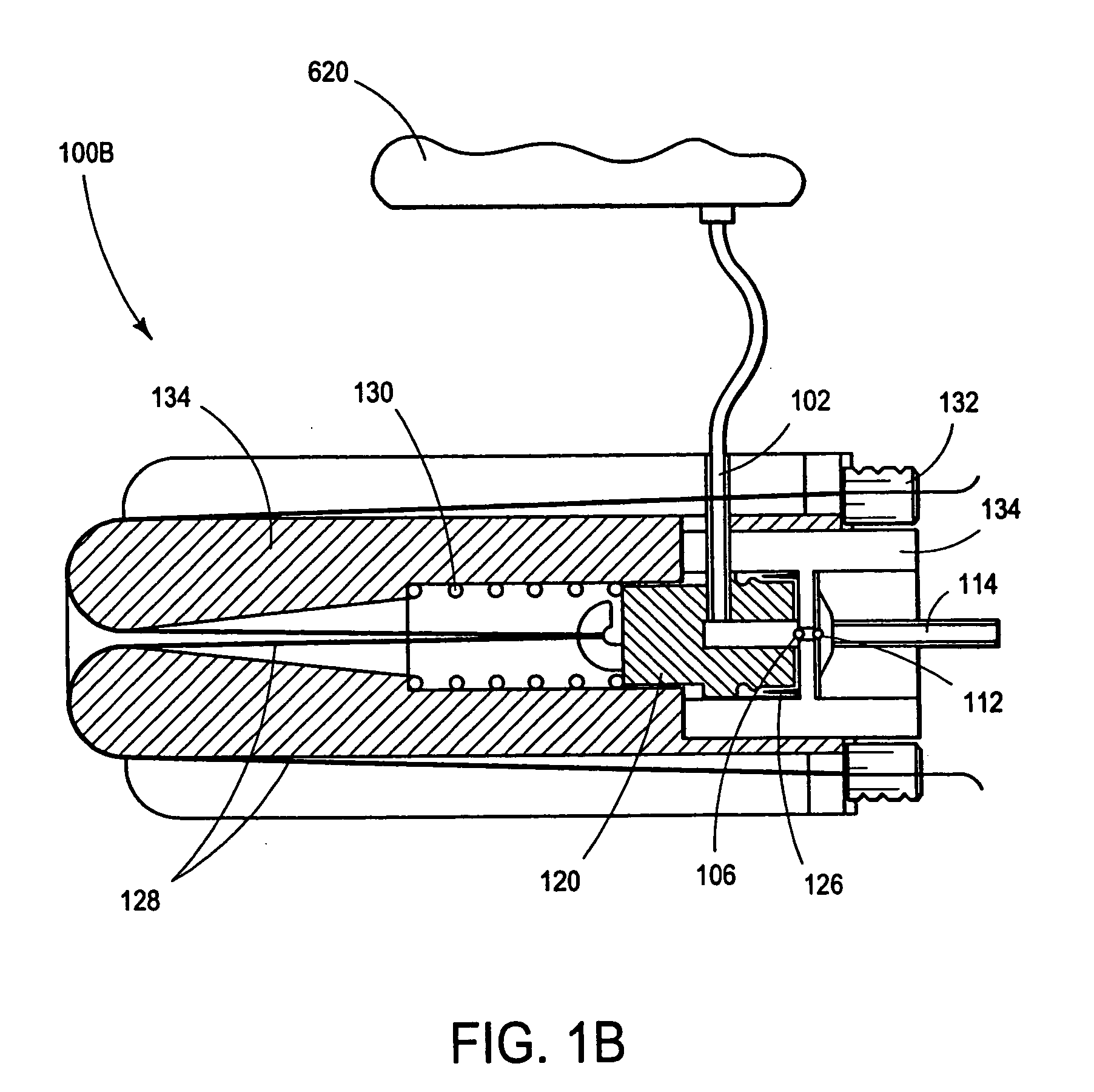

[0029] The invention disclosed herein has a number of embodiments. An illustrative embodiment of the invention disclosed herein is a positive displacement-type miniature pump that employs a mechanism which includes a shape memory alloy (SMA) material. Shape memory alloys are metals known for unusual and dramatic property changes with temperature. Selective alloying of the metal determines a transformation temperature at which the alloy transitions as it is heated from a martensite crystal structure to an austentitite crystal structure. Below the transformation temperature, in the martensitic phase, the alloy is easily deformed in a plastic condition. However, when the alloy is heated to a temperature at or exceeding the transformation temperature, internal stresses drive the alloy to return to the memorized shape in the austentitic phase. During the shape recovery, work energy can also be harnessed at very high stress levels. The “memory” of the alloy is set with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com