Hydraulic dam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

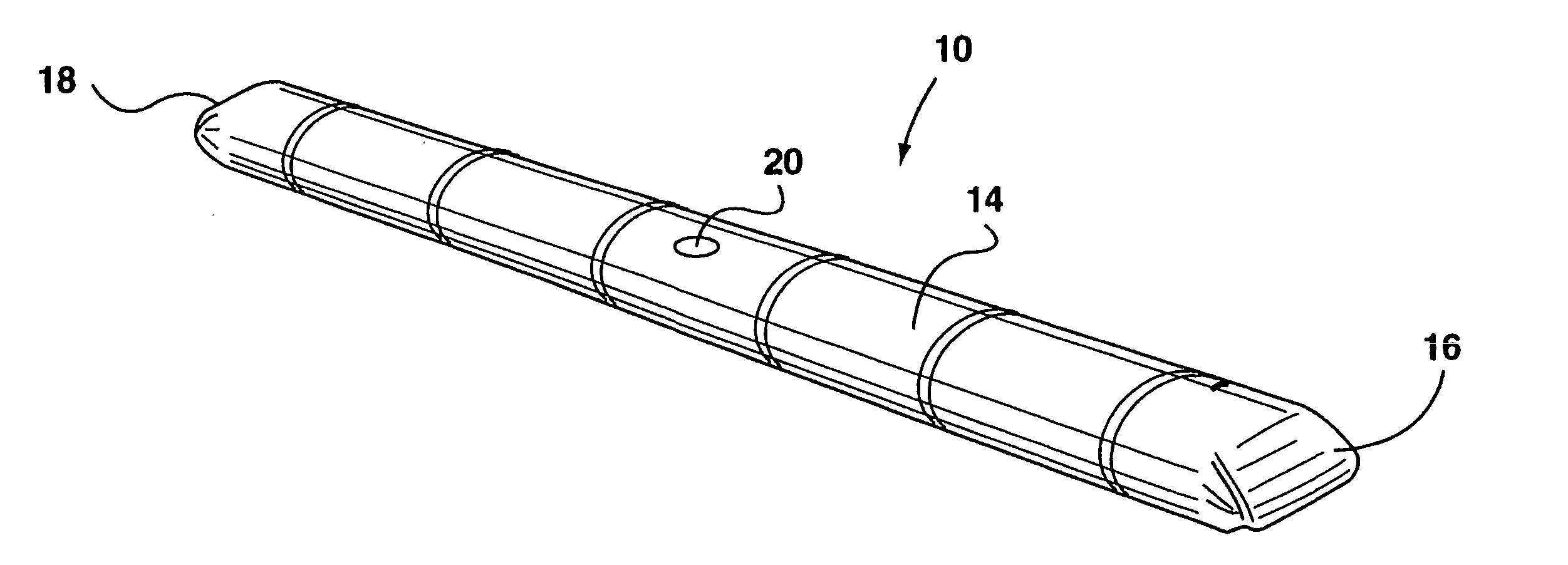

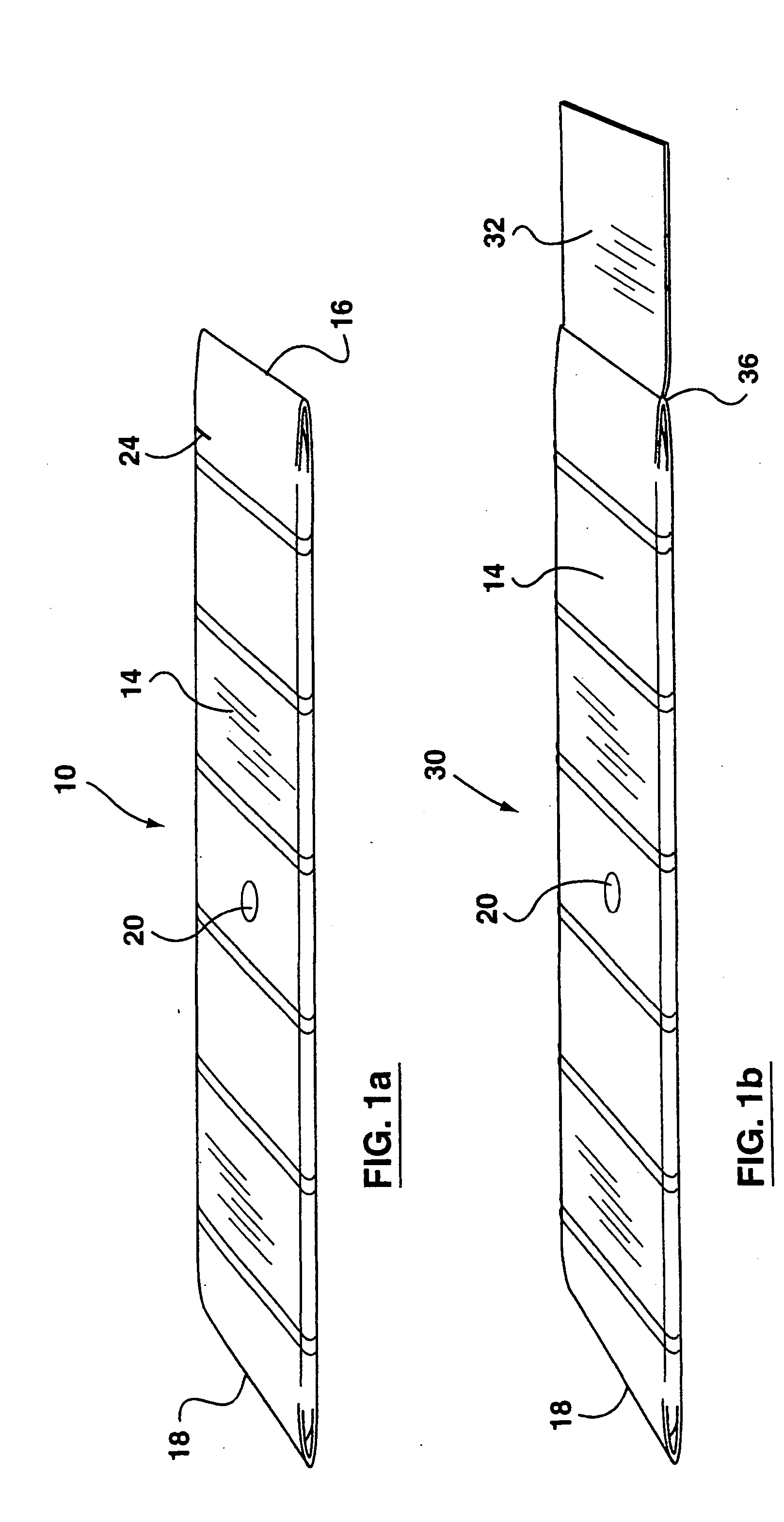

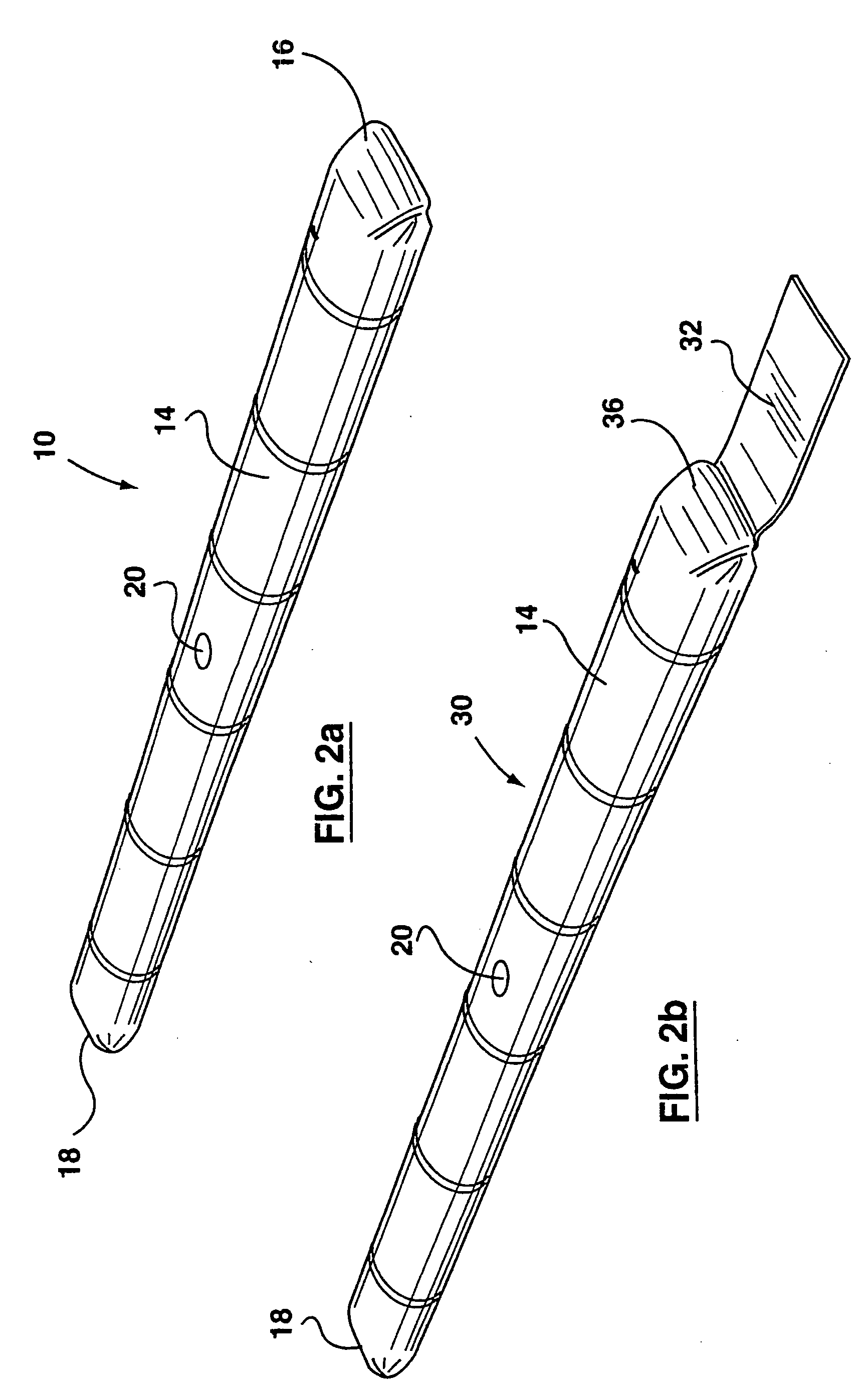

[0019] Referring to FIGS. 1a and 2a, a water fillable barrier 10 has a tubular sidewall 14 and opposed end walls 16 and 18, formed by sealing the tubular sidewall closed at either end. A cap sealed flush mounted port 20 is provided to allow the barrier to be filled or emptied of water. The port may and cap may be threaded so that the cap may thread into the port and seal same. FIG. 1a illustrates the barrier in an empty state and FIG. 2a in a water filled state. The barrier 10 may be made of an impermeable flexible material. A suitable material is a linear low density polyethylene (LLDP) material such as POLYFLEX III™ produced by PolyFlex, Inc. of Grand Prairie, Tex. An advantage of an LLDP is that it has no plasticisers which rodents consider as a food. A further advantage is that the material is chemically resistant.

[0020] While a range of barrier dimensions may be suitable, exemplary dimensions for an empty barrier intended to form the base of a water barrier wall are 11′ (3.35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com