Pistol with loaded chamber indicator

a technology of loaded chamber and indicator, which is applied in the field of pistols, can solve the problems of not readily noticeable indicators, difficult for pistol users to visually distinguish loaded chamber conditions from empty chamber conditions by using such devices, and may not be practical or possible to open the chamber and observe the loaded condition of the same. the effect of noticeabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

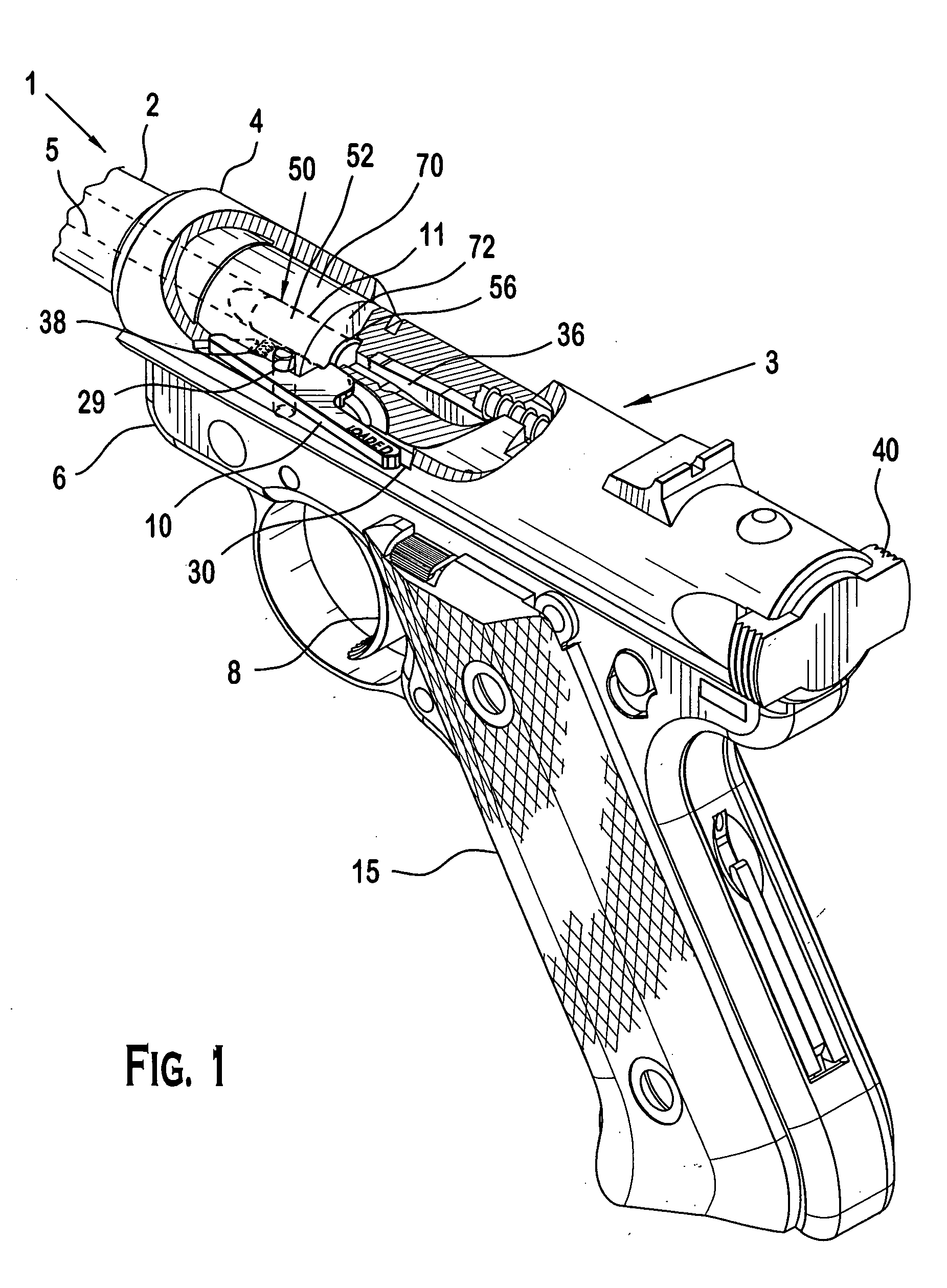

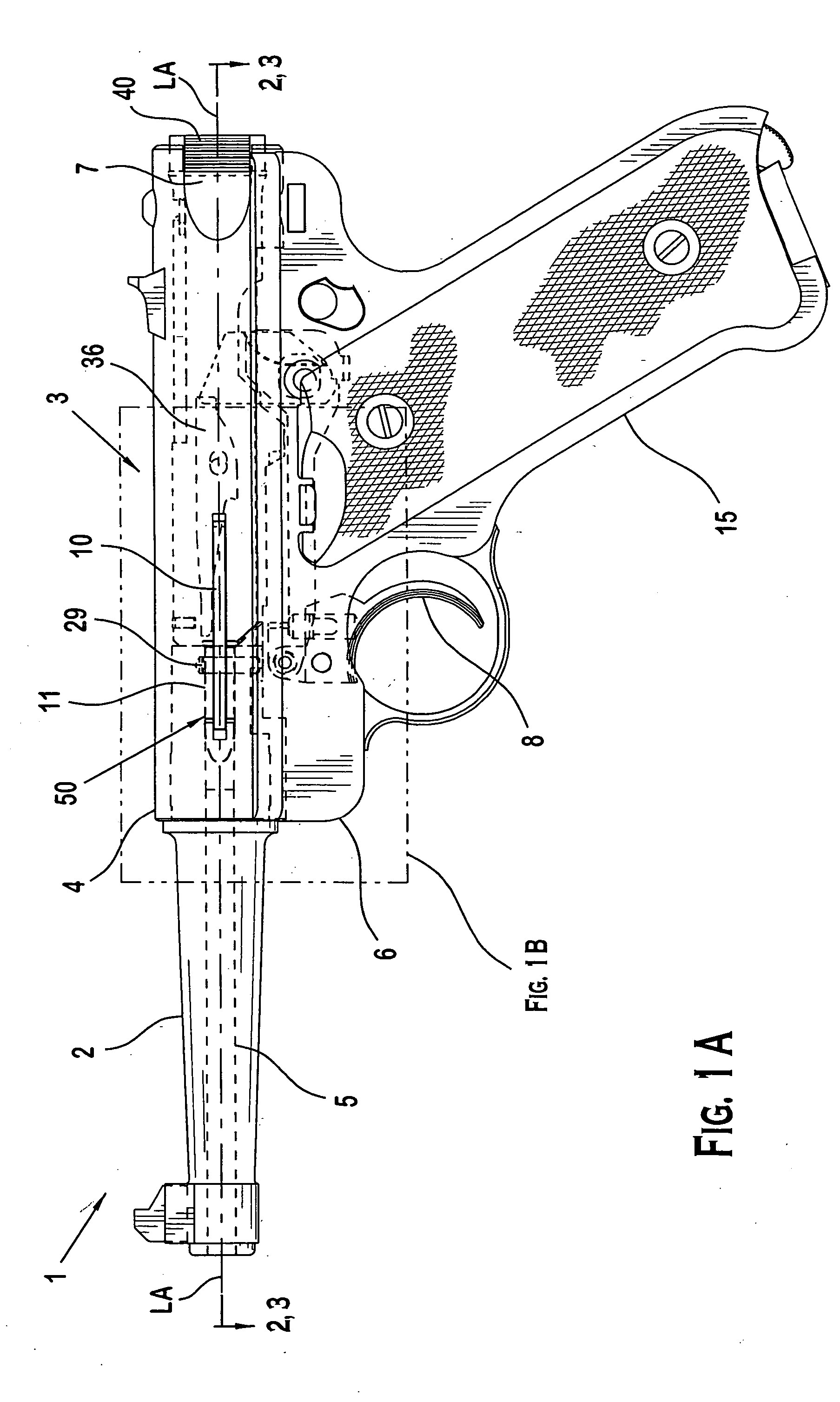

[0037] Referring generally to FIGS. 1-3, a preferred embodiment will now be described for convenience with reference to a rimfire-type pistol in the form of an autoloading pistol. It will be appreciated that the preferred embodiment is equally applicable for use with other type pistols including, without limitation, non-autoloading pistols, centerfire-type cartridge firing pistols, etc. In addition, the preferred embodiment may be used in non-firearm applications where a tactile and visual indication of a component operating position is desired.

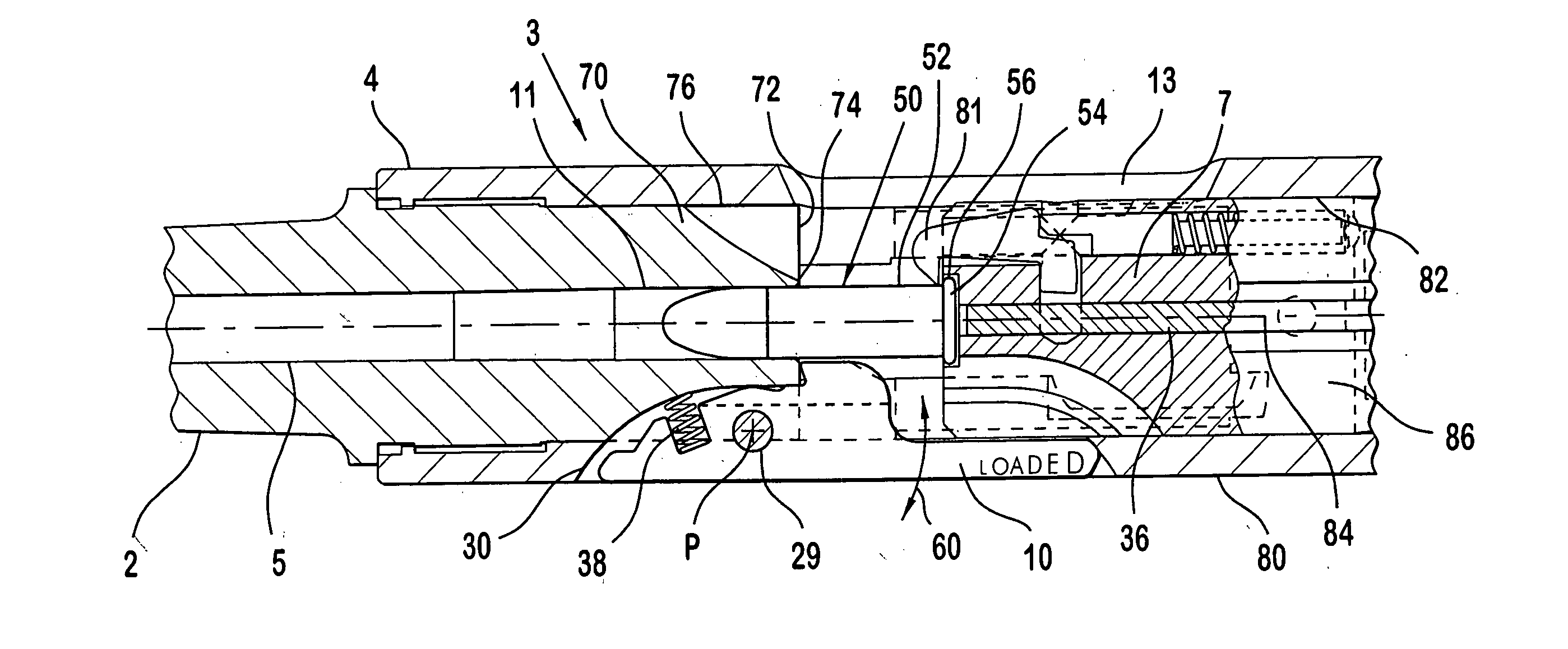

[0038] Pistol 1 includes a longitudinally-extending barrel 2 with longitudinal bore 5 therethrough and a generally hollow-structured receiver 4 in operational relationship with barrel 2. In a preferred embodiment, receiver 4 is disposed adjacent to and preferably attached to barrel 2; the combination defining a barrel-receiver assembly 3. Receiver 4 has an exterior surface 80 and an interior surface 82 defining a cavity 86 therein (see, e.g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com