Method and apparatus for cartridge identification imprinting in difficult contexts by recess protected indicia

a cartridge identification and recess protection technology, applied in the field of identification of firearms cartridges, can solve the problems of obscuring the ballistic finger print or scratching evidence on the bullet or cartridge case, being pseudo-repeatable and largely random in nature, and being unable to identify the cartridg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A. Introduction

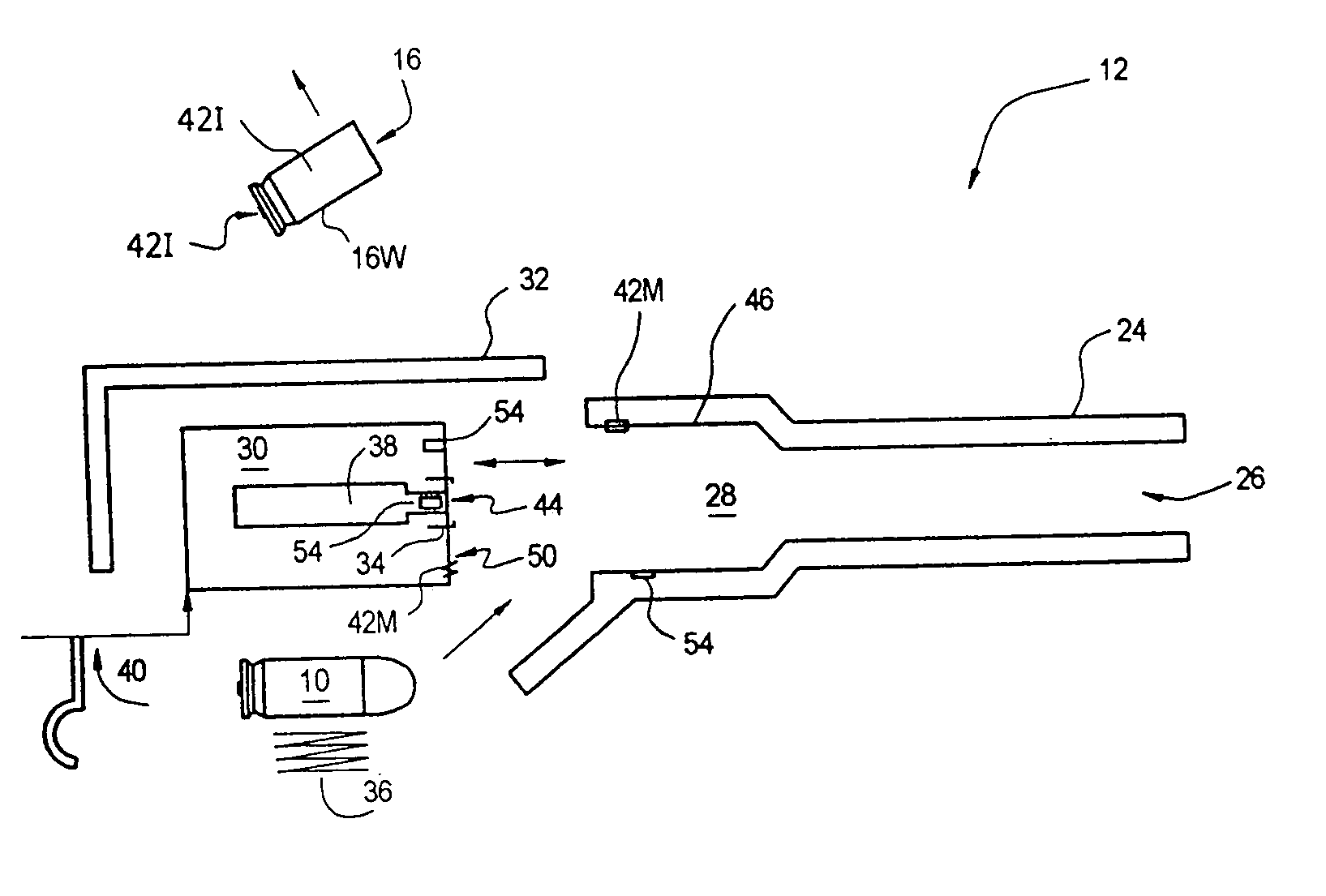

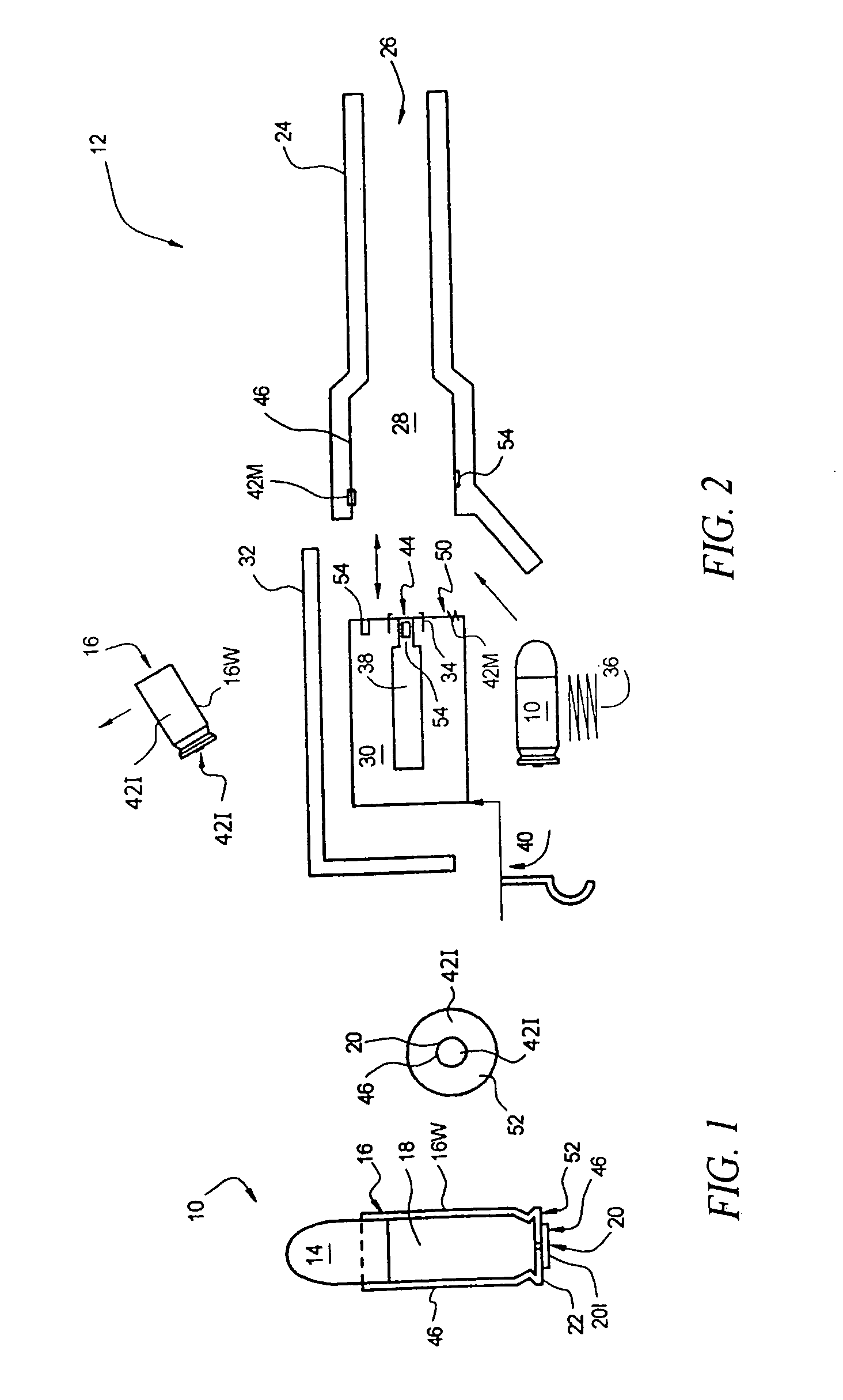

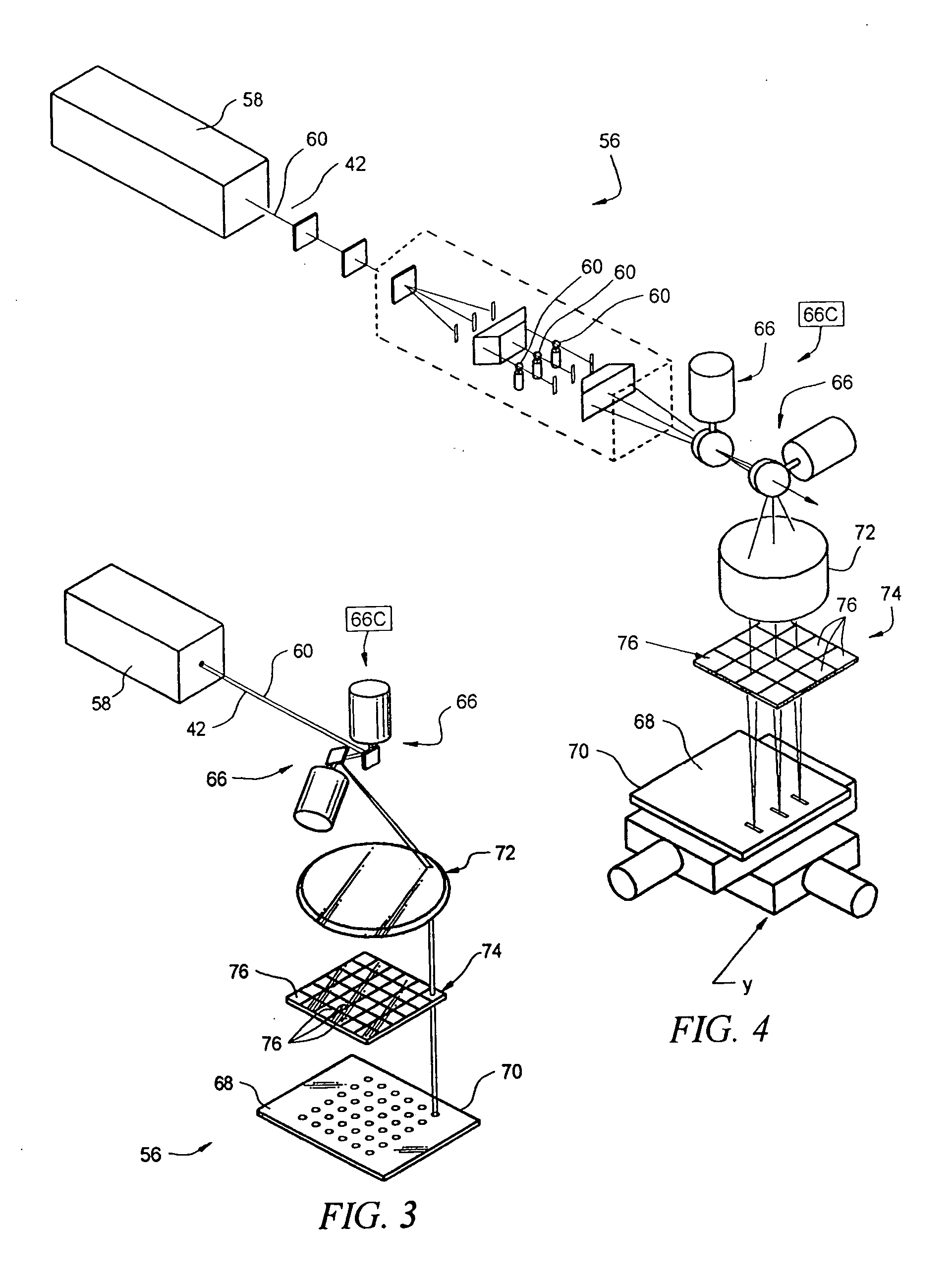

[0040] The following will first discuss the elements and operation of a typical firearm, cartridge and bullet, by way of a general introduction to parts and operations of a firearm in imposing identifying indicia on bullets or cartridge cases and to establish common definitions and points of reference. The following will then provide an introduction to the methods and apparatus for embossing or imprinting identifying indicia by a firearm on a cartridge case or bullet, following by a discussion and description of a laser system for generating or providing, on a part of a firearm, the “micro-engraving” or “micro-stamping” tool or image necessary to emboss or stamp an identifying indicia or a cartridge case or bullet.

[0041] Given foundation descriptions of the technology involved in and related to the present invention, the following will then describe the present invention and presently preferred embodiments of the invention, including presently preferred forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com