Nose pad assembly for eyeglasses

a technology for eyeglasses and nose pads, which is applied in the direction of instruments, spectales/goggles, multi-purpose tools, etc., can solve the problems of wearers that disregard proper safety procedures and fail to wear protective eyewear, and the lens in this construction does not provide free floating ends, so as to reduce complexity and overall assembly steps, the effect of high adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

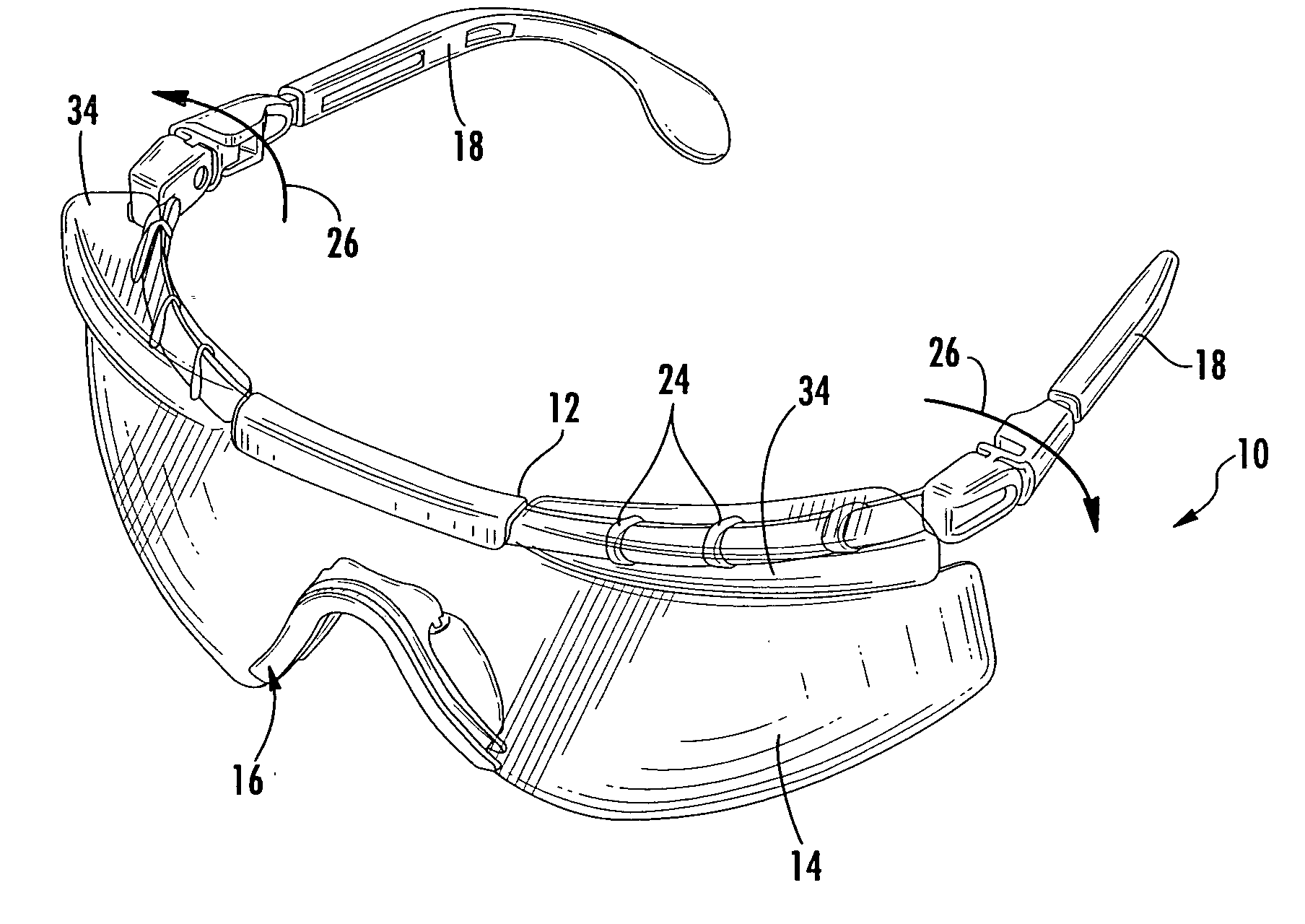

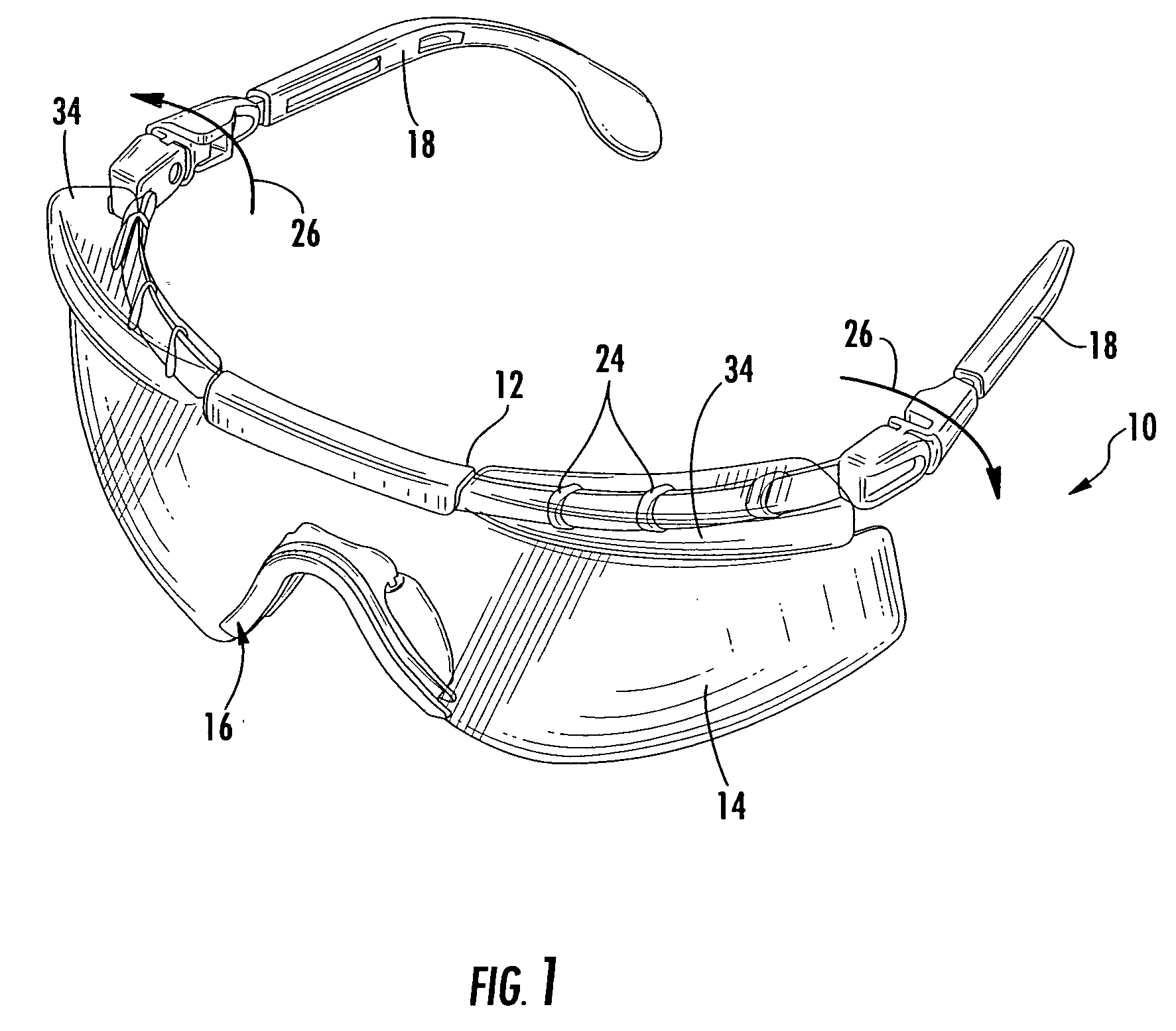

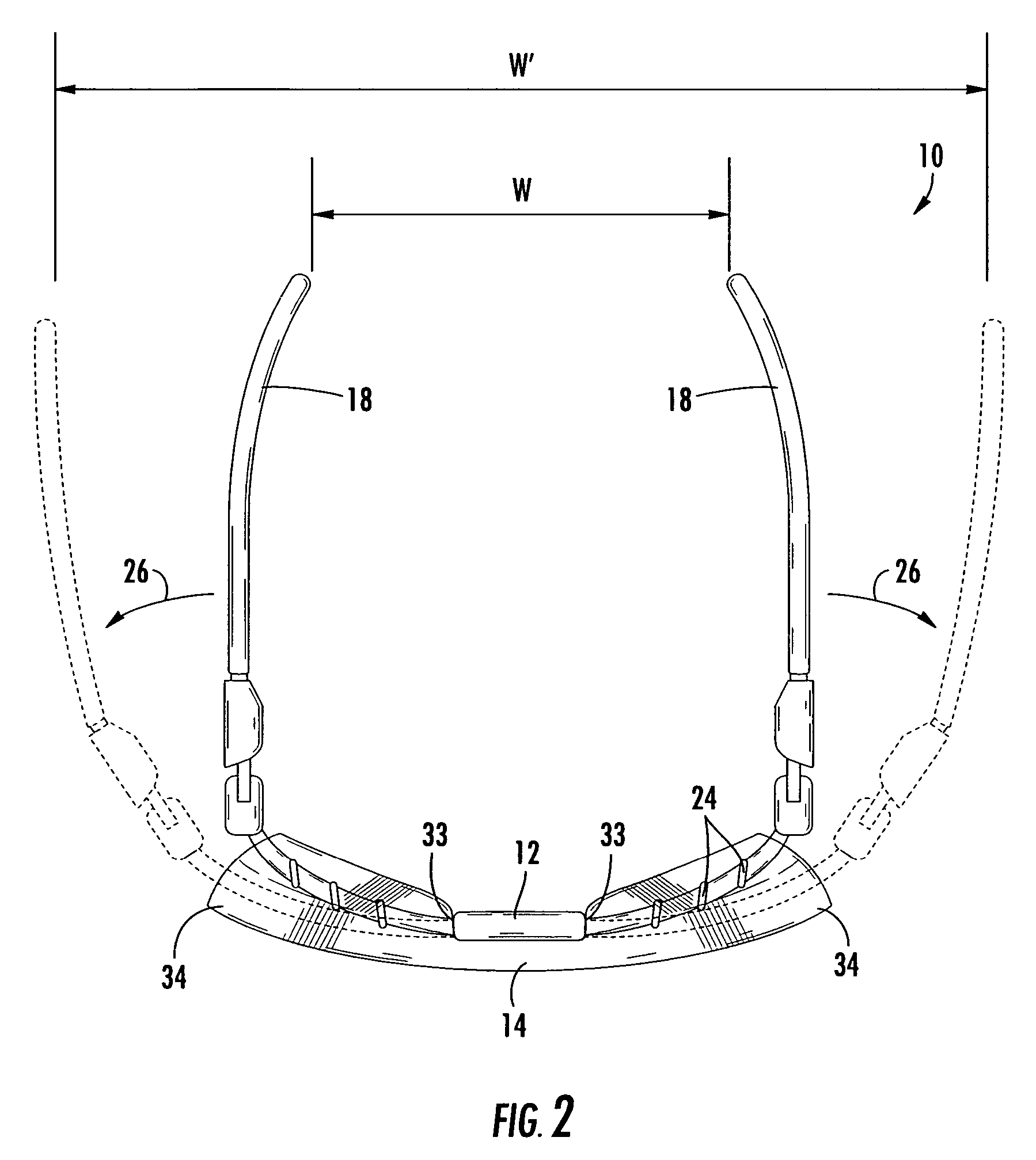

[0033] Now referring to the drawings, a preferred embodiment of the safety eyewear of the instant invention is illustrated and generally indicated at 10 in FIGS. 1-9. As will hereinafter be more fully described, the safety eyewear 10 includes a brow bar 12 that is adapted to receive and support a lens 14, a nose piece 16 that is adapted to be snap received into the nose bridge of the lens 14, and two temple bar assemblies 18 that are snap received into the terminal ends of the brow bar 12.

[0034] The invention utilizes novel multi-shot molding techniques to provide hinge connections and telescoping parts that are formed inside the mold cavity during molding (In-Mold-Assembly or IMA) and thus do not require any additional assembly once the part is removed from the mold cavity. In the preferred embodiment disclosed herein, the molding techniques are particularly important in the formation of adjustable elastomeric nose pads on the nose piece of the eyewear as well as in the integral f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com